why making feed pellets for animal and poultry

Before delving into the process of making feed pellets for animals and poultry, let’s discuss why it’s beneficial to do so and the advantages of producing your own feed pellets. according to Wikipedia, Fodder, you can call it also provender, is any agricultural foodstuff specifically to feed domesticated livestock, such as cattle, rabbits, sheep, horses, chickens and pigs.

“Fodder” refers particularly to food given to the animals ( including plants cut and carried to them ), rather than that which they forage for themselves ( called forage ). Feeds include hay, straw, silage, compacted and pelleted feeds, oils and mixed feeds, germinated grains and legumes ( eg sprouts, fresh or used malt ).

video of how to make animal feed and poultry feed

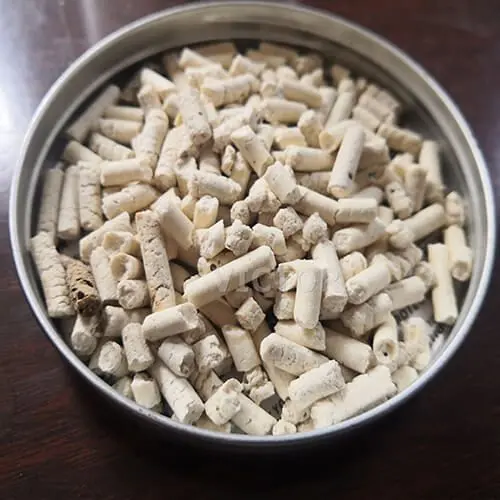

Most animal feed raw materials are from plants, but some manufacturers add animal feed ingredients to processed feeds that are of animal origin. pellet feed as well as small scale poultry feed production have many advantages over mash feeds.

You can produce feed in pellet form with the exact mix of nutrients, vitamins and minerals you need. animals or poultry also consume the whole pellet and all animal feed ingredients in pellet form. With bulk, you can not be sure that all animal feed ingredients have been consumed and ingested.

Enhancing Feed Efficiency and Customization with Animal Feed Pellet Machines

Furthermore, if special medication is necessary, you can proportion a specific number of special feed pellets and be confident that the right amount of medication has been absorbed. Our animal feed pellet machine can produce pellets for small farms, or to produce niche custom feed mixture for sale, with throughputs up to 5000 kg/h. When we say poultry and livestock feed, it’s not just chickens or pigs.

You can make animal pellet feed for other animal such as turkeys, ducks, geese, cows, horse etc. The largest cost component of a poultry production business is feed. So how to make animal feed and how to make poultry feed in a good condition by yourself can help farmers save a lot of costs.

Optimizing Feed Preparation for Livestock: Cutting and Crushing Techniques

Cut straw, sweet potato vines, grass, hay, vegetables, and other feed items into small pieces before feeding them to livestock. Cut cattle straw into 2-3 cm lengths, pig vegetables into 1-2 cm pieces, and sweet potato vines into approximately 1 cm lengths. In general, it is better to cut short rather than long, which is easier for the animal to digest.

Crush cereals, miscellaneous grains, sweet potatoes, and cassava before feeding them to aid digestion. Determine the degree of crushing based on the conditions of livestock and poultry. Crush pig and cattle feed into medium particles of 1~2mm or coarser particles; grind chicken feed into titanium powder.

Cut sweet potatoes and tapioca into pieces, dry them, and then crush them. Utilize a hammer mill for crushing various raw materials such as wheat, corn, rice, soybean, peanut, millet, or other solid materials such as bones, dried meat, etc. Control the final size of the material by inserting sieves with holes of different sizes.

Maximizing Efficiency and Nutrition with Independent Feed Pellet Processing

For long-term storage, silage would be a good choice. Silage is stored in various cellars, ponds and vats and fermented under anaerobic conditions to produce lactic acid. It can ensure the nutrients in the green fodder and improve the utilization rate and digestibility of the green fodder. It is to adjust the surplus and shortage of green fodder season and off-season.

Processing feed pellets independently improves work efficiency for users, reduces feed costs, and increases profits. Users can not only produce cattle and sheep feed pellets but also process feed pellets for pigs, chickens, ducks, etc.

When making feed pellets for poultry and animals independently, users can add different materials according to the varying needs of animals to ensure comprehensive nutrition for livestock and poultry. Feeding pelleted feed can increase the feed intake of animals, avoid animals being picky eaters, and facilitate digestion and absorption. it can shorten the growth period of animals and poultry.

raw materials of making your own feed pellets

The raw materials for making feed pellets include animal protein and vegetable protein. Vegetable protein comes from corn, rice, wheat, soybean, peanut flour, etc.; animal protein comes from fish meal, shrimp meal, crab meal, sleeve fish meal, etc. you can add other poultry feed ingredients according to the needs and eating habits of animals.

how to make feed pellets for animals and poultry

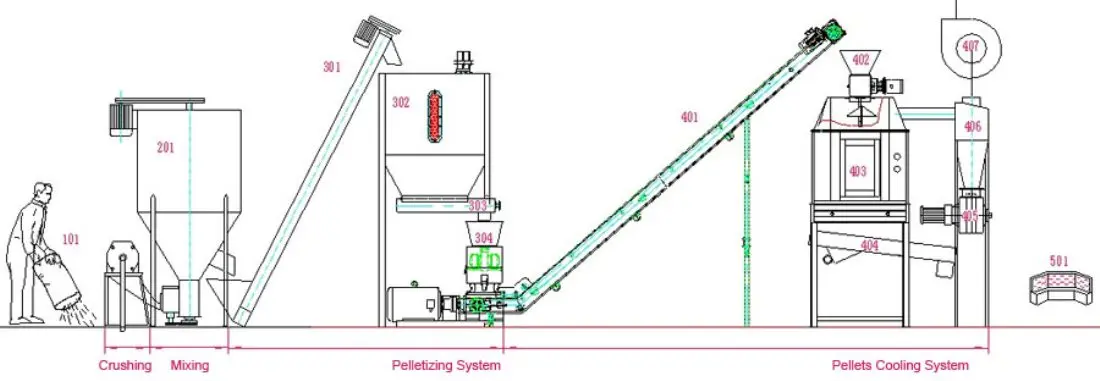

generally there are about 5 steps of how to make poultry feed and animal feed:

First step

First step of how to make animal feed, before making feed pellets for animal and poultry, you must pulverize the raw materials or poultry feed ingredients required by animals into powder by a grain mill grinder machine, such as soybean meal, corn, wheat, vegetables and other materials

Second step

Second step of how to make animal feed, in the mixing machine, you must mix the pulverized raw material powder thoroughly for use in the subsequent granule production process.

During this process, the user can add additives such as vitamins, powders, bones and other necessary trace elements, if you dont want to make your own feed pellet, after crushing raw materials with feed crusher, you can use the feed mixing machine mixing your own feed for animals and poultry.

Third step

Third step of how to make animal feed, the mixed raw material enters the animal feed processing machine through the conveyor. Under high temperature and pressure inside the machine, the loose material is pressed into high-density solid particles of uniform size and shape.

Forth step

Forth step of how to make poultry feed, you need to cool the finished pellet feed and screen in pellet coolers and screeners for later packaging and storage.

Last step

Final step of how to make animal feed, after cooling and sifting, you can bag the pelleted feed for storage. and then you can sell the bagged granules on the market.

flow chart of how to make poultry feed and animal feed