trouble problem of fish feed machine

your floating fish feed machine will come out many different problems after it worked a long time, or because of your wrong operation,your fish feed machine has occured problems or not working well even stopped working.

common problems are low production output, too high puffing or not enough puffing,and poor pellet forming,against these trouble problems, especially on poor pellet forming problem, some of our clients met this kind of problem, some because of raw materials formulation, some because of wrong operation, and in here we will give some troubleshooting and solutions for you.

troubleshooting of fish feed machine

solutions of low production output

1.the screw head is worn greatly, please change the screw head or the whole screw.

2.the bushing of the extrusion chamber is worn greatly, please change the bushing in the extrusion chamber.

3.if you changed the formuation or not? for sinking type pellets:starch content percentage:≥20%, for floating type pellets: starch content percentage:≥10%. In addition: Especially for floating materials, the content of animal protein should not be too high.

The role of starch:

1).Starch has strong water absorption;

2).The gelatinized starch can enhance the viscosity of the material.

3).Double function of puffing and binding in the final pellets.

The role of protein:

1).Protein has water absorption, elasticity and coagulation.

2).Protein splits into vegetable protein and animal protein. Formulas with vegetable protein generally process easier than those with animal protein. Because animal protein is not as easy to combine with other ingredients or bulk as vegetable protein or starch, you can check how to make fish feed.

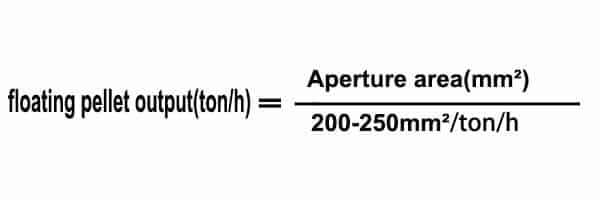

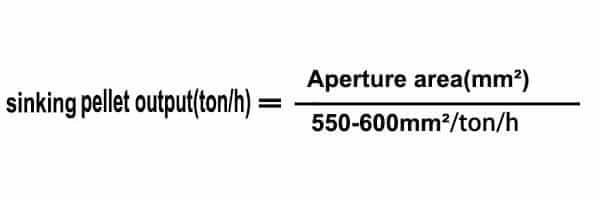

4.is the aperture area of the die is suitable or not?

A=1aperture area area=πr2 , 10holes-8mm die 8mm diameter=4mm redius.

area=πr2 , 3.14×16=50.24mm2

10 holes×50.24=502.4mm2

solutions of Too high puffing or not enough puffing

1.the raw materials are puffed much too highly

1) the conditioner temperature is too high ( for wet type fish feed extruder machine ).

2) the rotation speed of the host machine is too high.

3)too much or too less water added in the raw materials or in the conditioner.

4) the holes of the die mould is blocked.

2.The puffing degree of the material is not enough

1) the extruder production ourput is low.

2) the conditioner temperature is not enough high.

3) the rotating speed of the host machine is too low.

4) the heating plate temperature in the extrusion chamber is too low.

5) water content is too low in the conditioner or in the raw material.

6) have you ever changed the formulation.

3.poor pellet forming

1) the raw materials formulation is not so good.

2) the working temperature is too high or too low.

3) you don’t feed raw materials evenly.

4) the cutting speed is not correct,too high or too low.

5) the cutting blades are worn.

6) the size of powder raw materials is too large,you can check here the raw materials size requirement.

| die mold aperture φ (mm) | grinding fineness required |

| 1.0 | 95% reach to 90-100 mesh |

| 1.5 | 95% reach to 80 mesh |

| 2.0 | 95% reach to 80 mesh |

| 3.0 | 95% reach to 60 mesh |

| 4.0 | 95% reach to 60 mesh |

| 5.0 | 95% reach to 60 mesh |

4.the final pellets are rough surface and different lengths

1) some partial holes of the die mould are blocked.

2) the finness of the raw materials is not enough.

3) the raw materials conditioning is not good.

4) the quality of the die mould holes is poor.

5) the cutting blades are worn.

6) the water percentage in the raw materials is not correct.

5.the extrusion temperature is too low

1) the steam conditioning temperature is too low (for wet type fish feed machine).

2) A blockage occurs in the puffing chamber’s steam inlet pipe, or the electric heating device’s temperature falls short (for wet type machines).

3) Jacketed steam line (trap) plugged( for wet type fish feed machine).

4) The electric heating plate’s temperature is too low, or the electric heating switch remains off.

5) Raw material moisture is too high.

6.Particles are blocked before exiting the die hole

1) The particle size of the raw material is too large relative to the size of the die hole.

2) The amount of water is not enough to make the material flow.

3) the screw rod is worn greatly.

4) The feeding inlet is blocked.

What To Do If Your Fish Feed Extruder Is Running Too Hot?

You should immediately address excessive heat in a fish feed extruder, as it impacts the feed’s quality and the machine’s longevity.

1. Symptoms of Overheating:

First, it’s crucial to recognize the signs that your extruder is running too hot:

- Odd smells or smoke emanating from the machine.

- The final pellets discolored or appear scorched.

- The machine’s exterior is too hot to touch safely.

2. Potential Causes:

Overheating can occur for several reasons:

- Friction: Excessive friction within the machine may generate additional heat.

- Improper Lubrication: Lack of proper lubrication can also lead to overheating.

- Excessive Load: Running the machine at full capacity for an extended period.

- Faulty Cooling System: A malfunctioning cooling mechanism can lead to temperature imbalances.

3. Immediate Actions:

When you notice your fish feed extruder is running too hot, you should:

- Shut Down: Safely power off the machine to prevent any potential damage.

- Inspect: Visually inspect for any visible issues like blocked vents or leaking lubricant.

- Consult the Manual: Always check the user manual for troubleshooting tips specifically designed for your model.

4. Long-term Solutions:

- Regular Maintenance: Frequent checks and proper lubrication can prevent overheating.

- Replace Worn Parts: you should replace any worn-out bearings, gears, or other parts.

- Cooling System Check: Ensure the cooling system is functioning correctly, and consider upgrading if needed.

5. Consult a Technician:

If the issue persists, it’s advisable to consult a qualified technician for a thorough inspection and necessary repairs. A professional will be able to identify the root cause of the problem and recommend a suitable solution.

6. Review Operational Procedures:

Consider revisiting your operational guidelines. Ensure you train your team to identify and respond to such issues promptly. An awareness program can be beneficial.

7. Monitor and Record:

Once you resolved the issue, continuously monitor the machine’s temperature during operation for some time to ensure that the problem doesn’t recur.