| Price | 23000-250000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Poultry Feed Line: 0.5-15T/H Capacity

| Production Output | 0.5-15 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal, leaf, fish meal, grass meal, hay meal, etc |

| Type | flat die type and ring die type |

| Final Pellet Size | 2-10 mm |

| Application | feed production |

| Used For | chicken food production, bird food production |

Automated Pelletizing: 4mm poultry Feed production video

poultry feed production line: From Crushing to Automated Packaging

This poultry feed production line can make food pellets for chicken, hen, broiler, duck, bird. it is fully automatic plant. it can work good for small farming, large farming, and commerical food plant.

The poultry feed business is growing fast. people at now like to choose pellet forage. it keeps birds healthy with full nutrition. pellet forage is easy to digest. they can be stored well and moved easily. the raw materials can be grass meal, straw meal, vitamins, hay meal, corn meal etc.

We are good at poultry feed production plant with many years experience. we have more than 10 engineers. They make good designs. make top quality gears just for you.

the feed manufacturing plant makes same-size pellets with less dust. it is made of stronger metal plates. you can pick what fits your need.

small poultry feed production line

small poultry feed production line

features of poultry feed processing line

This poultry feed production plant can make different pellet sizes. it can handle 1 ton per hour, up to 15 tons per hour.

We can design the poultry food production line as per your need. it will fit any farming needs. and works with all raw materials. we will match your budget. Add machines you need. Take out what you don’t.

Pellets come out smooth and tight. No bad germs. Helps birds to grow stronger and healthier.

We have best after-sales service. give you biggest support. we can send experts to your site for installation. Train your workers. Keep the food lines running right.

advanced technology poultry feed production line can make 1000 to 3000 tons forage each year. the poultry feed production line day and night. but uses less power.

PLC runs the show. Our smart system watches and runs it all.

Large poultry food production line

Large poultry food production line

the poultry feed manufacturing plant can make fodder for chickens, cows, pigs, and fish. Works great for small and large farms.

All controls in one spot. Machines work safe together. Auto stop if trouble. Press buttons to run. Easy to use.

the poultry feed production line is built in blocks. the feed processing plant has small size. it takes little room and costs less money. Box-like setup and put up fast.

raw materials for poultry feed production line

Corn, maize, soybean, rice, wheat all these grains have 10-14% protein. they are full with B1, B2, B6 vitamins. Some enzymes inside.

Rapeseed meal, cottonseed meal are full with protein. good for cows and chickens. Each meal gives about 38% protein. Also has 12% crude fiber. Contains special compounds from mustard family.

straw meal, grass meal, rice bran, wheat chaff: contain fiber, control many types of diseases.

application of poultry feed production plant

This poultry feed production line does many jobs. What it does depends on needs. Makes all types of fodder for chicken, duck, bird etc. also works for fish fodder too.

large food pellet plant usually use this poultry feed processing plant. poultry farmings always use them too. Machines work on their own. Make lots of food fast.

the poultry feed production line has grinders, blenders, pellet mills, storage tanks, sifters, baggers. We design this plant for your stuff and needs.

this line can make forage for chicken, duck, bird etc and other birds and livestock.

Turns fodder scraps into fodder. Makes pellets from green waste. Feeding cows and chickens.

turning straw, grass, hay meal into pellets for bird fodder and heating fuel.

Corn, soybean, rice, wheat do not need to crush at first. Just put these grains into the pellet machine. Watch them turn into fodder pellets on their own.

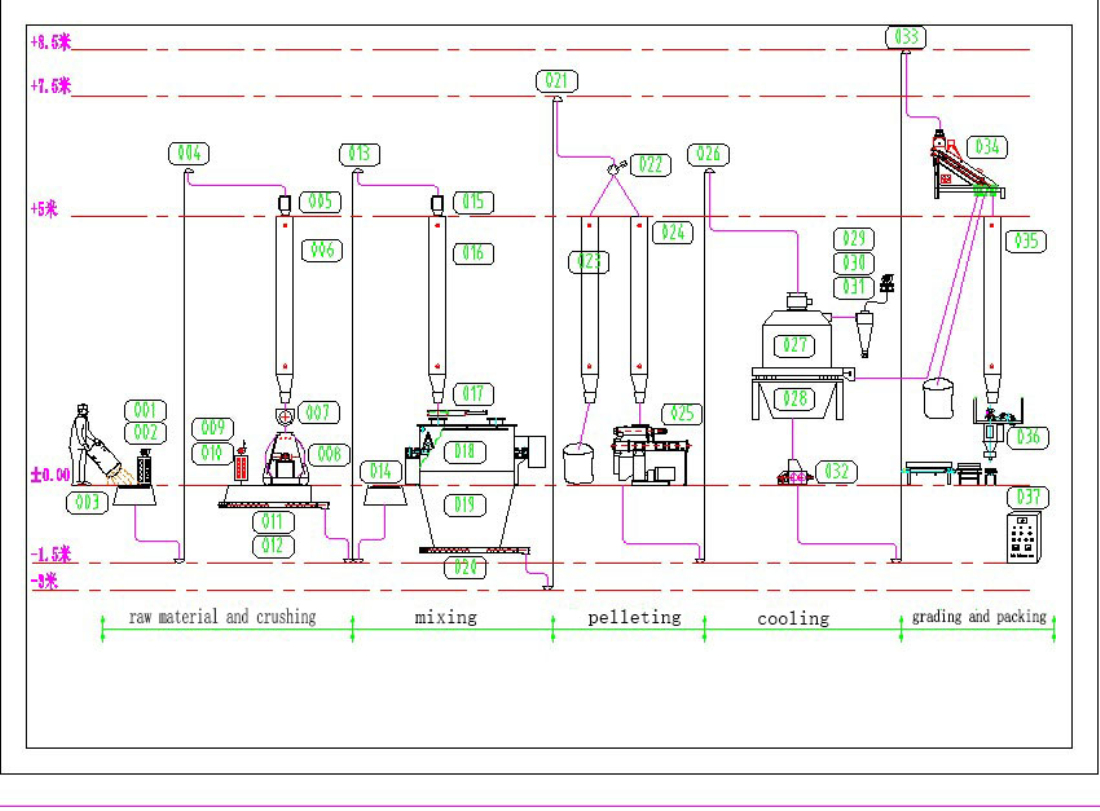

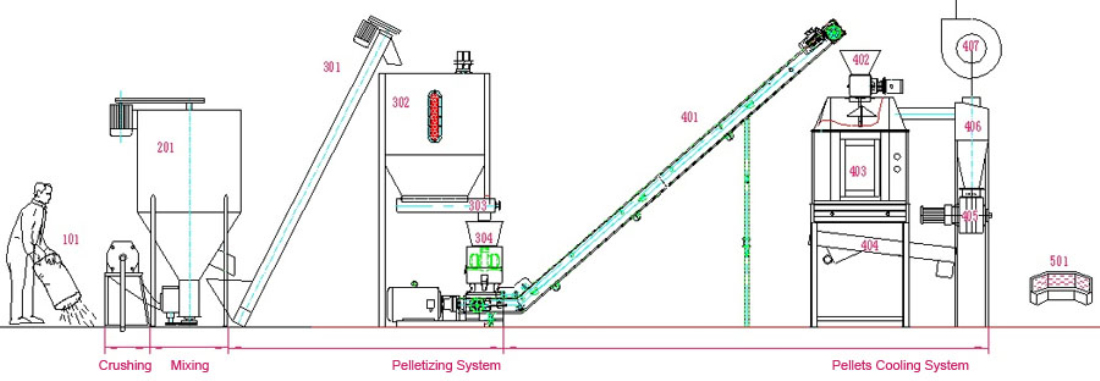

poultry feed production process

for small capacity

for large capacity

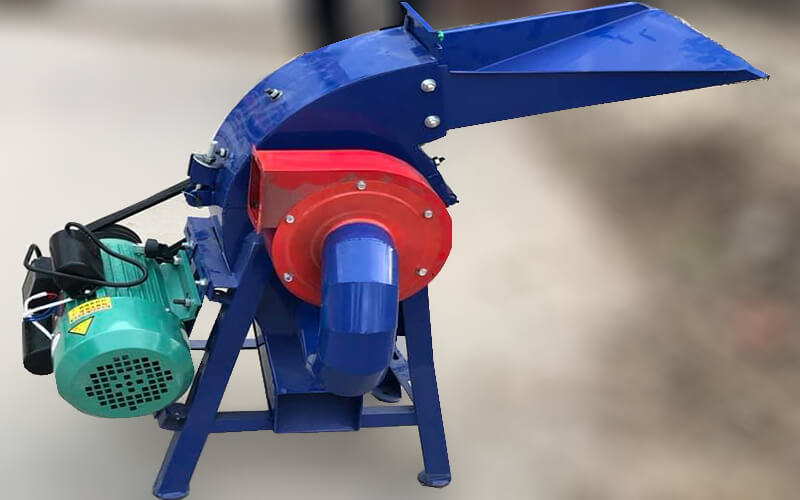

Crushing Process: Hammer Mill Crusher

hammer mill crusher is suitable to grind raw materials into powder with optimal size for best pelletizing effect.

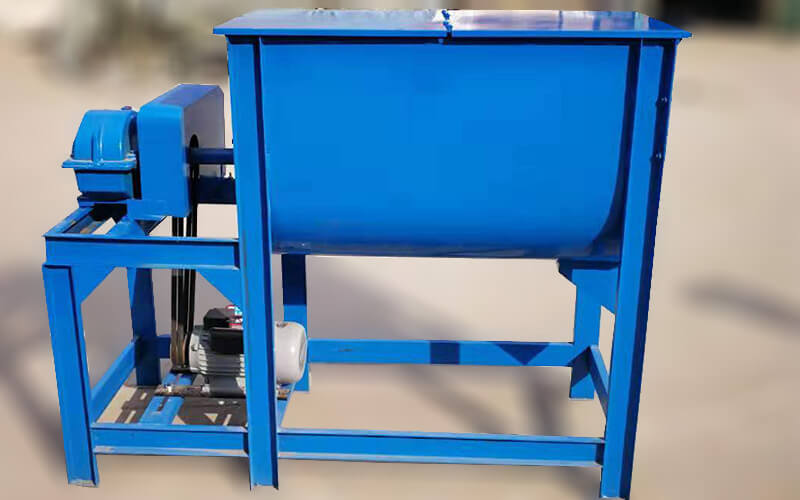

Mixing Process: Mixer Machine

The crushed materials are lifted to the high-level silo, and then the materials from different silos are put into the mixer for mixing.

Pelletizing Process: Flat Die or Ring Die Pellet Mill

Move the mixture up again. Put it in the pellet mill. Watch the machine close. This step makes pellets work right.

Cooling Process: Cooling Machine

finished pellets temperature is high about 75-85°C. Steam makes the air wet. the pellets are warm and damp. They hold 16-18% moisture. This makes pellets to bend or crack easily.

They may clump and grow mold. To keep them safe, you need to dry pellets under 14% moisture. and cool them to 8°C below room temp.

Packing Process: Packaging machine

The last step is to pack them. Good pellets pass the test. They go into bags for ready to ship. This will keep fodder safe and easy to transport.

poultry feed manufacturing process flow chart

for small production capacity

for large production capacity