| Price | 500-3000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Feed Pellet Machine Specifications: Power, Output & Materials

| Production Output | 0.1-2 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | rice, corn, wheat, barley, soybean, oil seed, leaf, fish meal, straw etc |

| Type | flat die |

| Final product size | 2-12 mm |

| Application | feed pellet |

| Used For | animal feed production |

Electric vs. Diesel Feed Pellet Machines: Model Comparison

electric feed pellet mill

| Model | Electric Power(kw) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 3 | 50-80 | 80 |

| VTKLP-150 | 4 | 100-150 | 110 |

| VTKLP-210 | 7.5 | 200-400 | 210 |

| VTKLP-230 | 11 | 300-500 | 280 |

| VTKLP-260 | 15 | 500-700 | 300 |

| VTKLP-300 | 18.5 | 700-900 | 500 |

| VTKLP-360 | 22 | 900-1200 | 700 |

| VTKLP-400 | 30-37 | 1200-1500 | 900 |

diesel engine feed pellet mill

| Model | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 4 | 50-80 | 100 |

| VTKLP-150 | 5 | 100-150 | 150 |

| VTKLP-210 | 10 | 200-400 | 260 |

| VTKLP-230 | 15 | 300-500 | 350 |

| VTKLP-260 | 20 | 500-700 | 420 |

| VTKLP-300 | 25 | 700-900 | 650 |

| VTKLP-360 | 30 | 900-1200 | 900 |

| VTKLP-400 | 40-50 | 1200-1500 | 1200 |

animal feed production video

What is a Feed Pellet Machine? Functions & Nutritional Benefits

An animal feed pellet machine is a piece of equipment that turns various raw materials into a uniform and compact feed pellets for animal and livestock. Its main purpose is to allow animal farmers and homeholders to make their own animal feed. They can control fully over their animals’ nutrition an proteins. The machine can process different materials like corn, soybean, wheat, fish meal, grass, rice bran and other essential vitamin and mineral premixes.

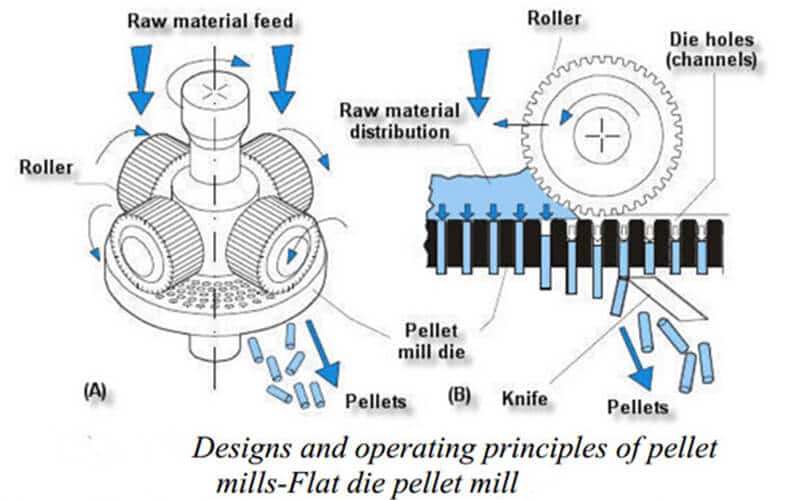

How Does It Work? The Core Function

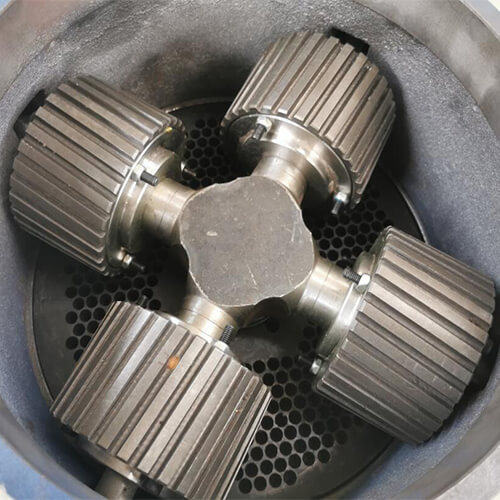

The animal feed pellet machine working principle is a process of high pressure and heat between roller and die. First, the mixed raw ingredients are fed into the chamber of the machine. Inside this chamber, the rollers assembly presse the material with the die under great force pressure.

This extreme pressure compacts the loose powder ingredients into dense and solid pellets. The friction between rollers and die during the process naturally generates a significant amount of heat and pressure. This makes pellets high quality and safety for animals.

The Key Nutritional Benefits of Pelletized Feed

Making feed by this process offers several important nutritional benefits. First, the heat during pelleting can reach to 70-80°C, it can pasteurize the feed. This process helps to kill harmful bacteria like Salmonella that might be in the raw ingredients. This will make the food safer for your animals.

Second, this heat and pressure can improve the digestibility of starches in grains. It makes the energy in the feed more available to the animal’s digesting system.

Finally, because every single pellet contains the complete and balanced nutrition, it prevents a common problem known as selective feeding. This ensures animals eat every bit and receive all the necessary nutrients, rather than just eating their favorite feed.

Feed Pellet Technology Advancements: Mold Customization & Force Control

Our engineers made this animal feed pellet machine better using world-class technology. The gear system has truck-tough parts that move power without belt slips. Workers can quickly change molds to make 2mm to 10mm food bites for sheep, pig, cattle and other farm animals.

This strong animal feed machine uses high force for all-day work. Eight special molds let farmers switch between pellet sizes fast. Smart heat control keeps every pellet the same hardness, perfect for baby chicks or grown cows.

electric feed pellet mill

diesel engine feed pellet mill

Scalable Feed Production: 50lb/h to 1200lb/h Capacity Options

This animal feed maker machine has different models for every farm. The small models make 50 to 200 pounds of food per hour, it is perfect for backyard chickens or home use. large models can make up to 1200 pounds per hour, which is enough for large farming.

Choose between plug-in electric power or tough diesel engines that work anywhere. Like having a mini food factory, the animal feed pellet machine grows with your farm.

You can at first start with the 50-80lb size, then upgrade to 1000lb+ models when your flock expands. All versions use farm-tested gears that keep running year after year.

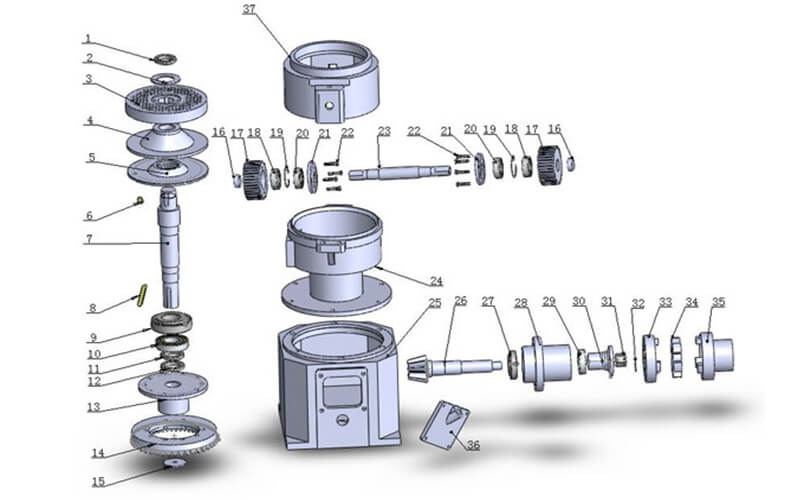

Key Components: Flat Die, Rollers & Cutting System

The animal feed pellet machine has important parts that work together. These parts are power box, feeding bin, discharging bin, rollers, and die. electric motor helps the machine work with more power at a slower speed. The hole size of the die can be changed to meet different needs.

Flat Die

The flat die is the main part to shape pellets. It is fixed in the animal feed machine and has many small holes. The die’s thickness and hole size decide how big and strong the pellets become.

Tt also decides the production capacity, for example, 5mm size may only be 200kg/h. Tough metals keep it working for long time. The die lifetime can be about 800 hours.

Pressing Rollers

These round rollers work with the flat die. Most animal feed pellet machine uses 2-3 rollers. They push prepared materials through the die’s holes while spinning around its center.

Cutting Tools

The blade under the die cut pellets into the right length. People can adjust the blades to make pellets longer or shorter as needed.

Power System

This gives energy to the whole machine:

- Electric motor creates movement

- Gearbox makes power stronger

- Rubber belts send power to parts

Oil System

You need to add oil to lubricate parts like bearings to keep parts moving smoothly. This will help the animal feed pellet machine last longer.

Control Panel

It is like the machine’s brain. Workers can use buttons or touchscreens to adjust settings. Clear screens show how the machine is working.

65-70℃ Precision Heating for Safe Feed Pellets

Materials go into animal feed pellet mill through a hopper. Inside, heavy rollers press them against the flat die with holes. This pressing happens at high temperatures between 65 and 70 degrees.

The heat helps make animal food pellets better and safer. The machine has electricity control box, you can operate it through the easy buttons. This helps the machine work with its best. You can operate it simply to control how the pellets are made.

Animal Feed Pellet Machine Price for Home and Commercial

Animal feed pellet machine price varies on different size and capacity. Small machines for home use usually cost between USD 500 and USD 2,000. they are better for home use or small farming. These work well for making food pellets for chickens or other animals.

Bigger feed pellet mill may cost over USD 10,000. They are better for large farming or commercial use. Feed factories and large farming often need such heavy-duty machines. The machine size and production capacity affect the price of the feed making machine.

Smallest feed pellet mill has low cost, it is sometimes just a few hundred dollars. You should always check how much animal food you need to make before choosing.

4 Cost Factors: Size, Controls, Durability & Brand

Animal feed pellet machine cost different amounts for four key reasons. Bigger machines that make more pellets cost more. Small machines work for family farms feeding chickens.

Huge machines is better for large factories. Machines with smart computer controls cost more at first. But they save money later by using less electricity. Some have easy screens to help make perfect pellets.

The animal feed pellet mill is made with strong steel, it can work for long time. They cost more and break less.

Known brands with good repair support cost more. The supplier who make feed pellet mill for over 10 years usually help to fix problems faster.

Considerations When Buying Animal Feed Pellet Machine

When you choose an animal feed pellet machine, you should know how much food you need each day. Then choose the right equipment and avoid paying more than you need. Besides think about how much electricity it uses and how often it needs fixing.

Find supplier who supply high quality machines, and can help to fix them when they are break. Different animals like chicken, cattle, rabbit need different pellet size. You should make sure the machine can make different pellet size.

When you buy the animal feed machine, you should make sure if the spare parts are easy to get. Large machines may need special help from the supplier. Good suppliers can send spare parts quickly when you need.

High quality animal feed making machine is made with tough steel and can work for longer time. You should look for materials that don’t wear out fast.

Choose the animal feed pellet machine that has simple operation buttons and cleaning steps. This can save you time and reduce mistakes. The machines with less power can save you money on electricity.

Intelligent Equipment Selection System

| Farming Scenario | Recommended Model | Daily Output (kg) | Daily Energy Cost | ROI Period | Upgrade Path |

|---|---|---|---|---|---|

| Household Farming | |||||

| 500 Laying Hens | VTKLP-125 | 80-120 | $ 2.4 | 8 Months | → VTKLP-210 |

| 20 Pigs | VTKLP-150 | 150-200 | $ 3.6 | 10 Months | → VTKLP-230 |

| Medium Farm | |||||

| 1,000 Broilers | VTKLP-210 | 300-400 | $ 7.2 | 14 Months | → Dual VTKLP-260 |

| 50 Dairy Cows | VTKLP-260 | 700-900 | $ 16.8 | 18 Months | → VTKLP-400 + Automation |

| Enterprise Level | |||||

| 100,000 Poultry | VTKLP-400 ×3 | 3,600 | $ 86.4 | 24 Months | Custom Production Line |

High-Protein Raw Materials for Nutrient-Rich Pellets

Grains like corn, wheat, rice, soybean have rich protein with 10-14%, they are best for animal growth. These grains also are rich with B vitamins like B1, B2, B6. These vitamins can help animals digest food better.

Meals from rapeseed and cotton plants are protein-rich feed ingredients. They contain about 38% protein. They are great to help animals to build muscle. But these also have 12% rough fiber and special plant compounds from the mustard family.

Some animals may need more care when they eat their food. Grassy materials like straw, rice bran can help animals to stay much healthier.