| Price | 500-8000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Poultry Feed Pellet Machine: 0.1-2T/H Capacity & Dual-Power Options

| Production Output | 0.1-2 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal, fish meal, kinds of powder, etc |

| Type | flat die type |

| Final product size | 2-10 mm |

| Application | pellet production, pellet industry |

| Used For | poultry feed, chicken feed |

Electric vs Diesel poultry feed pellet machine specifications

electric motor type

| Model | Electric Power(kw) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 3 | 50-80 | 80 |

| VTKLP-150 | 4 | 100-150 | 110 |

| VTKLP-210 | 7.5 | 200-400 | 210 |

| VTKLP-230 | 11 | 300-500 | 280 |

| VTKLP-260 | 15 | 500-700 | 300 |

| VTKLP-300 | 18.5 | 700-900 | 500 |

| VTKLP-360 | 22 | 900-1500 | 700 |

| VTKLP-400 | 30-37 | 1500-2000 | 900 |

diesel engine type

| Model | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 4 | 50-80 | 100 |

| VTKLP-150 | 5 | 100-150 | 150 |

| VTKLP-210 | 10 | 200-400 | 260 |

| VTKLP-230 | 15 | 300-500 | 350 |

| VTKLP-260 | 20 | 500-700 | 420 |

| VTKLP-300 | 25 | 700-900 | 650 |

| VTKLP-360 | 30 | 900-1200 | 900 |

| VTKLP-400 | 40-50 | 1200-1500 | 1200 |

Pelletizing video: 5mm poultry Feed

what is poultry feed pellet machine

A poultry feed pellet machine is a feed making system that you can use it to make your own poultry feed. You can fully control over the feed nutrition that poultry need. The machine can process different kinds of raw ingredients and uses high pressure to press them into solid and nutrient-rich pellets.

This process is often called pelletizing. Making pellets can bring a lot of great benefits. It makes the feed easier for poultry to digest. Also greatly reduces the food waste that is common with loose and powdered feed.

What Can This Machine Do?

This machine feature is that you can change the die easily for making different size of pellets. By using different dies, you can make small pellets with 2mm-3mm for yong chicks, and 4-5mm for adult chickens.

You can also make a much larger 8mm pellet for adult cattles. A good poultry feed pellet machine for a small farm can typically produce between 100kg and 1,000kg of feed per hour, depending on its size and power.

What Ingredients Can It Use?

These poultry feed pellet machines can turn many different raw materials into complete feed. You can use common grains like maize, soybean, wheat etc as raw materials. For fiber, you can add things like grass, hay, alfalfa, or even rice husks.

By adding your own protein sources, vitamins, and minerals, you can create a perfectly balanced diet for your specific poultry. This allows you to use local or low-cost ingredients to manage your expenses.

Choosing Your Power Source

These versatile poultry feed pellet machine often offers two power options. You can choose a model that runs on an electric motor. This is great if you have a reliable power source in your barn or workshop.

You can also choose a model that runs on a diesel engine. This gives you the freedom to make feed anywhere on your property, even far from a power outlet. The right choice simply depends on what is most convenient and cost-effective for your farm.

electric motor type

diesel engine type

Key Benefits of Making Your Own Feed Pellets

Investing in a feed pellet machine offers more than just fresh food for your poultry. It provides a range of cost-saving and operational advantages that can make your farm more efficient and profitable. From lower costs to healthier poultry, the benefits are significant.

Lower Upfront Investment and Easy Setup

Unlike large, industrial feed mills, these machines are designed with a small footprint. They do not require a huge, dedicated workshop. You can often set one up in the corner of an existing barn. Their design is typically simple and modular.

This means that installation is fast and does not require a team of expensive technicians. Most farm owners can get their machine running quickly, saving a great deal of money and time on setup.

Reduced Daily Operating Costs

These machines are built to be highly efficient. Most models are designed for one-person operation, which significantly reduces your daily labor costs. You can also choose a poultry feed pellet machine powered by an electric motor or a diesel engine.

This allows you to use whichever energy source is cheaper or more available on your farm. Furthermore, by making feed yourself, you can buy raw ingredients in bulk when prices are low and avoid the high costs of shipping and handling associated with commercial feed.

Flexibility to Feed All Your Poultry

One of the greatest benefits is the machine’s versatility. While it works perfectly for poultry, its true value is feeding many different poultry. By simply swapping out the metal die, you can change the size of the pellet.

You can make a small, 2-3mm pellet for your chicks, then switch to a larger 8mm die for adult chickens or cattles. This means a single, affordable machine can support the nutritional needs of your entire farm.

Improved Poultry Health and Nutrition

The process of making pellets also helps protect your poultry. During pelletizing, the feed is put under intense pressure and heat, often reaching 80-100°C. This heat effectively sterilizes the feed.

It kills most common molds and harmful bacteria, such as E. coli or Salmonella, that can be found in raw ingredients. Giving your poultry clean, high-temperature-treated feed leads to better overall health, which can mean fewer illnesses and lower veterinary bills.

Key Features of a High-Performance poultry Feed Pellet machine

A reliable feed pellet machine is defined by the quality of its engineering. The best machines are built with specific features designed for durability, consistent performance, and ease of use. Understanding these features will help you choose a machine that provides lasting value for your farm.

Built to Last: Advanced Alloy Steel Components

The durability of a pellet machine comes from its core materials. The most critical parts—the flat die and the roller that press the feed—are not made from common steel. They are forged from a specialized Chromium-Molybdenum-Vanadium (Cr-Mo-V) alloy.

This advanced metal is then heat-treated to achieve a very high surface hardness of HRC 58-62. In simple terms, this makes these parts extremely resistant to the intense pressure and friction of making pellets, ensuring they do not wear out or deform quickly.

The Long-Term Value: A Cost-Benefit Analysis

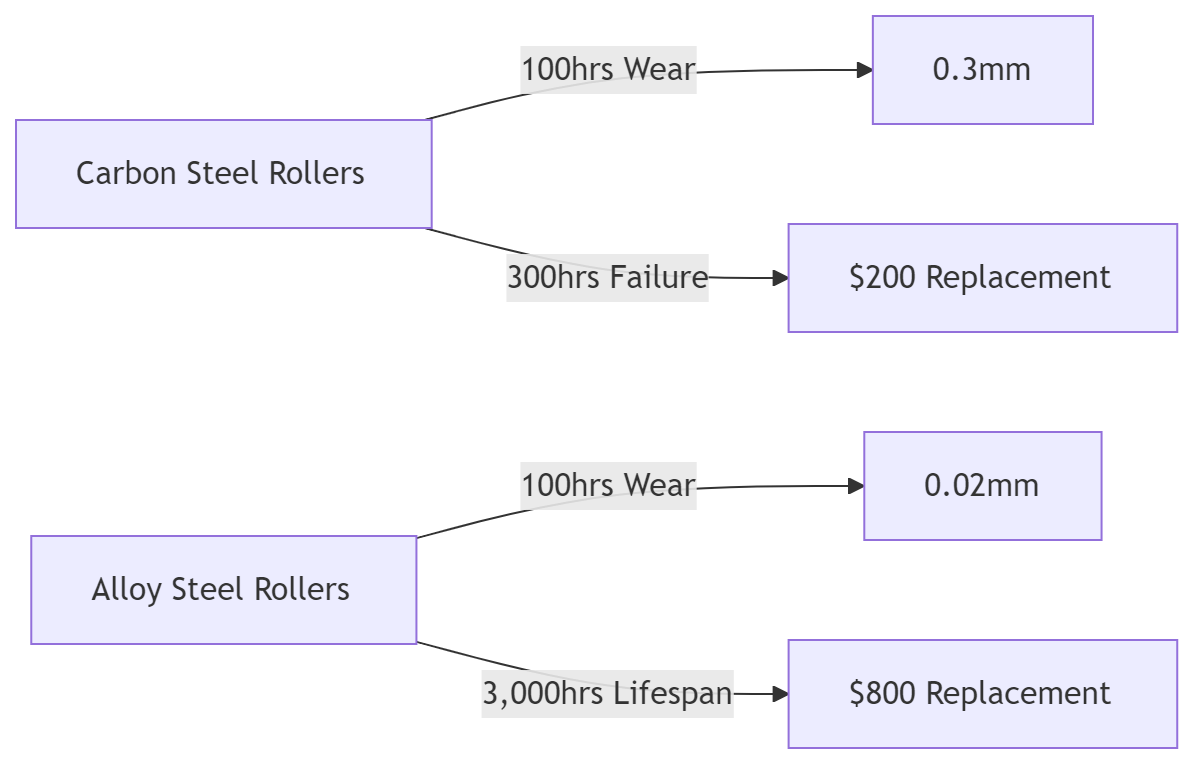

This choice of advanced material directly impacts your long-term costs. For example, a basic carbon steel roller might wear down by 0.3mm after just 100 hours of work and would likely need a full replacement after 300 hours. In contrast, the superior alloy steel roller shows almost no wear—just 0.02mm—in the same 100 hours.

It is engineered to operate for over 3,000 hours before needing a replacement. Even if the alloy part costs more upfront, its incredibly long life makes it far cheaper over time by saving you money on spare parts and costly downtime.

A Stable Drive System for Reliable Power

A powerful motor is only effective if the power is transferred smoothly. These machines use a heavy-duty drive system, using principles similar to an automotive gearbox. High-quality gears and belts transfer power from the motor to the rollers with very little energy loss. This stable and efficient system ensures the machine maintains consistent pressure and speed, which is the key to producing uniform, high-quality pellets.

Designed for Easy Maintenance

A well-designed machine is also easy to maintain. Regular upkeep is simple and does not require you to be a specialist mechanic. The key tasks are straightforward. You need to lubricate the moving parts through easily accessible grease points. You should also keep the machine clean from dust and periodically check the drive belts for proper tension. Following these simple maintenance steps will keep your machine running reliably for many years.

A Range of Power Options to Fit Your Farm

Every farm has unique power needs. That is why these machines are available in a wide range of power ratings. You can find small 4HP models that are perfect for hobby farms, all the way up to powerful 50HP units for larger agricultural operations. You also have the flexibility to choose your preferred power source. Most model lines offer options for electric motors, gasoline engines, or diesel engines to match what is most convenient and cost-effective for you.

An All-in-One Solution: poultry Feed and Biomass Fuel

This versatile machine offers value that goes far beyond just one purpose. It is engineered not only as a complete feed production system but also as a tool for creating renewable energy. This dual-purpose capability allows you to support both your poultry’s nutritional needs and your farm’s energy needs with a single, efficient piece of equipment.

A Complete Poultry Feed Pellet machine

This poultry feed pellet machine is designed to simplify your entire feed production process. One of its most significant cost-saving features is the ability to process many types of whole grains directly. This means you may not need to buy and operate a separate hammer mill to grind your ingredients first.

The intense pressure from the machine’s roller and die is powerful enough to break down and compact the materials into a uniform pellet. The result is a smooth, dense pellet that locks in nutrition and is easy for your poultry to digest.

More Than Feed: Creating Biomass Fuel Pellets

Beyond poultry nutrition, this machine can be a key part of your farm’s energy solution. With the correct setup, such as a specialized biomass die and roller, it can turn agricultural waste into valuable fuel. Materials like wood shavings, straw, or corn stalks can be compressed into dense biomass pellets.

This process requires a much higher compression ratio than making feed, and this poultry feed pellet machine’s durable construction is built to handle that demand. This allows you to transform farm waste into a low-cost, renewable fuel source for heating your home, greenhouse, or workshops.

Poultry Feed Pellet Machine Price Range

Small machines price are from USD500 to USD1000. Medium capacity machines need USD2000-USD5000. Large machines need USD10k+. But they do more work.

What Affect the Price of Poultry Feed Pellet machine

Poultry feed pellet processing machine prices range from USD500 to USD8,000 based on these critical elements:

1. Machine Power

5-10HP models cost USD1,200-USD3,500 for small farms and home use. Industrial use 50-100HP systems reach to USD4,000 with heavy-duty motors.

2. Die Thickness

3mm dies make soft chicken food. 8mm+ hardened steel dies handle cattle food, adding 18% to total costs.

3. Automation Level

Basic small machines start at USD800. PLC-controlled units with auto-lubrication cost USD1,000+ but cut labor by 40%.

4. Production Capacity

100kg/h machines average US1000. 1ton/h commercial use systems reach to USD35,000.

5. Material Quality

Carbon steel bodies save 25% upfront but wear 3X faster than stainless steel models.

Pro Tip: Request ISO 9001 certification and minimum 2-year warranty when comparing quotes.