what is ring die pellet mill

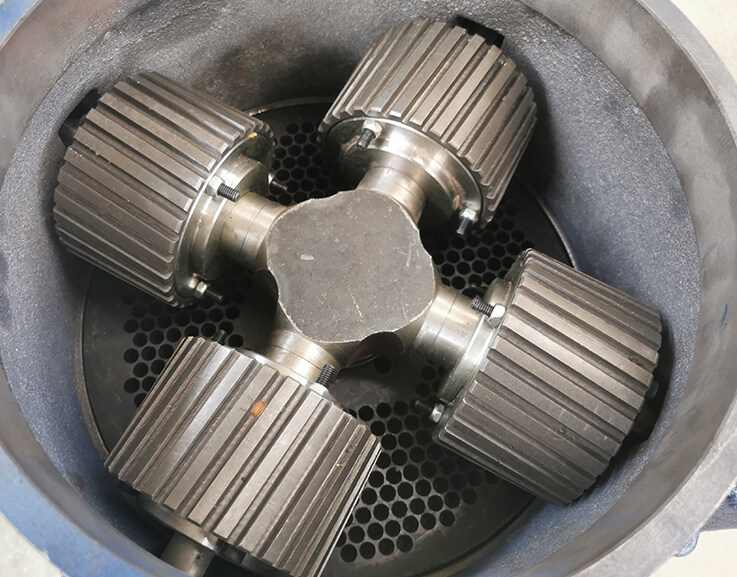

Before discussing flat die vs. ring die pellet mill, let’s define them. A ring die pellet mill has a circular “die” as its main component, with 2 rollers rotating inside. These rollers extrude raw materials through die holes to form cylindrical pellets. Ring die pellet machine is widely used in granulation industry and large feed mill plant.

The shape of the outer mold granulator is a wide cylinder, and the mold is vertical. Due to the high cost and large volume, it is not as common as flat die pellet machine.

Small ring die pellet machine are commonly used in the granulation business and other commercial purposes. As a professional Chinese manufacturer, we supply high-quality small ring die feed pellet mills and specially matched ring die granulators. So you don’t have to worry about finding the right molds, rolls and other consumables.

video of ring die pellet mill

specification of ring die pellet mill

| Model | Power(Kw) | Output(kg/h) | Feeding Power(kw) | Conditioner Power(kw) | Ring Die Diameter(mm) | Pellet Size(mm) |

| HMK-250 | 22 | 500-1000 | 0.55 | 2.2 | 250 | 1.5-8 |

| HMK-300 | 30 | 1000-2000 | 0.75 | 2.2 | 300 | 1.5-8 |

| HMK-320 | 37 | 2000-3000 | 0.75 | 2.2 | 320 | 1.5-8 |

| HMK-350 | 55 | 3000-4000 | 1.5 | 3 | 350 | 1.5-8 |

| HMK-400 | 75 | 4000-5000 | 1.5 | 5.5 | 400 | 1.5-8 |

| HMK-420 | 110 | 5000-8000 | 1.52.2 | 5.5 | 420 | 1.5-8 |

what is flat die pellet mill

Flat die pellet mills are compact, designed for making feed and wood pellets. With a 200 mm die diameter and adjustable hole sizes, they convert wastes into pellets, such as sawdust and straw.

These mills are low-noise, efficient, and versatile, perfect for small to medium production. The flat die suits sinking fish feed, whereas floating feed requires a floating fish feed machine.

Flat die pellet machine relies on flat die to granulate various raw materials. Different raw materials have different densities, and different types of particles have different densities according to their functional needs.

For example, animal feed pellets are not as hard as fuel pellets. Therefore, different types of pellets and different pellet feedstocks require different flat die dies. The higher the compression ratio, the denser the particles produced.

But if the compression ratio is too high, the material may clog the mold. To make high-quality pellets, use a flat die mill with the right compression ratio for your material. This mill makes both feed and wood pellets.

video of flat die pellet mill

specification of flat die pellet mill

| Model | Electric Power(kw) | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 3 | 4 | 50-80 | 80 |

| VTKLP-150 | 4 | 5 | 100-150 | 110 |

| VTKLP-210 | 7.5 | 10 | 200-400 | 210 |

| VTKLP-230 | 11 | 15 | 300-500 | 280 |

| VTKLP-260 | 15 | 20 | 500-700 | 300 |

| VTKLP-300 | 18.5 | 25 | 700-900 | 500 |

| VTKLP-360 | 22 | 30 | 900-1200 | 700 |

| VTKLP-400 | 30-37 | 40-50 | 1200-1500 | 900 |

flat die vs ring die pellet mill

Wikipedia states pellet mills fall into large and small scale categories. They vary by capacity into flat die and ring die types. Flat die mills feature multiple holes; the die compresses materials fed into it through these holes while rotating.

A cutter on the other side of the mold will cut the exposed particles out of the mold. Ring die pellet mill use ring dies with radial grooves. The material is first fed into the inside of the mold and distributed evenly by the spreader. Then, two rollers will compress them through the die hole, and two cutters will trim the particles exiting the die.

Large Scale

Large scale pellet mills are mainly of two types: flat die and ring die. Ring die mills are larger, while flat die mills use a slotted die. Powder fed into the top is pressed through the holes by a rotating die’s roller.

A cutter on the other side of the die cuts the exposed pellet free from the die. In the ring die there are radial slot throughout the die. Powder is fed into the inside of the die and spreaders evenly distribute the powder. Two rollers then compress the powder through the die holes. Two cutters are used to cut the pellets free from the outside of the die.

Small Scale

Small scale mills often use screw or hydraulic presses. The flat die mill is one such small scale option. Both types use a die or mold to shape uncompressed powder in a pocket, which defines the pellet shape. A platen, attached to a screw (in screw presses) or a ram (in hydraulic presses), compresses the powder.

ring die pellet mill parts: roller and die

ring die pellet mill rollers

ring die pellet mill die

flat die pellet mill parts: roller and die

flat die pellet mill rollers

flat die pellet mill die

difference between flat die pellet mill and ring die pellet mill

Feeding Method:

The ring die granulator adopts mechanical feeding method. The raw material enters the granulation chamber at high speed by means of rotary centrifugation.

Pellet Formation:

Flat die mills use a perforated disk with rollers that force material through holes to make pellets. Ring die presses have a rotating ring and rollers that press material into pellets along the inner edge.

Adjustment of the rollers:

The ring die pellet granulator adjusts pressure with two screws on the eccentric gear in the roll center. The flat die granulator adopts the way of center adjusting screw. It bears hundreds of tons of top pressure, falls smoothly, hits softly, and presses evenly.

Different Pressure:

With the same die size, the ring die granulator’s rollers face limits, impacting pressure. The flat die granulator’s pressure is adjustable. The flat die diameter is not limited by the die diameter, which can expand the inner bearing space. The use of large bearings not only enhances the bearing capacity of the rollers, but also prolongs the service life.

Production Capacity:

The flat die granulator’s output is around 80-1000 kg/hour, whereas the ring die granulator’s is 500-8000kg/hour.

Purchasing Price:

Flat die pellet mills are small, lightweight, and have low capacity, making them affordable and popular for home use or small farms. Ring die mills are larger, heavier, and have higher capacity but are more expensive, suitable for commercial use.

Power Source:

Flat die pellet machines work with electric or diesel motors. Ring die machines use only electric because their shaft structure doesn’t support diesel.

flat die vs ring die pellet mill which one is better?

No choice is best; both have pros and cons. Choose between flat die and ring die mills based on your needs. The flat die pellet granulator machine has low energy consumption and high fluidity, and is suitable for small family workshops. Although the ring die granulator has a large output, it consumes a lot of electricity.

The ring die granulator also has the characteristics of good granulation shape and high density (1-1.3%).

By comparing two different pellet granulator machine, we can know the difference between them and their features. When buying a pellet mill, consider all factors limiting production to find the right equipment.