| Price | 10000-60000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Full Containers |

| Guarantee | 1 Year |

| Shipping | By Sea |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Product Overview

| Production Output | 0.15-5 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley, soybean, oil seed meal, leaf, fish meal, bone meal, etc |

| Type | dry type and wet type |

| Final Pellet Size | 0.9-10 mm |

| Application | floating pellets |

| Used For | catfish feed production |

Introduction of Catfish Feed Plant

Catfish farming is becoming a more and more popular and growing business around the world. However, catfish feed costs can be a significant challenge for catfish farmers. These costs can consume a large part of your profits. The price of commercial feed can also vary and you cannot control the quality and nutrition of commercial feed.

A catfish feed production line can offer you a practical solution. It can give you full control over feed cost and you can make different aqua fish feed. It also helps ensure the quality of the food you manufacture.

We will explain the essential machinery involved and the step-by-step catfish feed production process. Finally, we will provide practical advice on how to select the right system for your farm.

What is a Catfish Feed Production Line?

A catfish feed production line is a complete buoyant feed making system, not just a single piece of equipment. This system can process ingredients, such as corn meal, soybean meal, and fish meal. It presses these raw materials into feed pellets with all the nutrition that catfish need. A full catfish feed processing line generally works better than buying individual machines over time.

Each aquafeed making machine in an integrated line can work smoothly with the others. This line usually needs less manual labor and can help ensure you get the same high-quality feed every time when you produce feed. This aqua fish feed production line can not only produce catfish feed, but also can make feed pellets for other aquatic.

Advantages of Catfish Feed Production Line

Setting up your own catfish feed processing plant is a huge project. But it brings many advantages to your catfish farm.

Cut Feed Costs Sharply

This is often the main reason catfish farmers choose to setup your own fish feed plant. Because buying raw ingredients in bulk is usually much cheaper than purchasing commercial feed from a feed manufacturer. Industry reports show that the commercial feed price is often 25% to 50% higher than raw ingredients.

Full Control Over Catfish Nutrition & Quality

When you make your own catfish feed, you can control exactly what ingredients and nutrition you put in the feed. You can select high quality ingredients and create special feed recipes. Young catfish fry and fingerlings require a high-protein starter feed, typically 35-45% protein, for rapid development. As they mature into the grower stage, their protein requirement decreases to around 28-32%.

This allows you to give your catfish the precise pellet size food they need as they grow. Young fish need small crumbles or pellets, often 2-3 mm in diameter. Larger, growing catfish are more efficient with 5-8 mm fish feed pellet.

Reduce Feed Waste & Improve Water Quality

Catfish can eat more efficiently with high quality pellets. This means less feed is wasted. This can help keep your water cleaner, which is very important for healthy fish.

Floating vs. Sinking Feed: Which is Best for Catfish?

When you decide to produce your own feed pellets, you have to confirm to produce floating or sinking feed for your catfish.

Floating Feed

You can use floating fish pellet machine for making floating pelleted feed. The machine puffs the feed mixture under high heating temperature (about 130-150℃) and pressure. The process makes the pellets to expand and become light enough to float on the water.

Advantages: You can visually monitor the feed consumption of the catfish. This helps you adjust feeding amounts and avoid overfeeding. You can remove the uneaten floating pellets from the water easily which makes water much cleaner.

Sinking Feed

If you want to make sinking type feed, you need a sinking fish feed machine. Sinking pellets are denser and sink to the bottom of the water.

Advantages: Sinking feed is better for catfish, because they are bottom feeders and can eat naturally at the water bottom. This option offers significant advantages for a catfish farm.

Making the Right Choice for Your Catfish

Consider the specific kind of catfish you are raising. The type of farming system you use, such as your specific ponds or tanks, is also a key factor to consider.

Observing the natural feeding behavior of your fish is also a critical step. For many common catfish farms, floating feed offers more overall benefits.

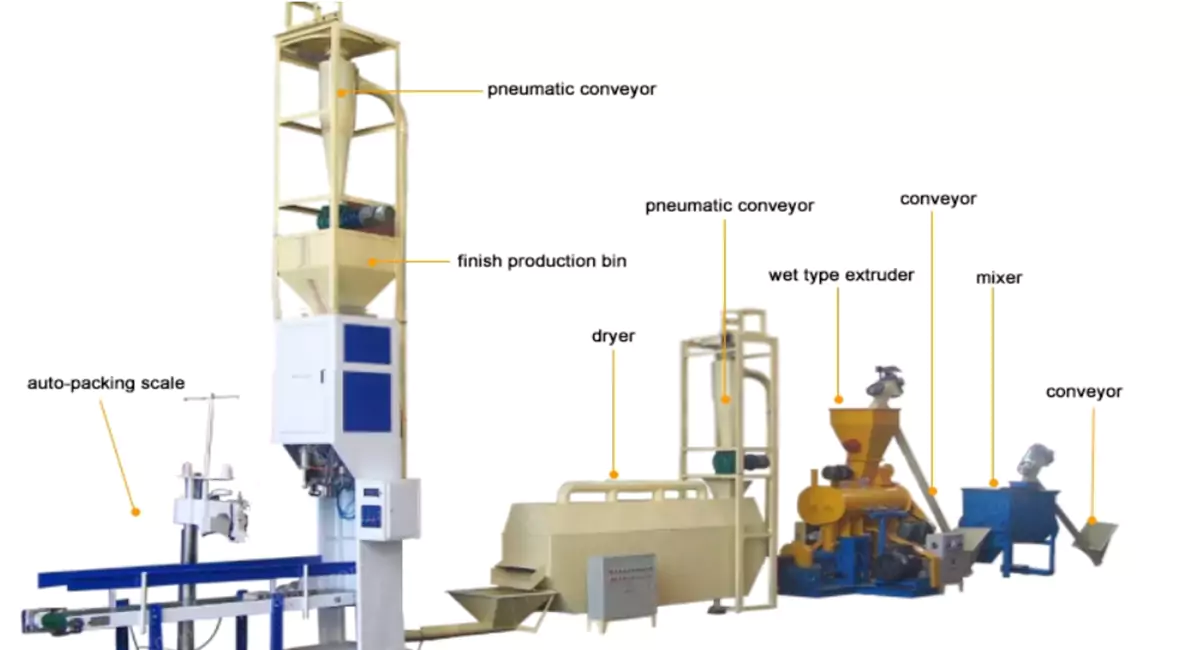

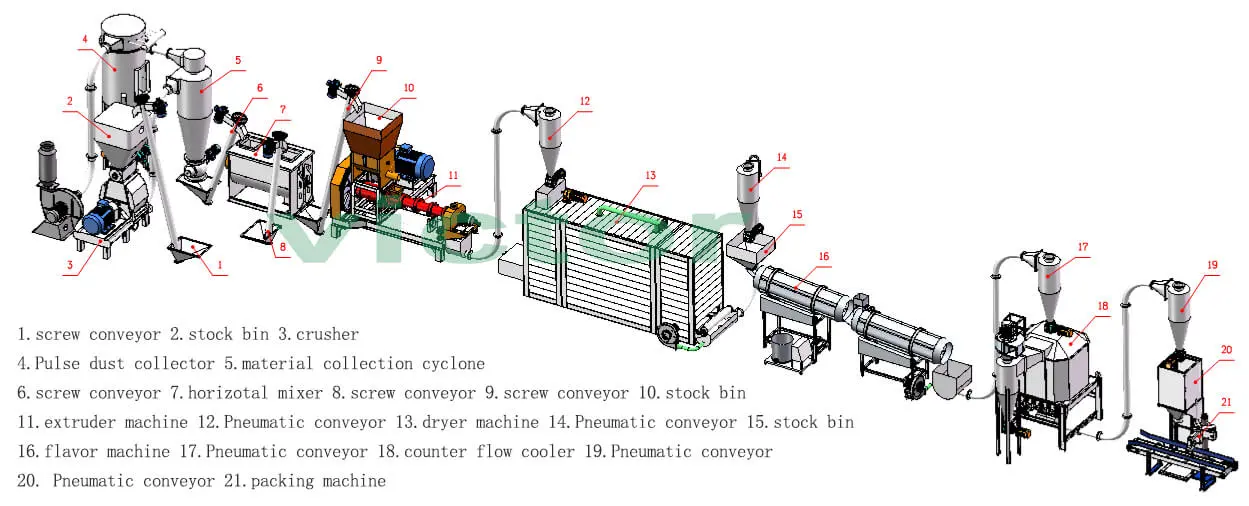

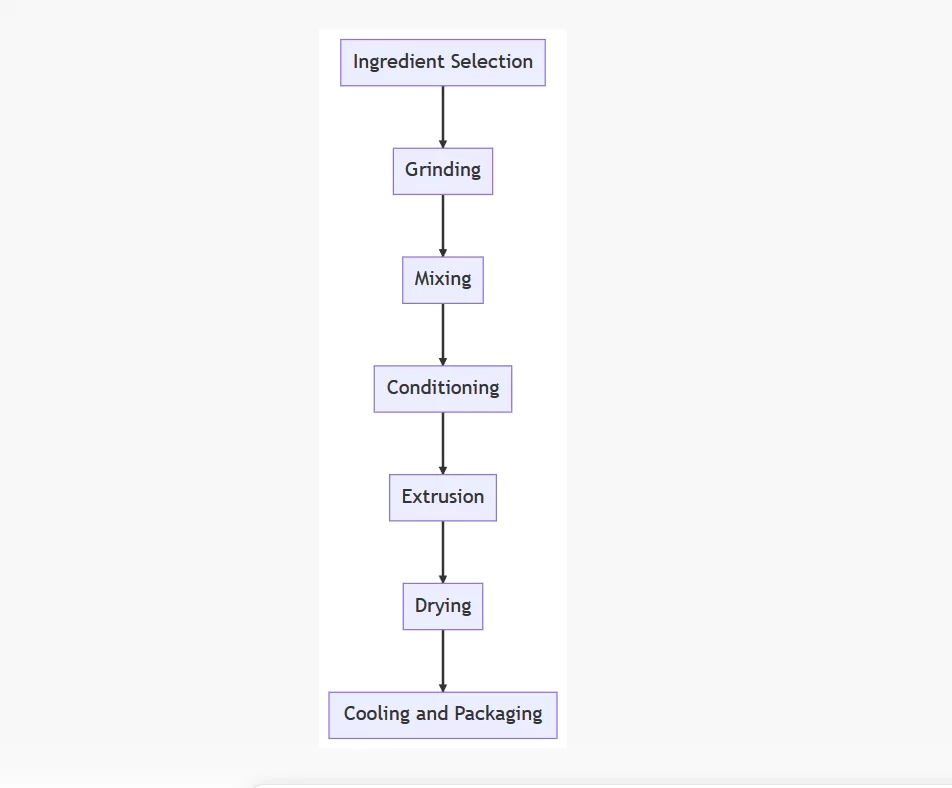

Catfish Feed Production Process & 7 Key Machines

A complete catfish feed production line follows a step-by-step process, with each machine playing a critical role to ensure consistent pellet quality, you can also check how to make catfish feed in full details:

Grinding (Grinder)

Raw catfish feed ingredients such as corn meal, soybean meal, bone meal, and fish meal are ground into fine powder. This improves mixing effect and makes nutrients easier to digest for catfish.

Mixing (Mixer)

The feed mixing machine blends ground materials thoroughly with vitamins, minerals, and additives, ensuring every pellet has balanced nutrition.

Conditioning & Shaping

The conditioned mixture is processed under high heating temperature and pressure, forming either floating or sinking pellets depending on the machine used. Fish feed extruder is usually for making floating feed, feed pellet mill is better for sinking feed.

Drying (Dryer)

Fresh pellets contain 20–25% moisture content. Hot air drying reduces this to below 10%, improving shelf life.

Cooling (Cooler)

Pellets are cooled to room temperature, preventing condensation and spoilage during storage.

Optional Coating (Oil Coater)

A thin layer of oil or fat can be sprayed on pellets to enhance energy content and palatability.

Screening & Packing (Packing Machine)

Dust and broken pellets are removed, and final products are automatically weighed and packed for storage or sale.

Choosing the Right Catfish Feed Production Line

Choosing the right catfish feed production line requires careful thought and planning. Consider these following important factors:

How Much Production You Need: Figure out how much feed you need now. Also, think about how much you might need in the future if your farm grows.

Type of Feed (Floating or Sinking?): This choice will determine the main catifsh feed making equipment you need (an extruder for floating feed or a pellet mill for sinking feed).

Automation Level: Do you want an automatic catfish feed manufacturing plant that do most of the work by themselves? More automation costs more at the start but can save labor costs later.

Space and Power: You must also consider your facility’s infrastructure. This includes having adequate space for the machinery, the correct electrical supply, and a reliable water source for steam generation.

Budget and Savings: You must determine your total budget for the initial investment. This cost should then be compared against the projected long-term operational savings on feed. The purpose of this analysis is to determine the financial viability of the production line for your farm.

Supplier Help: They should offer help with setting up the catfish feed production line. They should also offer training for you and your workers and supply available spare parts.

Conclusion

Buying a catfish feed production line is a huge investment for any fish farming. But it can be a very good one for serious catfish farmers. It gives you full control over your feed quality and helps you control your costs. It also helps you control the specific food your fish get.

With good research and careful choices, you can set up a suitable and good aquatic feed system for your farm. This system can make your farm work much better and can also help you make more money for many years.

FAQ About Catfish Feed Production Plant

1. What protein level do catfish generally need in their feed?

This changes with the age of the catfish. Young fry and fingerlings need feed with high protein. This is usually around 40-45%. As the catfish grow up, its dietary protein requirement decreases.

Grower and finisher catfish generally do well with feed that has 28-32% protein. Breeding fish also have their own special protein and fat needs.

2. Should I choose floating or sinking feed for my catfish?

Floating feed is widely used because it makes feed intake easier to monitor and water quality easier to manage. However, sinking feed can be better for bottom-feeding species or specific pond/tank systems. The best choice depends on your fish behavior and farming method, rather than one being “always better.”

3. How much does a small catfish feed production line usually cost?

Prices for these fish feed production lines can be very different. The cost depends on how much feed it makes per hour. Another key factor is whether the machine is designed to produce floating or sinking feed.

Extruders for floating feed pellet production usually cost more than for sinking feed pellet mills. The level of automation also changes the price. A very basic, small catfish feed production line for sinking feed might start at a few thousand US dollars.

A fish feed processing line for floating feed, or a more automated catfish feed pellet line, will cost more. It is always best to get price quotes from a few different suppliers before you decide.