| Price | 500-3000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Straw Pellet Machine Specifications and Features

| Production Output | 0.1-2 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | grass, hay, alfalfa, straw, cereal, corn, wheat, barley flour, soybean, oil seed meal/cake, edible leaf, fish meal, bone powder, etc |

| Type | flat die type |

| Final product size | 3-10 mm |

| Application | feed pellet producing, feed pellet industry |

| Used For | animal, poultry feed, fuel pellet production |

Electric vs Diesel Straw Pellet Machine Technical Specifications

electric straw pellet machine

| Model | Power(kw) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 3 | 50-80 | 80 |

| VTKLP-150 | 4 | 100-150 | 110 |

| VTKLP-210 | 7.5 | 200-400 | 210 |

| VTKLP-230 | 11 | 300-500 | 280 |

| VTKLP-260 | 15 | 500-700 | 300 |

| VTKLP-300 | 18.5 | 700-900 | 500 |

| VTKLP-360 | 22 | 900-1200 | 700 |

| VTKLP-400 | 30-37 | 1200-1500 | 900 |

diesel engine straw pellet machine

| Model | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 4 | 50-80 | 100 |

| VTKLP-150 | 5 | 100-150 | 150 |

| VTKLP-210 | 10 | 200-400 | 260 |

| VTKLP-230 | 15 | 300-500 | 350 |

| VTKLP-260 | 20 | 500-700 | 420 |

| VTKLP-300 | 25 | 700-900 | 650 |

| VTKLP-360 | 30 | 900-1200 | 900 |

| VTKLP-400 | 40-50 | 1200-1500 | 1200 |

What is a Straw Pellet Machine?

A straw pellet mill takes crop waste like wheat, rice, corn, and cotton stalks and turns them into dense, even pellets that can be used as fuel or bedding. It usually goes like this: reducing the size, adding moisture, making pellets, cooling, and screening. For pasture residues and dried grasses, see our grass pellet machine designed for lighter, fibrous materials.

The typical line is: size reduction → moisture conditioning (≈10–12% MC) → pelletizing → cooling → screening and packing. See our how to make straw pellets.

Straw pellets provide higher bulk density and easier handling than loose straw and can supply process heat, space heating, or CHP when matched with appropriate furnaces and emission control.

Reduce particle size to ≈3–5 mm, then adjust moisture to ≈10–12% before pelletizing. Straw types include wheat, rice, and corn straw, and cotton stalks. The ground material is conditioned for uniformity. (Pasture residues/dried grasses may suit a grass pellet setup.)

Put the conditioned straw into the pellet mill (ring-die/flat-die) to make it more compact. Add a small binder, like wheat gluten or lignin, if self-binding isn’t enough to help with PDI and fines control. After pelletizing, cool to almost room temperature, screen, and pack. (See step-by-step: moisture level of about 10–12%, die compression ratio that matches the fiber, and PDI testing.)

How Straw Pellets Contribute to Biomass Energy Solutions

Straw pellets are a renewable fuel that can take the place of fossil fuels. The impact on the lifecycle depends on how the material is collected, dried, transported, and burned.

Using straw cuts down on burning fields and landfilling, and it makes use of a cheap, widely available waste product. Some uses are for industrial heat, district heating, and making electricity with the right boilers.

Biomass is almost carbon-neutral at the point of use because the CO₂ released during combustion is about the same as the CO₂ absorbed during growth. The actual net effect depends on the supply chain and the controls on emissions.

This forms a closed carbon loop when systems are well managed, unlike fossil fuels that add geologic carbon to the atmosphere.

Top 5 Benefits of Using a Straw Pellet Machine in Sustainable Energy Production

1. Cost-Efficient Energy Production

Straw Pellet Machine Price vs. Energy Savings

The cost of capital expenditures (capex) changes based on the type of dryer, the amount of capacity, the materials used, and the level of automation. Instead of flat savings claims, use an equal-energy (€/GJ) model.

This means comparing the cost of making pellets per GJ (raw straw + drying energy + electricity + labor + maintenance + depreciation + logistics) to the cost of coal, oil, or wood pellets delivered per GJ at the actual boiler efficiency.

Affordable Raw Material for Biomass Production

Straw is a common by-product that usually costs less than forest residues. If you can collect and store straw, a straw pellet line can lower your fuel OPEX.

2. Reduces Agricultural Waste and Improves Waste Management

Converting Straw Waste into High-Quality Biomass Fuel

Pelletizing takes leftover materials from the field after harvest and turns them into usable fuel instead of burning them in the open air. This lowers the amount of particles that are released into the air compared to uncontrolled burning.

Environmental Benefits of Reducing Field Burning

Not burning fields also protects the organic matter in the soil and keeps nutrients in the soil. Pelletizing lowers the pressure on landfills and makes better use of resources.

3. High-Quality Fuel with Low Emissions

PDI shows how durable something is mechanically. Higher PDI lowers fines during feeding and transport, which helps with consistent metering and combustion. The design and controls of the furnace, not the pelletizer, affect combustion emissions.

4. Promotes Sustainability in the Energy Sector

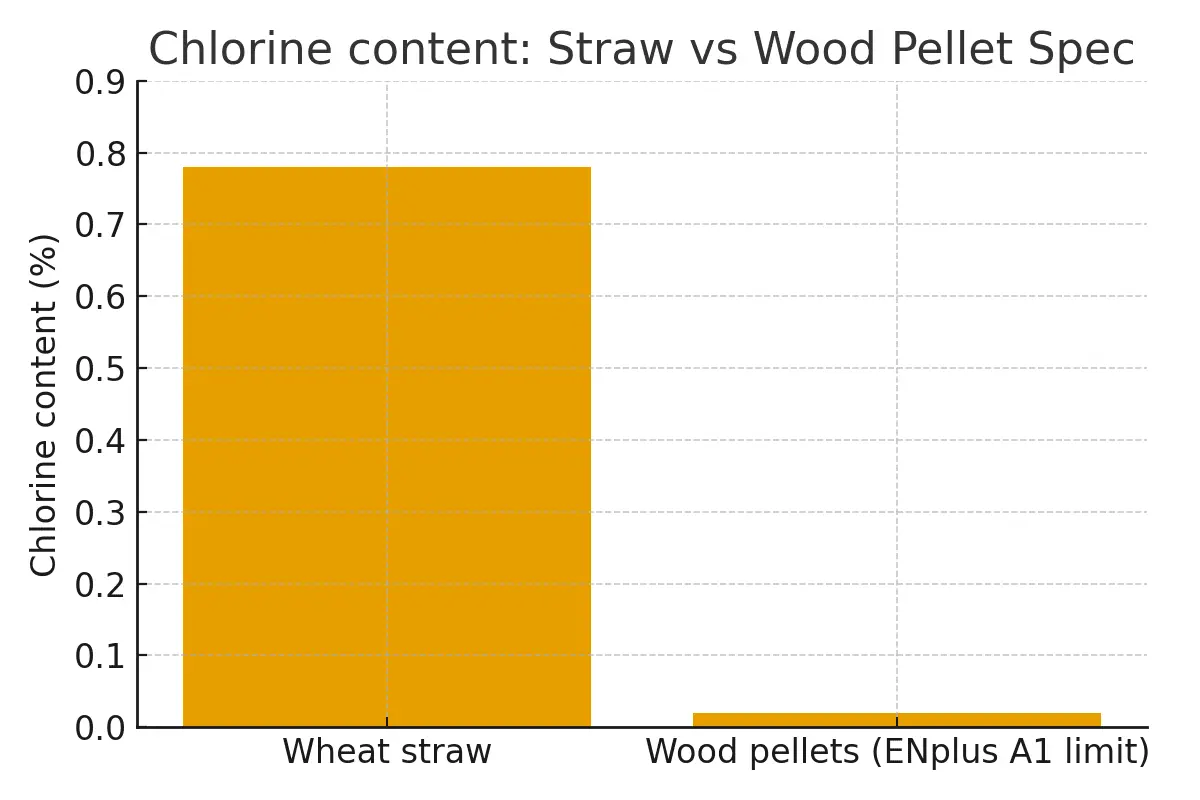

When used instead of wood pellets, straw pellets can lower carbon emissions over their entire life cycle and put less stress on forests. To reduce the chances of slagging and fouling, make sure that the fuel properties match the furnace designs.

5. Versatility and Multi-Use Applications

Straw Pellet Production for Farms and Animal Bedding

In addition to being a fuel, straw pellets make good bedding for animals because they absorb moisture well and take up less space when stored. Using one product for both heat and bedding can make things easier to manage.

Key benefits of straw pelletizing for farms:

Benefits for farms include lower fuel costs (depending on the site), less waste going to burning or landfills, and easier storage and handling.

FAQ About Straw Pellet Machine

1. What is the price of a straw pellet machine, and how does it compare to other biomass pellet mills?

The price depends on the type of dryer (airflow or rotary), the amount of material it can hold (0.5–1 t/h vs. 2–3 t/h), the power it needs (main motor + feeder + conditioner), whether it is automated, and any extras it needs (cyclones, dust filters, conveyors). Instead of asking for broad ranges, ask for quotes by configuration list.

Wood pellet mills made for high-density wood are often built to last longer than other types. This can sometimes mean that the equipment costs more at first.

2. How do I optimize energy efficiency in straw pellet production?

Pay attention to four things: (1) controlling the moisture in the feed; (2) matching the die compression ratio to the fiber; (3) cooling and screening to cut down on fines losses; and (4) drying heat recovery (for example, using multi-pass dryers or waste heat).

3. Can a straw pellet machine handle high moisture straw?

For >20% MC, pre‑dry to ≈10–12% MC before pelletizing (rotary or airflow dryers). Monitor inlet/outlet MC to avoid over‑drying and brittle pellets.

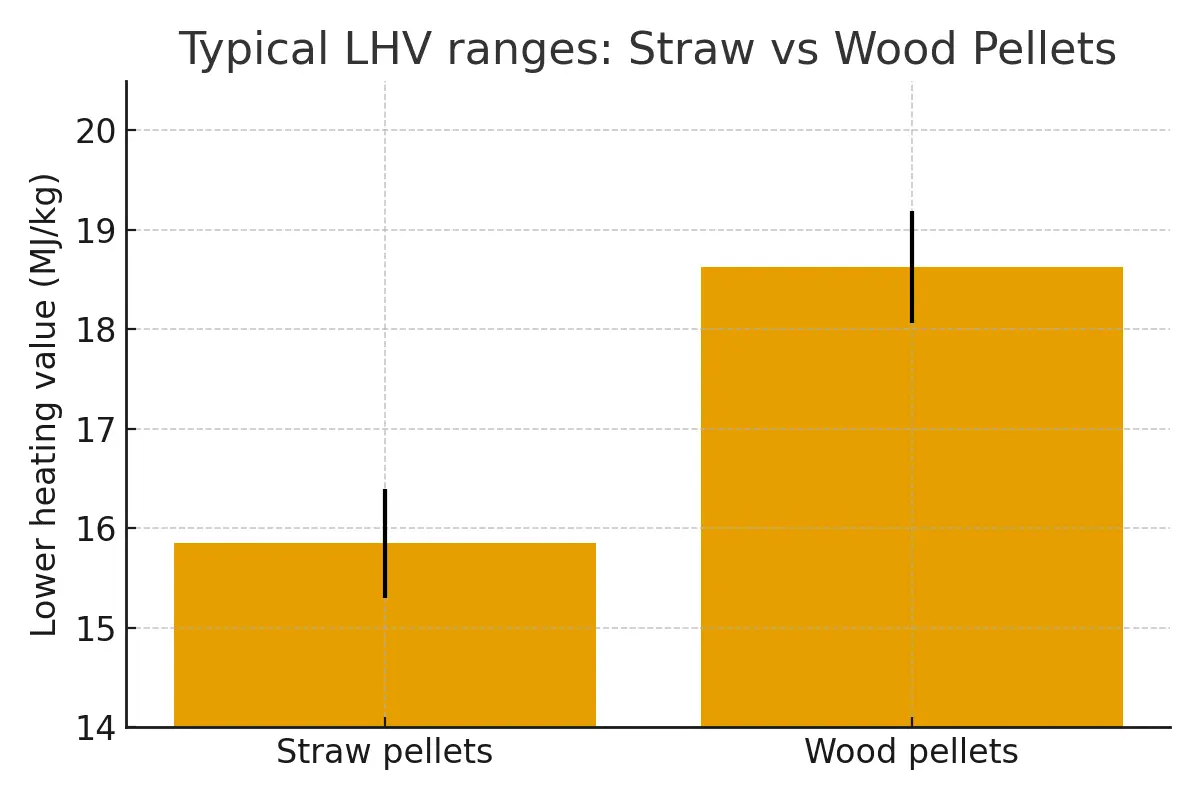

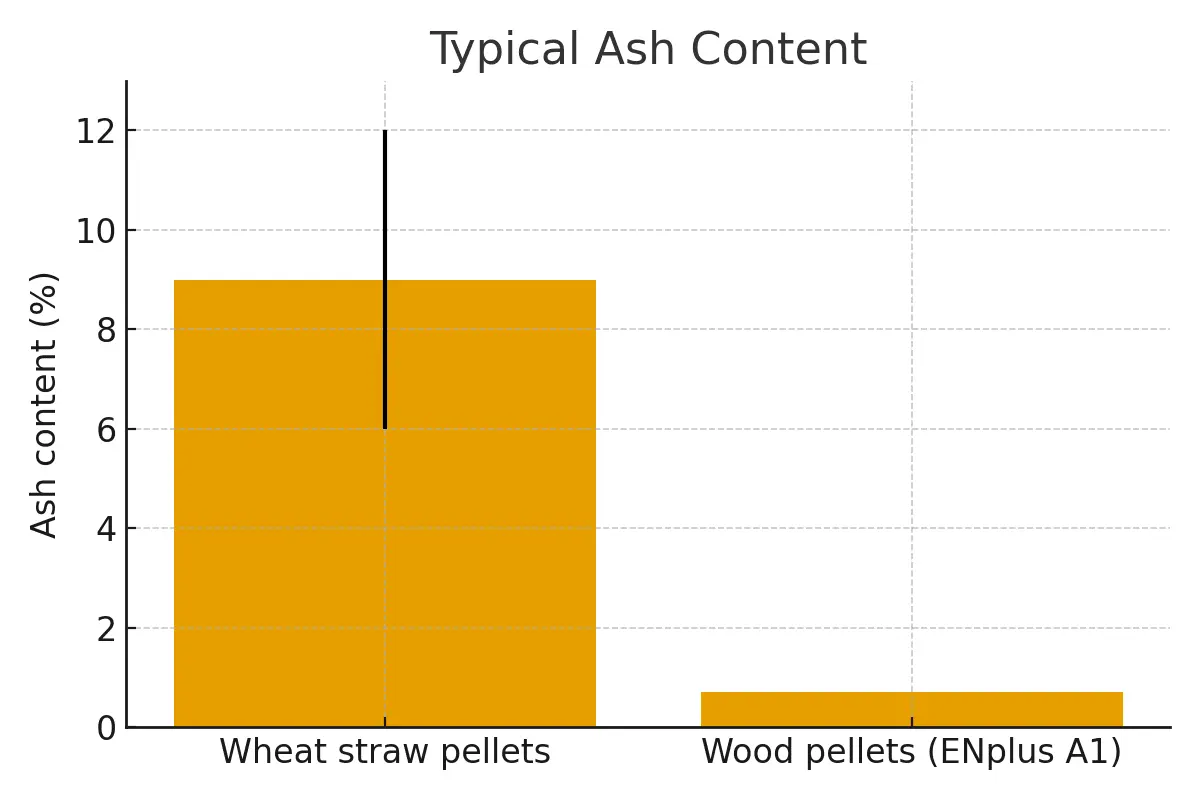

4. What are the main differences between straw pellets and wood pellets?

Usually, they have a higher LHV and less ash, which makes them easier for small stoves. Straw has a higher risk of ash and alkali (K/Cl) and slagging, so it needs the right boilers and ash management. It is often cheaper to use straw as fuel when it is easy to find.

5. How does straw pellet quality affect its use in energy production?

Higher PDI and controlled MC make it easier to handle, feed, and keep the fire going. Check each batch or lot with PDI, fines %, bulk density, and residual moisture tests.