| Price | 23000-250000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Poultry Feed Line: 0.5-15T/H Capacity

| Production Output | 0.5-15 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal, leaf, fish meal, grass meal, hay meal, etc |

| Type | flat die type and ring die type |

| Final Pellet Size | 2-10 mm |

| Application | feed production |

| Used For | chicken food production, bird food production |

Automated Pelletizing: 4mm poultry Feed production video

Introduction of poultry feed production line

You already know that feed is the most expensive thing you buy if you raise chickens. It can be a real pain. You worry about the high price and sometimes the poor quality of the feed you buy.

A poultry feed production line is a system that was made to solve this problem. You can control what your birds eat with this smart investment for your farm. You can make the best food for them, which will help them stay healthy and save you a lot of money over time.

small poultry feed production line

small poultry feed production line

What is a Poultry Feed Production Line?

A poultry feed production line is more than just one machine, so it’s important to know that. You should see it as a whole system that works together. There are a lot of machines that work together in a certain order. They do everything, from grinding your corn into flour to putting the finished pellets in bags.

The Real Advantages of Poultry Feed Production Line

Having your own line for making poultry feed is very helpful for your poultry business.

Cost Savings Through Bulk Ingredient Purchasing

This gives you a big edge when it comes to money. You can buy a lot of your main ingredients, like corn and soybean meal. This helps you get much better prices at wholesale. It also keeps your farm safe from the price swings that happen a lot with bagged commercial feed.

Customized Nutrition for Optimal Animal Performance

This lets you make the right fuel for the job. To build muscle quickly, a broiler needs a feed that is high in protein. To lay strong, high-quality eggs, your layers need more calcium. You can make a perfect, new recipe for each group with your own line. This means that your birds will be healthier and you’ll get better results, like faster growth or more eggs in the basket.

Total Control Over Feed Quality and Safety

You are in charge of everything when you make your own poultry feed. You know exactly what each pellet is made of. This makes you feel better. You can be sure that there are no cheap fillers or other things you don’t want. This complete control makes birds healthier and more productive right away.

Gain True Independence for Your Farm

Your farm is at risk if you depend on outside suppliers. A truck that is late or a lack of stock can cause big problems. It makes you feel stressed out for no reason. This risk goes away when you have your own plant. You really get feed security. This will make you feel better. You know that your flock will always get the right feed at the right time.

Large poultry food production line

Large poultry food production line

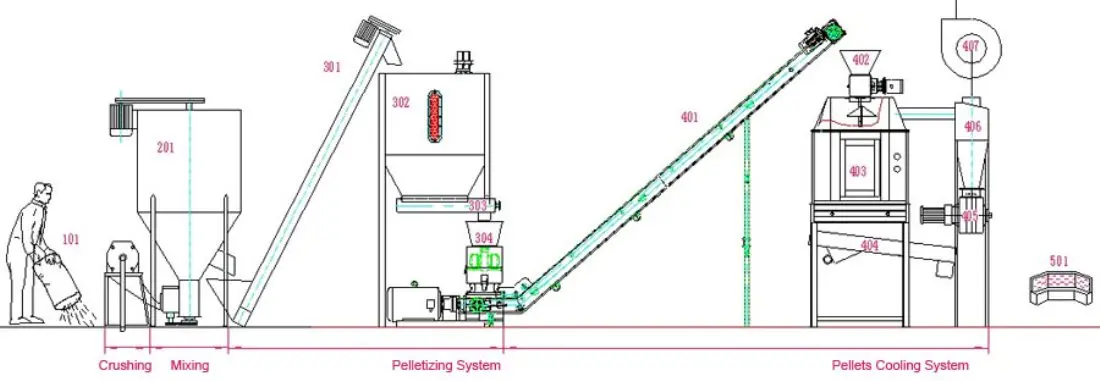

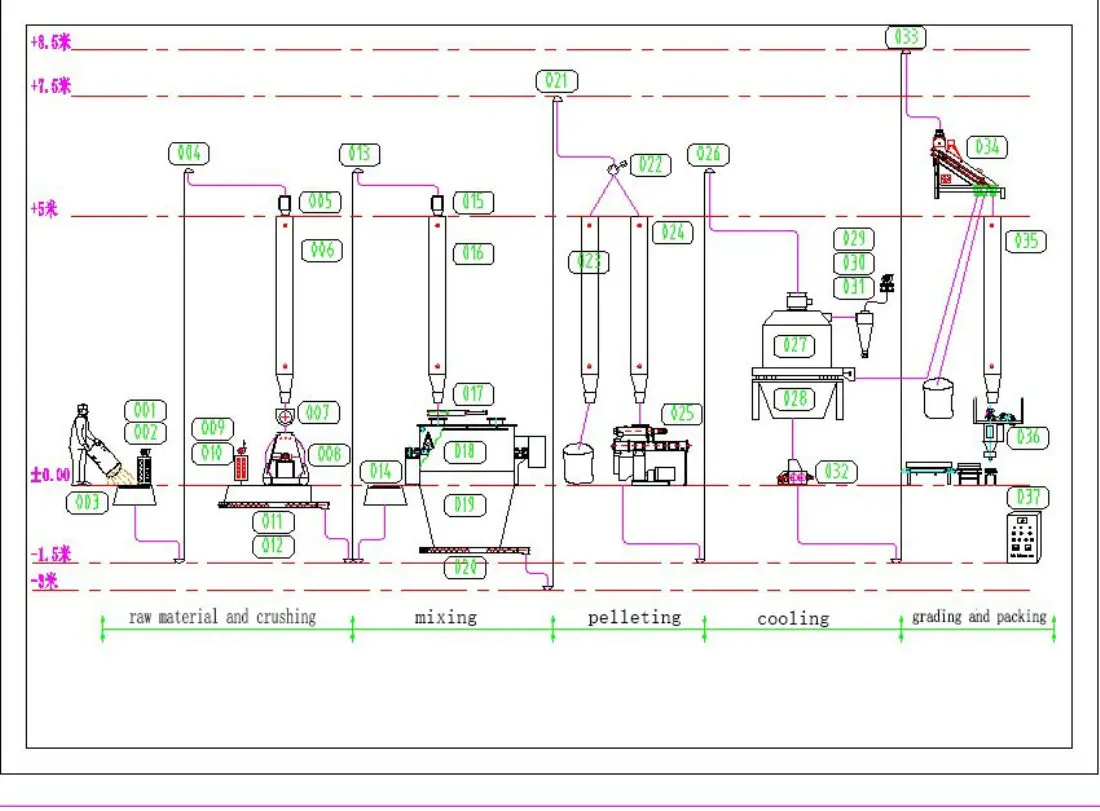

Key Machinery and Production process

A modern poultry feed production line is set up in key sections. Each section has a special machine that performs one important step in the process.

Raw Material Handling and Storage

The first step in the whole process is getting your raw materials. If you start with bad ingredients, you can’t make good feed. This first step is all about getting your grain and keeping it safe.

There are usually big silos in this area. These tall bins keep your corn and soy safe from bad weather and bugs. It also has conveyor belts. These machines move your ingredients to the next step in the production line without any problems.

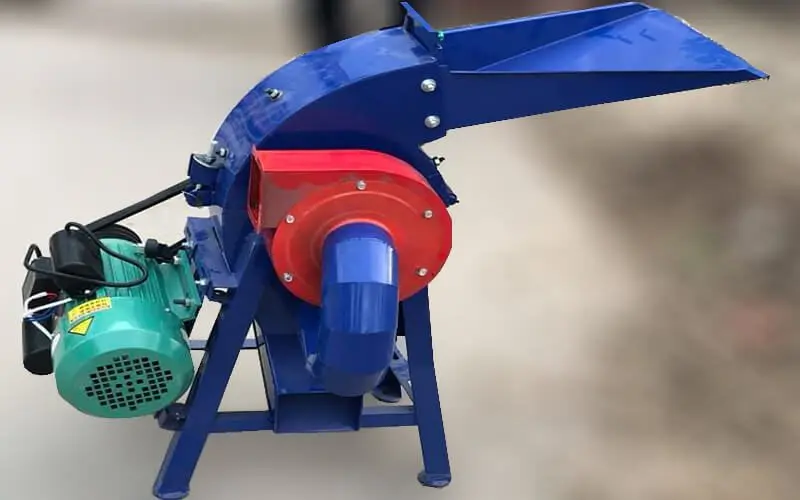

Importance of Feed Crushing for Digestibility

The poultry feed crusher has one key job. It grinds your raw ingredients into a fine, even powder. This step is vital for your flock’s health. Chickens, especially young ones, must have this fine texture to properly digest their food.

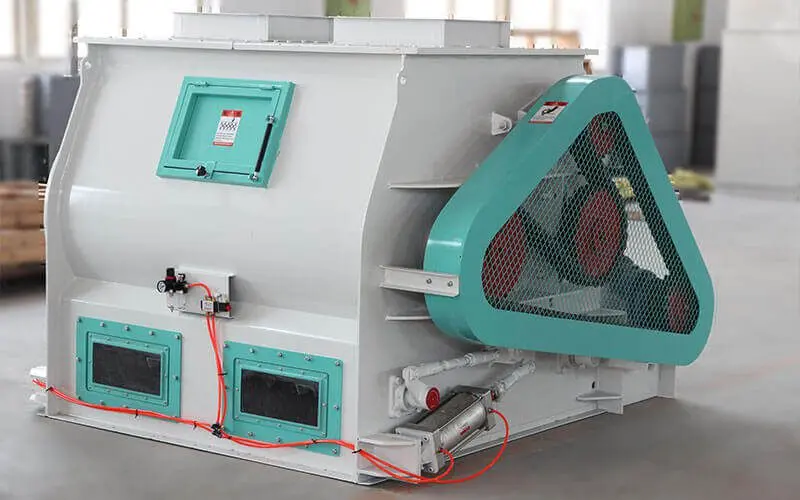

The Mixing Stage: Creating a Balanced Meal

After grinding, the different powders are moved to a large poultry feed mixer. This step is vital. Its job is to blend all the ingredients perfectly. This makes sure that all of the important micro-ingredients, such as vitamins and minerals, are spread out evenly throughout the whole batch. A perfect mix makes sure that every bird gets the right amount of nutrition in every bite.

The Cooking Process: Better Digestion and Safety

This next step is the key to making high-quality feed. The steam conditioner cooks the feed mash slowly. It adds heat and moisture with hot steam. This cooking process is very important. It breaks down the grain’s starches. This makes the food much easier for your chickens to eat. It also kills bad bacteria, which is good for the health of your flock.

The Heart of the Line: The Pellet Mill

The poultry feed pellet mill is the true heart of your production line. The warm, conditioned mash goes here. Powerful rollers push this mash through a special metal plate called a die inside the mill. This process, which uses a lot of pressure, turns the mash into the hard, dense pellets that your flock needs.

Pellet Cooling for Storage Stability

The Pellet Cooler (Counterflow Cooler): Pellets come out of the pellet mill very hot and a little soft. A cooler uses air to cool them down and get rid of extra moisture. This step is what makes the pellets hard and safe to store.

The Role of the Crumbler in Starter Feed Preparation

A crumbler is a must-have tool if you are raising chicks from the very beginning. Newly hatched broilers and layers often have trouble eating full-sized pellets because their beaks are too small for them. The crumbler fixes this by gently breaking the pellets into smaller, even pieces that are easy for young birds to eat. This makes sure they get the right food from the start.

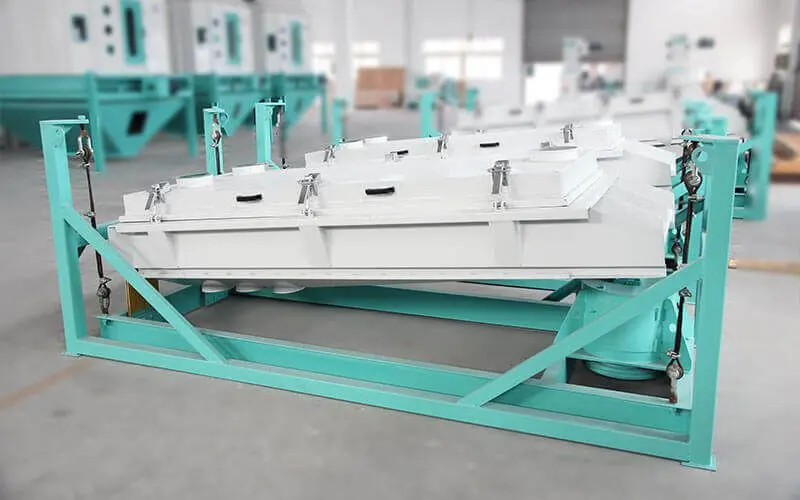

The Screening Section (Rotary Sifter):

The feed goes through a sifter after it has cooled and broken up. This step gets rid of dust-like particles and makes sure that every pellet is the right size. You get consistent, high-quality feed ready for packaging.

The Bagging & Storage Section:

Automatic packing machines fill the bags in the last step. These machines can automatically weigh and pack the food when it’s done. Then they seal it up automatically so it can be sold or stored.

poultry feed production process

for small capacity

for large capacity

poultry feed manufacturing process flow chart

for small production capacity

for large production capacity

Planning Your Poultry Feed Production line

Starting your own poultry feed production line is a big step forward for your poultry business. It will take a lot of work, but if you plan it out well, it could be the best thing you ever do with your money.

Start with an Honest Look at Your Production Needs

The first question has nothing to do with machines; it has to do with your birds. How many are you giving food to today? More importantly, what do you think your flock size will be in the next three to five years?

This number is the most important part of your plan. It tells you how many tons per hour your plant needs to be able to make. It’s easy to want to buy a bigger plant than you need, but spending too much can tie up your money. Be realistic and plan for growth that is smart and easy to handle.

Your Raw Material Supply

Your supply chain is the most important part of your feed business. Can you always get good quality corn, soybean meal, and other important ingredients? And can you afford to buy them?

Plan Your Physical Space and Utilities

A feed plant needs a good place to live. You’ll need enough room for the machines themselves, as well as separate, safe places to keep your raw materials and your finished, bagged feed.

But it’s more than just a roof. You need a reliable power source, and for most big plants, that means a three-phase connection. To run the conditioner, which is an important part of making high-quality, digestible pellets, you’ll also need a steam boiler.

Choose Your Equipment Partner Wisely

The person you buy your machinery from is just as important as the machinery itself. Don’t just buy equipment from any old store; look for a reliable supplier with a lot of experience building poultry feed plants.

Ask them the tough questions. How good is their service after the sale? Is it easy and quick to get spare parts? Keep in mind that if a machine breaks down, your whole feeding program stops. It’s not up for debate that a good partner is necessary.

Conclusion

Choosing to set up a poultry feed production line is a serious business decision. It’s a big step. But it’s also the single best way to take charge of the two factors that control your farm’s profit: your feed costs and your flock’s nutrition. With smart planning and the right equipment, your own feed line can become the solid foundation of a successful, growing, and truly independent poultry business.