| Price | 3000-80000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

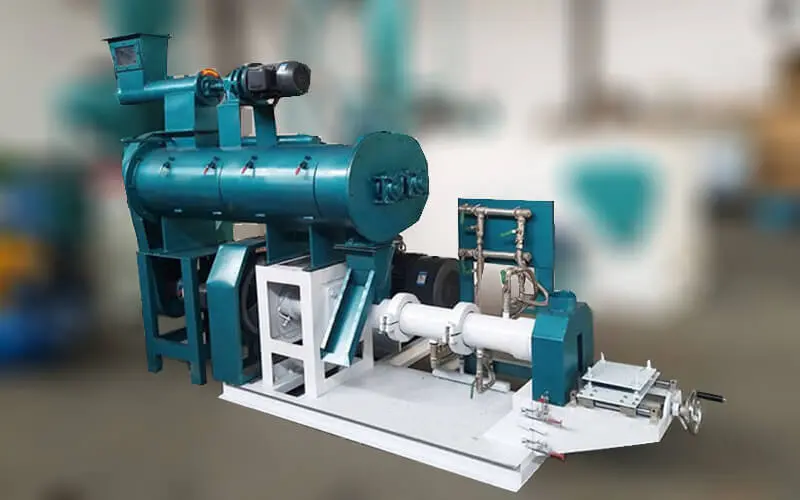

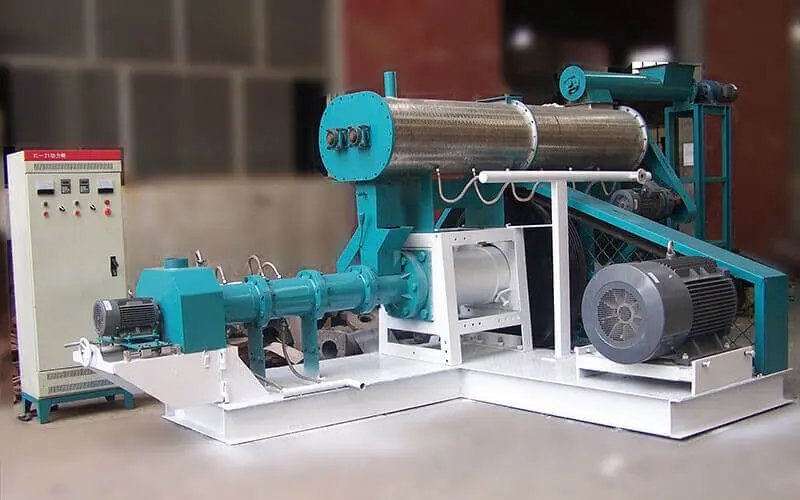

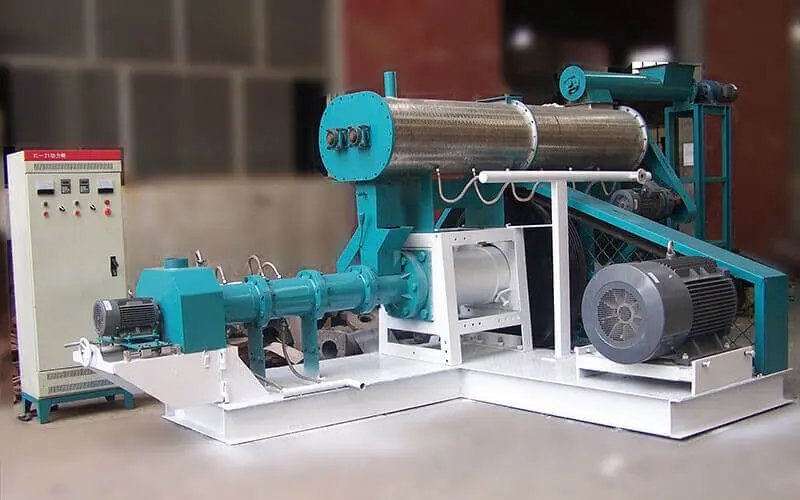

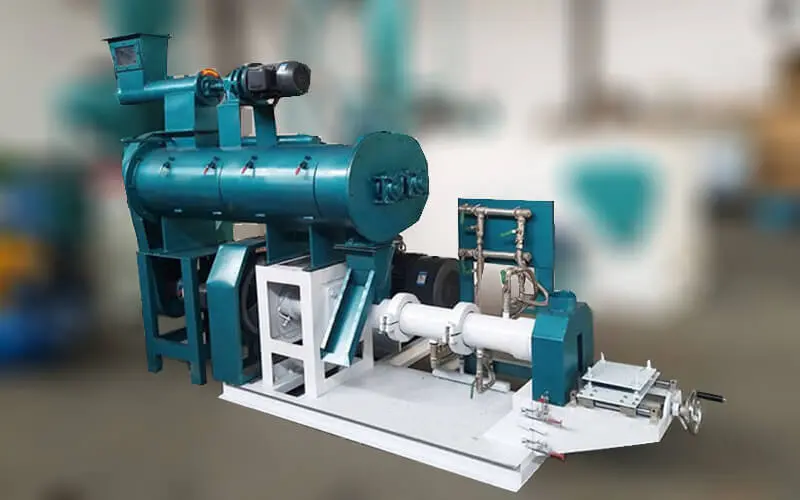

Floating Fish Feed Extruder Specifications and Features

| Production Output | 0.1-5 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal/cake, edible leaf, fish meal, bone powder, etc |

| Type | wet type feed extruder machine |

| Final product size | 0.9-15 mm |

| Application | feed pellet producing |

| Used For | floating fish feed production |

Floating Aquatic Feed Extruder Technical Specifications by Model

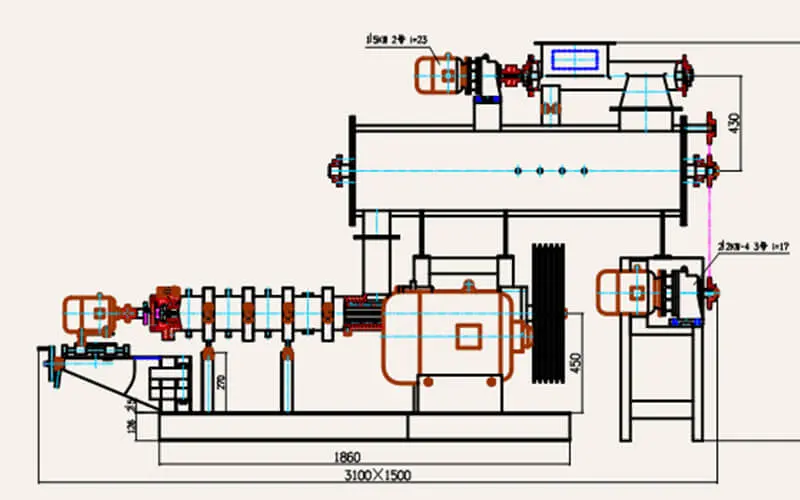

electric floating fish feed extruder

| Model | Capacity(kg) | Main Power(kw) | Feeding Power(kw) | Cutting Power(kw) | Screw Diameter(mm) | Conditioning power(kw) |

| VTSP-60 | 150-200 | 15 | 0.4 | 0.4 | 60 | 0.37 |

| VTSP-70 | 300-400 | 18.5 | 0.75 | 0.4 | 70 | 1.1 |

| VTSP-80 | 400-500 | 22 | 0.75 | 1.5 | 80 | 1.5 |

| VTSP-90 | 500-600 | 37 | 1.1 | 2.2 | 90 | 2.2 |

| VTSP-120 | 700-800 | 55 | 1.1 | 2.2 | 120 | 2.2 |

| VTSP-135 | 1000-1200 | 75 | 1.5 | 3.0 | 135 | 3.0 |

| VTSP-160 | 1500-2000 | 90 | 2.2 | 3.0 | 160 | 4.0 |

| VTSP-200 | 3000-5000 | 132 | 2.2 | 4.0 | 200 | 5.0 |

How Floating Feed Extruder Enhances Aquatic Nutrition (Video Guide)

Introduction of floating fish feed extruder

As a fish farmer, you know the feeling. You toss a scoop of feed into the pond, and it vanishes into the murky water. You’re left standing there asking yourself the same old question: “Is that feed growing my fish, or is it just feeding the mud at the bottom?”

This uncertainty costs you money in wasted feed and can lead to poor growth in your fish. The floating fish feed extruder machine is the specific technology designed to solve this exact problem. It doesn’t just make pellets; it cooks and expands them, creating a buoyant feed that stays on the surface where you can see it.

What is a Floating Fish Feed Extruder?

Think of a floating fish feed extruder machine as a specialized, high-pressure cooker that also shapes the food at the same time. It takes a finely ground and mixed feed mash. It then cooks it with intense heat and pressure in just a few seconds. Finally, it forms the cooked dough into the familiar pellet shapes as it exits the machine.

Its core purpose is to create a light, porous, and highly digestible pellet that floats on water for an extended period. This makes it the ideal machine for most modern aquaculture operations.

What is the Advantages of Extruded Floating Feed

Using feed made from a proper fish feed extruder machine is a game-changer for your farm. It’s not just a small improvement; it fundamentally changes how you manage your feeding, your water quality, and your bottom line. Here are the powerful advantages you’ll see.

Stop Guessing, Start Seeing: The Power of Visual Feeding

This is the benefit you’ll appreciate every single day. Because the pellets float, you can finally see your fish eat. This simple change takes all the guesswork out of feeding. You can tell immediately if they’re hungry or if you’re giving them too much. This helps you prevent both wasteful overfeeding and the slow growth that comes from underfeeding. You get to adjust their ration based on their actual appetite.

Less Waste in the Water, More Money in Your Pocket

Floating pellets don’t get lost in the mud at the bottom of the pond. This means nearly all the feed you produce is eaten by your fish. The impact is huge. You save a lot of money on wasted ingredients. It also protects your water quality. Uneaten, decomposing feed is a major cause of pollution in a pond, and this technology helps solve that problem.

The Science of Cooking: Better Digestion, Faster Growth

The high heat inside the extruder cooks the starches in the feed. This process, called starch gelatinization, makes the carbohydrates much easier for a fish’s system to digest and absorb. Here in Alaska, where we need to make the most of every day of our short growing season, this is critical. Better digestion often leads to a much-improved Feed Conversion Ratio (FCR) and faster, healthier growth across your entire stock.

A Cleaner, Safer Meal for Your Fish

That same intense heat and pressure inside the machine also act as a sterilizer. It kills most of the harmful bacteria that can be found in raw ingredients. The result is a cleaner, safer, and more hygienic feed for your fish. This is a simple but powerful way to reduce the risk of disease on your farm.

How an Fish Feed Extruder Makes Feed Float

The way an extruder makes feed float is a brilliant piece of engineering. It’s a simple, rugged process, which is why these machines are so reliable in demanding places like Alaska. It all happens in a few powerful seconds.

The Heart of the Machine: The Screw and Barrel

The two main parts are the barrel, which is the heavy outer wall, and the screw, which is a powerful auger that spins inside it. The screw is designed to grab your feed mash and force it forward with incredible power.

The Squeeze: Creating Heat and Pressure

As the screw forces the mash down the narrow barrel, it creates immense pressure and friction. This friction is so intense that it flash-cooks the feed in seconds, heating it to temperatures of 120-150°C. This ensures the feed is fully cooked and sterilized.

The “Pop”: How Pellets Learn to Float

This is the most important part of the whole process. After being squeezed under intense pressure, the super-heated mash is pushed out through a small hole in a die. The instant it hits the open air, the pressure drops dramatically. This causes the trapped moisture inside the feed to instantly turn to steam, puffing the pellet up from the inside out. It’s a lot like how a kernel of corn pops. This rapid expansion is what creates the light, airy structure that makes the pellet float.

Extruder vs. Pellet Mill: What’s the Real Difference?

It is very important to know that these are two different machines that do different jobs. It is better for you to know the difference of single screw vs twin screw extrusion.

The Core Technology: Cooking vs. Compressing

An extruder cooks and expands the feed to make it light and buoyant. A pellet mill simply compresses the feed with pressure to make it dense.

The Final Product: Floating vs. Sinking

An extruder machine, that is floating pellet machine, is required to make true floating feed. A sinking fish feed machine is used to make sinking feed.

Cost and Complexity

Extruders are more complex machines. They represent a higher initial investment compared to standard pellet mills.

How to Choose the Right fish Feed Extruder Machine

When you’re ready to invest in an extruder, you need to look past the sales brochure and ask the tough questions. A good machine is the heart of a profitable fish farm. Here are the key details I always tell farmers to focus on before they buy.

Look at the Steel: Screw and Barrel Quality

The screw and the barrel are the parts that do all the hard work. They are under constant, intense pressure and heat. You must insist on parts made from high-quality, wear-resistant alloy steel. Cheaper metals will wear down fast, leading to poor performance and expensive repairs. This is the true measure of a machine’s build quality.

Ask About Real-World Capacity

Don’t be fooled by a simple capacity number. A machine’s output for easy-to-process corn is very different from its output for a real-world fish feed formula that’s rich in proteins and fats. Ask the supplier for the capacity rating based on a typical fish feed recipe. This is a pro question that shows you’re a serious buyer.

Understand the Heating System

Find out how the machine controls its cooking temperature. Does it rely only on the heat created by friction, or does it have an external heating system? An external system gives you much more precise control over the cooking process. This leads to a more consistent, higher-quality pellet.

Think About Future Maintenance

You will need to change the die to make different pellet sizes, and you’ll need to clean the screw. Ask the supplier how easy it is to do these jobs. A machine that is designed for simple maintenance is one that will be better cared for, which means it will last longer and perform better.

Confirm Your Power and Support System

Before you do anything else, confirm you have the necessary three-phase power supply to run the machine’s motor. Most importantly, talk about after-sales support. Here in Alaska, being able to get spare parts and technical advice quickly is critical. A cheap machine with no support is a bad deal, no matter the price.

Three Rules for Mastering Your Extruder

Owning an extruder is one thing; mastering it is another. The machine’s manual will give you the basics, but here are three hard-won lessons from the field that will save you a lot of time, money, and frustration.

1. The Golden Rule: Your Grinder is Your Extruder’s Best Friend

Remember this: you cannot expect good results from your extruder if you feed it poor-quality material. The extruder needs a very fine, consistent powder to work its magic. You must have a good-quality grinder as a partner to your extruder. Putting coarsely ground ingredients into the machine is the number one cause of clogs and poor-quality pellets.

2. The Art of the Process: Getting the Moisture Right

The extrusion process is very sensitive to moisture. This is the part of the process that takes a little practice to get right. If your starting mash is too dry, the ingredients won’t cook or expand properly, and you’ll get a dense, useless pellet. If it’s too wet, you’ll end up with a mushy, poorly formed product. Mastering that perfect moisture level is the true art of making great feed. The best moisture is 20%-25%.

3. The Final Step That Saves Your Batch: Proper Drying

Your pellets will come out of the extruder hot, steamy, and very moist. A good dryer is not an optional extra; it is essential. You must dry the pellets down to a safe moisture level, which is usually below 10%. This is the critical step that prevents mold and gives your feed a good, long shelf life. With our short Alaskan summer in full swing, properly drying and storing your feed now is key to being ready for the long winter ahead.

FAQ About Floating Fish Feed Extruder Machine

1. What is the main machine that makes fish feed float?

A: The machine that makes feed float is called a floating fish feed extruder. The best way to think of it is as a high-speed pressure cooker. It uses intense heat and pressure to instantly cook the feed mixture. This process traps tiny air pockets inside each pellet, which is what makes them float.

2. What’s the difference between a single-screw and a twin-screw extruder?

A: A single-screw extruder is simpler and more common for making basic floating feeds. A twin-screw extruder has two intermeshing screws. It offers much more control over the mixing and cooking process. It is more expensive but is better for making very high-fat feeds, very small micro-pellets, or feeds with a high percentage of fresh ingredients.

3. Do I need a steam boiler with my floating fish feed extruder?

A: Usually wet type machine need steam boiler, while dry type machine does not need. This extruder is wet type fish feed extruder, so it needs steam boiler. A steam boiler can supply steam to the conditioner right before the extruder. This pre-conditions the feed mash with heat and moisture. This leads to a much better cooking process inside the extruder and higher quality pellets.

4. Why do extruded floating pellets sometimes cost more than sinking pellets?

A: That’s a fair question. The simple answer is that making feed float is a more advanced process. The process also uses more energy. That flash-cooking action takes a lot of power, which is a significant cost, especially with energy prices here in Alaska. This higher cost of manufacturing is what you see reflected in the final price of a bag of high-quality floating feed.

5. Can a floating fish feed extruder machine also make sinking feed?

A: Yes, many modern extruders are versatile. By changing the machine’s settings (like reducing the temperature and pressure), adjusting the recipe (for example, by using less starch and more protein or fat), and changing the die design, you can often make the machine produce a denser, slow-sinking or sinking pellet.