| Price | 20000-160000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Animal Feed Production Line: 0.5-15T/H Capacity

| Production Output | 0.5-15 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal/cake, edible leaf, fish meal, bone powder, grass meal, hay meal, etc |

| Type | flat die type and ring die type |

| Final Pellet Size | 2-10 mm |

| Application | producing animal and poultry food pellets |

| Used For | cattle, goat/sheep, rabbit, deer, pig |

Automated Feed Production video: 10mm Livestock Feed

Starting an Animal Feed Production line

If you run a feed business or a large animal farm, you might have to deal with two things all the time: 1. the feed is getting more expensive, and 2. the quality of the feed is not always good. If you get your feed from outside sources, you might feel like you can’t control the quality.

One strong way to control the quality of the feed is to buy your own animal feed production line. It’s not just about making your own feed pellets; it’s also about being able to handle your biggest expense and make sure the feed is of good quality.

small Animal feed production plant

small animal feed production plant

What is an Animal Feed Production line, Really?

A dedicated industrial facility makes animal feed. It has a full set of machines that work together to make animal feed on a large scale and in a consistent way.

This is a system for making things on a medium to large scale, not just one machine in the backyard. It is a big improvement that focuses on quality control, volume, and efficiency.

Large animal feed production line

Large animal feed production line

The Real Advantages of Animal Feed Production lin?

Investing in your own animal feed production line offers several powerful business advantages.

Drastic Cost Control and Higher Profits

You can get your raw materials, like grains and protein meals, straight from the source at wholesale prices. This keeps you from having to pay extra for pre-bagged commercial feed.

Total Quality and Formula Control

This is a big plus. You can make exact recipes (formulations) for different kinds of animals. You can also make different foods for different stages of life. This makes sure that your animals get the right food for the best performance. You know exactly what is in the food you give your animals.

Unbeatable Freshness and Consistency

Animals like fresh feed better, and it is usually healthier for them. A production line makes sure that every batch is of the same high quality. The animals perform better and more predictably because of this consistency.

Flexibility to Serve Multiple Animals and Markets

A flexible animal feed processing plant can make feed for chickens one day and cows the next. You can do this by changing the formulas and some settings on the machine.

A New Profit Center for Your Business

An animal feed production plant lets you sell feed as well as make it for your own animals. You can sell your good feed to other farms in the area. This could lead to a new and profitable business.

Key Machinery of Animal Feed Production line

Each machine in an animal feed production plant has a vital role to play.

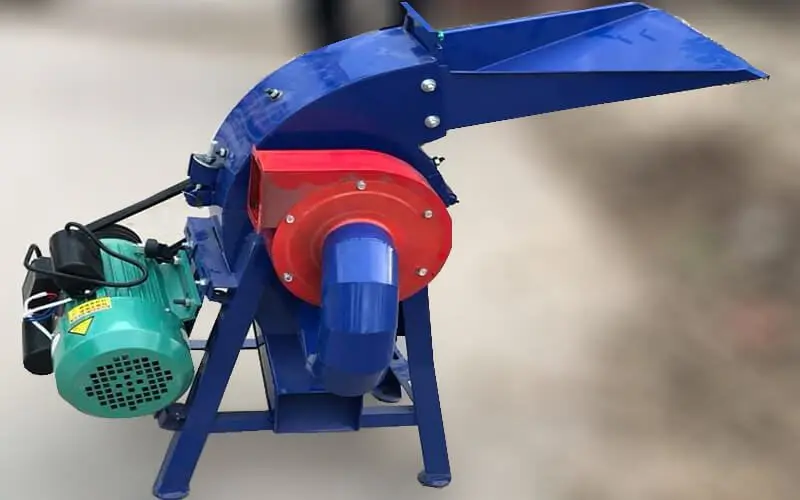

1. The Grinding Section (Hammer Mill): Why Particle Size is Everything.

The job of animal feed crusher machine is to grind raw ingredients into a uniform powder. The right particle size is critical. It helps animals digest the feed easily and helps form a strong, quality pellet.

2. The Mixing Section (Mixer): The Secret to a Balanced Bite.

An anima feed mixer machine job is to blend all the ground ingredients and tiny supplements perfectly. This ensures every single pellet is a complete and balanced meal. An uneven mix means uneven nutrition for your animals.

3. The Conditioning Section (Conditioner): The Most Overlooked, Critical Step.

The conditioner adds steam to the feed mix. This heat and moisture begin to cook the starches, kill some bacteria, and get the mash ready to be pressed into strong pellets. A secret to high-quality feed is a good conditioning process.

4. The Shaping Section: The Big Choice Between a Pellet Mill and an Extruder.

This is where the feed gets its shape. A Feed Pellet Mill is the standard choice for most poultry and livestock feed. It uses pressure to make dense, sinking pellets. An Extruder is a special machine for making floating fish feed or certain high-fat specialty feeds.

5. The Dryer & Cooler: Locking in Quality and Shelf-Life.

These machines get rid of extra moisture from the hot pellets. After that, they let them cool down to room temperature. This step is necessary to make the pellets hard, stable, and safe for long-term storage.

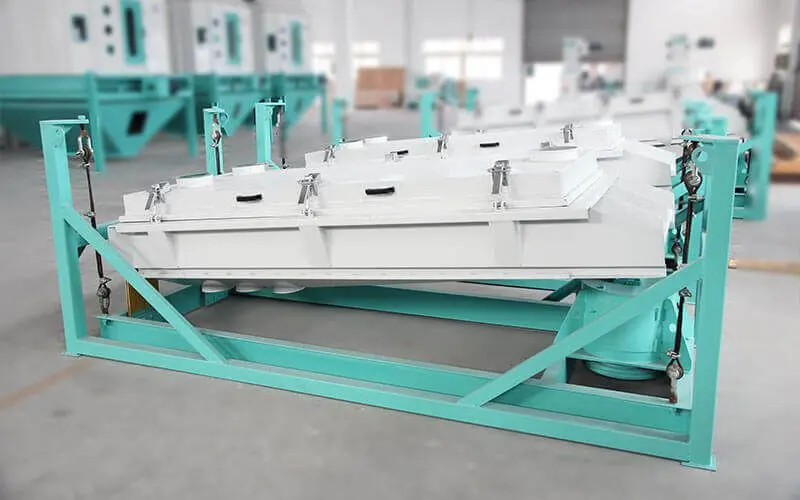

6. The Sifting & Packing Section: The Professional Finish.

A sifter gets rid of any dust or broken pieces, making sure that the final product is the same all the way through. Then, a packer weighs the feed and puts it in bags so it is easy to carry.

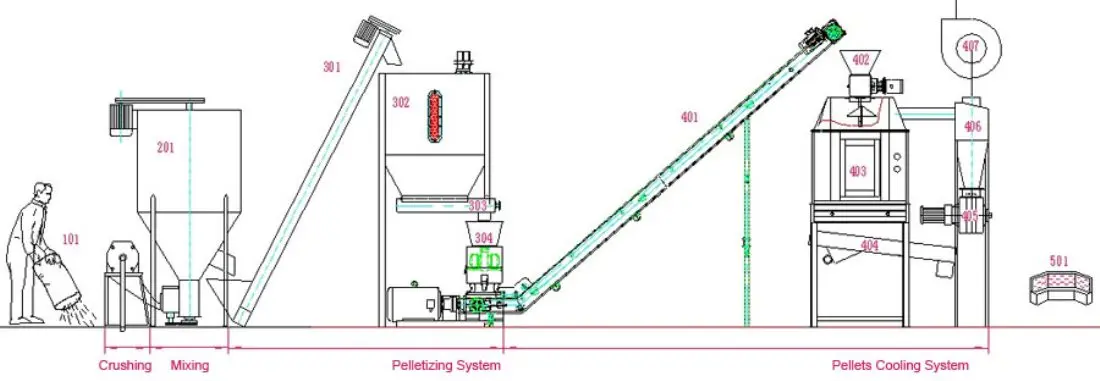

production process for small capacity

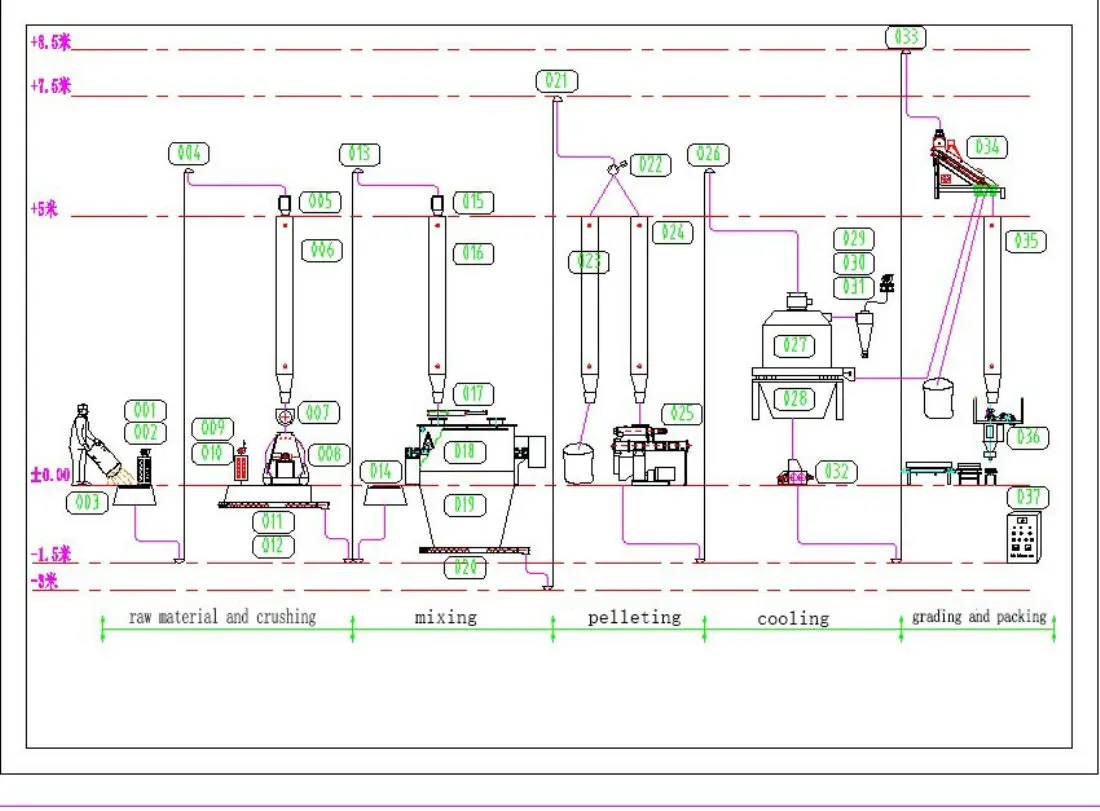

production process for large capacity

animal feed manufacturing process flow chart

small line layout

large layout

A Strategic Checklist Before You Buy

Starting an animal feed processing plant is a big project. Careful planning is the key to success of animal feed business.

1. The Make-or-Break Question: Your Raw Material Supply Chain.

Is it possible to get a steady, dependable, and cheap supply of high-quality ingredients all year long? You need to fix this problem first before you can move on if the answer isn’t a clear “yes.”

2. Know Your Market & Your Capacity Needs (Tons/Hour).

Who buys from you? What kind of food do they need? How much do you need to make to meet the demand?

3. Design Your Facility for Flow and Safety.

Think about logistics for trucks. You will also need space for raw material and finished feed storage. You will also need proper utilities like power and water, and a good plan for dust control.

4. Choose Your Supplier Wisely.

Find machinery suppliers who have a track record of success. They should have reliable tools, good customer service, and be able to get spare parts quickly.

5. Understand the Regulations in Your Area.

You need to look into the laws about making feed in your area and across the country. If you want to sell the feed, this is especially important for safety and labeling.

Common Mistakes to Avoid

- A Good Conditioner Can Make Up for Many Small Problems. “Never skimp on your conditioning process. Proper steam conditioning is often the secret to making strong, durable, and highly digestible pellets that animals love.”

- Thinking the Pellet Mill is the Only Important Machine. “A production line is a chain, and it’s only as strong as its weakest link. Often, that weak link is an underpowered grinder that can’t keep up, or an inefficient cooler that leaves pellets too moist. Every machine in the line is important.”

- Always Plan for More Storage Than You Think You Need. “Plan for more storage space for both your raw materials and your finished feed. It gives you the flexibility to buy ingredients when they are cheap and to handle large orders without stress.”

Conclusion

A production line for animal feed is a complicated, industrial system. It costs a lot of money. It takes a lot of planning and a strong business plan. But for serious farmers and business owners, it gives them more control over feed quality, production costs, and the success of their business than anything else.

FAQ About Animal Feed Production Line

What’s the main difference between a feed plant for poultry and one for cattle?

A: The main process is the same, but the machines may be different. For roughage and larger pellets, cattle feed may need stronger grinders and bigger dies. Poultry farms need good sifters and sometimes a special “crumbler” machine to break up pellets into smaller pieces for young chicks’ starter feed.

Do I need an extruder or a pellet mill for my animal feed production line?

A: This depends on the feed you want to make. For most standard livestock and poultry feed, a pellet mill is the right and most common choice. If you specifically want to make floating fish feed or certain types of high-fat specialty pet foods, then you will need the more specialized and more expensive floating fish feed pellet machine.

How much does it cost to start a small animal feed processing plant?

A: This is a big investment. A small but complete animal feed production plant, like one that makes 1 ton of feed per hour, can cost anywhere from tens of thousands to over a hundred thousand US dollars. The final price depends a lot on how automated the line is, how good the machines are, and how big the animal feed processing line is.

What is the most important factor for making high-quality animal feed?

A: Most experts agree on two things, even though it’s important to have good machines. The most important things are the quality of your raw materials and how well you follow your recipe. A great plant can’t make good feed out of bad ingredients or a bad recipe.

Can I use the same plant to make feed for different animals?

A: Yes, this is one of the best things about having a flexible animal feed processing plant. A single animal feed processing line can make feed for chickens, cows, goats, pigs, and more by changing the recipe and the die in the pellet mill to make pellets of different sizes.