| Price | 3500-50000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Industrial Pellet Mill: 0.5-15T/H Capacity & Ring Die Technology

| Production Output | 0.5-15 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal/cake, edible leaf, fish meal, bone powder, etc |

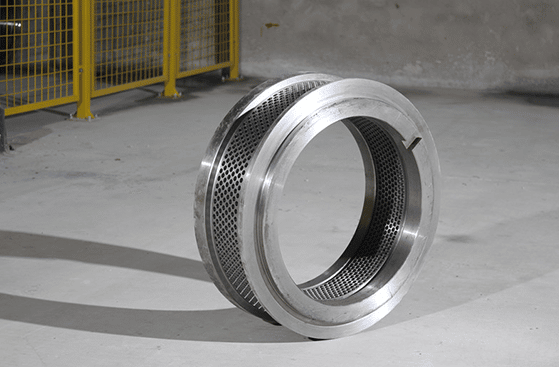

| Type | ring die type |

| Final product size | 2-10 mm |

| Application | industrial or commercial use |

| Used For | animal, poultry, sinking fish feed |

Technical Parameters: Heavy-Duty Pellet Press Systems

| Model | Power(Kw) | Output(kg/h) | Feeding Power(kw) | Conditioner Power(kw) | Ring Die Diameter(mm) | Pellet Size(mm) |

| HMK-250 | 22 | 500-1000 | 0.55 | 2.2 | 250 | 1.5-8 |

| HMK-300 | 30 | 1000-2000 | 0.75 | 2.2 | 300 | 1.5-8 |

| HMK-320 | 37 | 2000-3000 | 0.75 | 2.2 | 320 | 1.5-8 |

| HMK-350 | 55 | 3000-4000 | 1.5 | 3 | 350 | 1.5-8 |

| HMK-400 | 75 | 4000-5000 | 1.5 | 5.5 | 400 | 1.5-8 |

| HMK-420 | 110 | 5000-8000 | 1.52.2 | 5.5 | 420 | 1.5-8 |

High-Speed Pelletizing Process video: 10mm Feed

what is industrial pellet mill?

industrial pellet mill can make a lot of animal food and fish food that sinks. For floating fish food, use our special floating pellet machine. These big machines are made for feed factories to make tons of quality food every day. They keep your business running smoothly with strong, reliable equipment.

Our commercial pellet machines come in three sizes to fit every need. The small one makes 500-1000kg each hour, perfect for family farms. medium machines can make 1-2 tons per hour for growing business.

large pellet mills process over 2 tons per hour, turning farm waste and wood chips into clean fuel pellets that work well in stoves and heaters.

This smart industrial pellet mill solves the problem of thick fibers not sticking together well. large feed pellet mill let business owners make more money with less spending. Learning how these machines work and keeping them clean helps your factory run better for many years.

Industrial-Grade Benefits: Forged Gears & Quick-Die Change

We make industrial pellet mill parts extra strong using special heating methods. The main pieces are built to last with heavy forging. Our quick-clip system lets you change the ring die fast, thus you can save time when changing molds. This tough design keeps your machine working longer with less downtime.

This smart machine uses strong gear power to make more pellets faster than belt machines. It works 20% quicker while using less electricity. Farmers save money on power bills and get more fodder made every day. you need to lubricate the gears every month to ensure the machine can run smoothly.

the gears of our large pellet mill get treatment through high temperature heating, so it is superly strong. The teeth of the gears fit together perfectly for smooth running.

You’ll hear less noise than old machines, and these tough parts last many years without wearing out. you need to check the oil levels every week to ensure the industrial pellet mill can work like a new one.

Adopt improved U-shaped screw conveyor. Its adjustable food rate allows continuous feeding without clogging.

raw materials for large pellet mill

Rapeseed Meal, cotton seed meal:

the food with high-protein can give animals more energy that they need. Each scoop has 38% protein for strong muscles. It also has 12% natural plant fibers and special compounds from canola or mustard plants. people mix it with other raw materials to keep animals healthier and watching how much they eat.

corn, maize, soybean, rice, wheat:

contain about 10-14% of protein and also contain vitamin B1, B2, B6 and small quantity of enzyme.

the industrial pellet mill can turn corn, beans and wheat into feed pellets without grinding. But for straw or alfalfa, you need to crush them into powder first.

When making animal food from one ingredient, skip the mixer. Always use the mixer when combining different feeds to make sure every bite has the same good stuff for your animals.

Multi-Purpose Pelletizing: Feed Production & Biomass Conversion

Turn corn, soybeans, rice or wheat into food pellets with no grinding needed. Just pour whole grains into the machine’s special chamber. Watch them become ready-to-use pellets automatically. This smart industrial pellet mill saves time and energy while keeping all the good nutrients in the fodder.

industrial pellet mill can make animal and livestock feed, such as for cattle, chicken, pig, goat.

turning straw,grass,hay meal into pellets for animal food and heating fuel. if you want to use wood as raw materials, you can use our wood pellet mill.

processing life garbage and other green plants into pellets for livestock and animal food.

structure of commercial pellet machine

industrial pellet mill work like magic kitchens for animals. The smart feeder pushes ingredients forward while steam mixes with dry food to make it sticky. strong gears and safety stopping buttons keep the machine running smooth and sately.

this commercial pellet mill makes meals fast perfectly, and saves time and money for farmings. Clean the steam mixer weekly to keep it working like new. This sealed mixing box uses spinning blades to mix dry meals, steam and liquids perfectly.

The smart feeder keeps the flow just right, like a traffic light for animal food. Farmers get even blending every time, which makes better meals and saves energy. Check the blade tightness monthly to keep your mix consistent.

You control how much material goes into the industrial pellet mill with the feed rate. Set the right speed to keep the motor safe and strong. This smart control saves power and keeps your machine running longer. Always check the speed dial before starting to make perfect pellets every time.

Nutrition Retention Science: rich Protein Preservation in Pellets

Dry pellet making is super simple. When using mash or grass meal, you don’t need to add water. The pellets stay just as dry as the original food. the pelleting method can keep animal food fresh longer and save storage space. Always check the feed bag’s dryness before use for best results.

the mixture has a smooth coat stay that is easy to chew for animals. all the good stuff goes into animal body that they need. animals are more and more healthier but fodder is wasted less. you need to check fodder texture weekly to keep it at its best.

the industrial pellet mill can process different food with rich nutrients. so animals can eat more. The hard pellets make animals chew longer, which can help their stomachs work better.

people save money without wasted fodder and animals are more and more healthier. Always test pellet hardness monthly with your thumb to keep meals working right.

when you make feed pellets, heating changes materials nutrients to help animals to digest better. this can kill bad germs and worm eggs that will make animals sick.

Your cows stay healthy with cleaner food that works well in their stomachs. Check the food temperature weekly to keep this safety magic working right.

grab economic benefits. It is more affordable than feed.