| Production Output | Range from 0.1-2 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | rice, corn, wheat, barley, soybean, leaf, fish meal, grass, hay, straw etc. |

| Type | flat die type |

| Final product size | 2-12 mm |

| Used For | feed pellets for cattle, pig, sheep/goat, deer etc. |

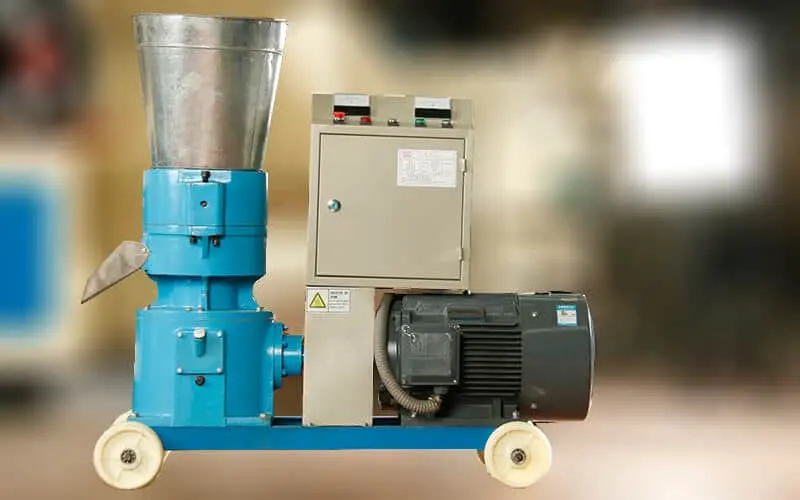

Multi-functional Animal Feed Pellet Mill

Our multi-purpose animal feed pellet mill features a flat die design, specifically tailored for small to medium-sized mixed-use farms.

The machine can make different pellets for livestock like cattle, sheep, pig, and horse. farmers do not need to purchase dedicated feed pelletizing equipment for each animal type, significantly reducing your equipment investment costs and floor space.

The core advantage of animal feed pellet machine is its quickly changeable die plate, allowing for easy adjustment of pellet diameter, density, and shape, enabling rapid switching between feed applications.

Industry data shows that small to medium-sized farms using the multi-purpose pellet making machine achieve approximately 25%-40% higher feed production efficiency compared to traditional single-purpose pellet machines, while simultaneously achieving balanced feed nutrition and optimized digestibility.

This “one machine, multiple uses” design not only enhances the flexibility of farm management but also provides long-term economic benefits for mixed-use farms. You can check our cattle feed pellet mill for ruminants.

how does animal feed pellet machine work

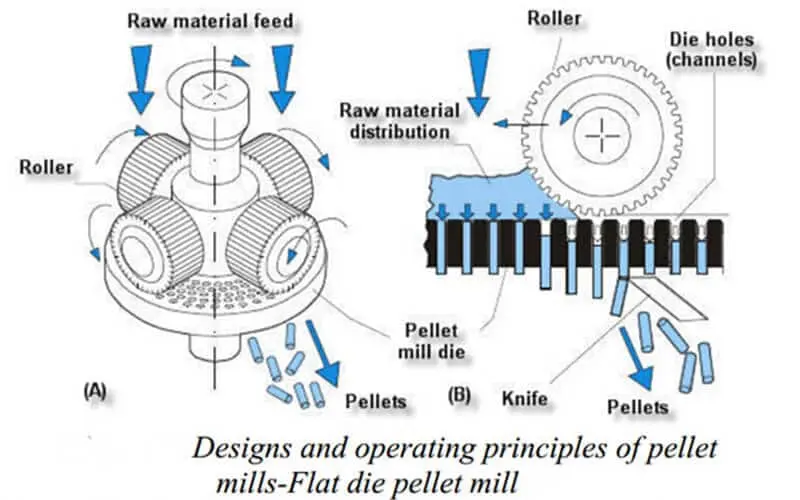

Animal feed pellet mills utilize the synergistic action of pressure rollers and dies to precisely and efficiently convert powdered raw materials into high-density pellets. The main processes are as follows:

- Raw Material Preparation and Feeding: Uniformly ground and mixed raw materials (adjusted to a moisture content of 10-15%) are fed into the feeding hopper and fall evenly into the pelletizing chamber by gravity. This ensures uniform material distribution.

- Roller Rotation and Feeding: The rolling rollers above the die begin to rotate, pressing the raw materials against the die surface. Under the influence of gravity and inertia, they are uniformly expanded, preparing them for high-density pellet formation.

- High-Pressure Compression: The squeeze rollers apply vertical pressure, forcing the raw materials through the die opening. Friction and pressure generate high temperature about 75-85 degrees in the raw materials, promoting adhesion and maturation while also forming a dense pellet structure beneficial to animal digestion and absorption.

- Cutting by cutter: The extruded long pellet strip is cut to a set length by a fixed or rotary cutter to form uniform pelleted feed.

- Discharge and cooling: The hot, soft pellets discharged from the discharge outlet must be cooled to room temperature in a cooling device to harden, making them easier to store and transport.

According to industry data, small and medium-sized aquaculture farms using multifunctional animal feed pellet making machines have achieved a 25-35% improvement in pelleting efficiency compared to conventional single-function machines, and the pellet density has been made more uniform, resulting in significant improvements in feed conversion rate and nutrient absorption rate.

Why choose a multi-functional Animal Feed pellet mill? (Benefits and advantages)

Analysis of Reduced Initial Investment Costs

The multi-functional animal feed making machine, with its simple structure and low maintenance costs, significantly reduces capital expenditure during the equipment procurement stage.

Compared to ring die type feed pellet mills, the initial investment for an animal feed pellet mill can be reduced by approximately 50% to 60% under the same output conditions, and it eliminates the need for additional steam systems or complex conditioning devices.

This makes it an ideal solution for small and medium-sized farms and mixed feed processors to control CAPEX (equipment purchase costs) during the initial construction phase.

Advantages of Pellet Density and Palatability

The pelleting process can stably produce feed pellets with high density and moderate hardness, exhibiting good structural strength and palatability.

These pellets are particularly suitable for supplementing roughage in ruminants such as cattle and sheep, and also meet the needs of pigs, poultry, and some aquatic animals for sinking feed. The uniform density structure resulting from high-pressure extrusion molding helps improve feeding efficiency and nutrient absorption.

Improving Farm Operational Efficiency and Space Optimization

The multi-functional animal feed pellet mill features a compact design, typically occupying less than 1-2 square meters, effectively saving production space.

Operationally, only one person is needed to handle feeding, die replacement, and routine maintenance, significantly reducing labor costs and improving operational efficiency.

For small and medium-sized farmers, this type of feed pelletizing equipment not only simplifies the production process but also enables the establishment of a stable feed production system within limited space, achieving a cost-effective feed processing model.

One Machine, Multiple Uses: Scientific Matching of Mold Apertures to Animals

Animal species and mold plate aperture comparison table

The table below provides standardized reference parameters for different animal species, feeding stages, and die sizes, serving as a key decision-making basis for the selection and application of multi-functional animal feed pellet mills.

The data is based on industry-standard parameters and actual production experience from mainstream farms, facilitating users to quickly match suitable pellet diameters and optimize feed palatability and compaction density.

| Application | Recommended growth stage | Recommended Die Size | Feed characteristics |

|---|---|---|---|

| rabbit / pig | Growth period / fattening period | 3.0mm – 5.0mm | universal diameter, meets energy intake requirements, and has a stable structure. |

| Cow/Sheep/Rough Fiber Grass Pellets | Full Stage | 6.0mm – 12mm+ | High hardness and high fiber retention capacity meet the nutritional needs of ruminants. |

Simple Steps for Die Replacement

This multi-functional feed pellet making machine features a standardized die design, enabling efficient and convenient die replacement. Operators simply loosen the pressure roller fixing bolts to remove the old die and install a new die that matches the target pellet size (e.g., 3mm, 6mm, 10mm).

Subsequently, a special adjustment tool is used to adjust the gap between the pressure roller and the die, typically maintaining it between 0.1–0.3mm. This ensures uniform material compression, stable pellet formation, and prevents abnormal wear.

The entire replacement process usually takes only a few minutes, minimizing downtime while significantly improving the feed production equipment’s adaptability to various crops and formulation scenarios. This mechanism is crucial for hybrid farms seeking highly flexible pellet production.

The Effect of Compression Ratio on Pellet Hardness

The compression ratio of the die plate is a critical technical parameter for animal feed making machine. Defined by the ratio of the effective length to the diameter of the die holes, it directly determines the hardness, density, and chew resistance of the final pellets.

High compression ratio die plates are typically used for processing high-fiber forage for ruminants such as cattle and sheep. They produce denser, harder pellet structures, thereby improving chewing efficiency and prolonging digestion time.

Conversely, when processing high-starch materials like corn or soybean meal, low-compression-ratio die plates are recommended to reduce pelletizing resistance, lower energy consumption, and maintain palatability.

Selecting an appropriate compression ratio not only impacts pellet quality but also helps optimize overall machine load and long-term operational stability, making it a core technical consideration in pelletizing performance control.

FAQ

A: No. It presses use high pressure to create high-density sinking pellets, suitable for livestock, poultry, and bottom-dwelling fish. For floating pellets, you must use floating fish feed pellet mill.

A: The main factors depend on the main unit’s power (5.5–30kW), the die diameter, and the material and brand grade. Higher power and larger die diameter result in higher output, but also increase the equipment price.

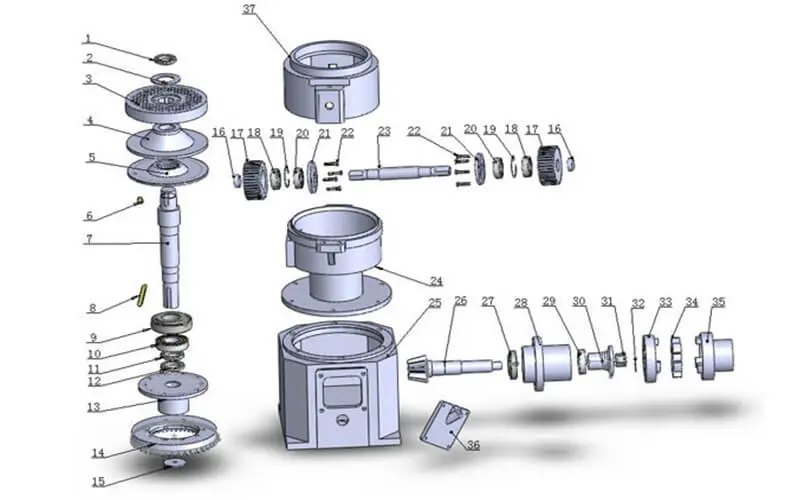

A: The core wear parts are the die plate and the pressure rollers, which typically need to be inspected or replaced after 300–500 tons of operation. Routine maintenance includes lubrication, cleaning the die holes, and checking the clearance of the pressure rollers.

Raw Materials For Animal Feed Pellet Making Machine

Applicability of Grains and Energy Sources

This animal feed pellet mills are widely compatible with grains and energy feed ingredients, and can stably process common feed formulation ingredients such as corn flour, soybean flour, wheat bran, and rice bran.

According to industry validation data, if the raw material has a flour content of over 90% and maintains a uniform moisture content of 10%–15%, the pelleting success rate and pellet formation rate can be increased by 12%–18%. Within this moisture content range, the plasticity and frictional heat effects of the raw material are most stable, resulting in animal feed pellets with uniform density and moderate hardness.

This characteristic makes the animal feed machine highly adaptable and economical in standard livestock and poultry feed, small-scale agricultural processing, and family farm scenarios.

Processing Capacity for High-fiber Forage and Straw

For structured raw materials such as high-fiber forage (e.g., alfalfa meal), straw meal, and bamboo meal, the die presses also possess good pressing capabilities, but key pretreatment steps must be ensured.

Industry experience shows that pulverizing coarse-fiber raw materials to a fineness of less than 3mm significantly reduces the probability of die clogging and improves production stability.

Pretreatment with a specialized pulverizer can increase the compressibility of high-fiber materials by more than 20%, making them more suitable for forming high-hardness forage pellets in the feed presses, thus meeting the core needs of ruminant feeding.

Power type selection: Electric motor vs. Diesel engine

Which power source should I choose?

Electric Motor Type

Electric motor-driven animal feed pellet mills are suitable for farms with a stable and sufficient three-phase industrial power supply and a fixed machine location. This type of drive has the lowest operating costs, simple structure, and convenient maintenance, making it ideal for farms seeking long-term economic benefits.

Diesel Engine Type

Choosing a diesel engine drive is suitable for farms in remote areas, without a fixed power source, or where frequent relocation of the pellet mill is required. Diesel engines offer high power and flexibility, capable of handling large-scale forage processing or multi-site operations, but fuel costs and maintenance requirements must be considered separately.

Additional Costs and Maintenance Considerations for Diesel Engine Drive

While diesel engines offer flexibility, they come with additional costs and operational requirements: fuel prices fluctuate significantly, oil and filter changes are needed every 200–300 hours, and noise and emissions are higher than electric motors. Farmers should weigh mobility, power requirements, and maintenance burden when choosing a feed pellet mill to ensure long-term, efficient operation.

electric feed pellet mill

diesel engine feed pellet mill

electric feed pellet mill

| Model | Electric Power(kw) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 3 | 50-80 | 80 |

| VTKLP-150 | 4 | 100-150 | 110 |

| VTKLP-210 | 7.5 | 200-400 | 210 |

| VTKLP-230 | 11 | 300-500 | 280 |

| VTKLP-260 | 15 | 500-700 | 300 |

| VTKLP-300 | 18.5 | 700-900 | 500 |

| VTKLP-360 | 22 | 900-1200 | 700 |

| VTKLP-400 | 30-37 | 1200-1500 | 900 |

diesel engine feed pellet mill

| Model | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 4 | 50-80 | 100 |

| VTKLP-150 | 5 | 100-150 | 150 |

| VTKLP-210 | 10 | 200-400 | 260 |

| VTKLP-230 | 15 | 300-500 | 350 |

| VTKLP-260 | 20 | 500-700 | 420 |

| VTKLP-300 | 25 | 700-900 | 650 |

| VTKLP-360 | 30 | 900-1200 | 900 |

| VTKLP-400 | 40-50 | 1200-1500 | 1200 |