| Price | 500-6000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

VTKLP Alfalfa Pellet Machine: 0.1-2T/H & Dual-Power (Electric/Diesel)

| Production Output | 0.1-2 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | grass, hay, alfalfa, straw, cereal, corn, wheat, barley flour, soybean, oil seed meal/cake, edible leaf, fish meal, bone powder, etc |

| Type | flat die type |

| Final product size | 3-10 mm |

| Application | feed pellet producing, feed pellet industry |

| Used For | animal feed production, alfalfa pellet production, fuel pellet production |

Electric vs Diesel Models: 50-1500kg/h Output & Energy Cost Comparison

electric motor

| Model | Electric Power(kw) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 3 | 50-80 | 80 |

| VTKLP-150 | 4 | 100-150 | 110 |

| VTKLP-210 | 7.5 | 200-400 | 210 |

| VTKLP-230 | 11 | 300-500 | 280 |

| VTKLP-260 | 15 | 500-700 | 300 |

| VTKLP-300 | 18.5 | 700-900 | 500 |

| VTKLP-360 | 22 | 900-1200 | 700 |

| VTKLP-400 | 30-37 | 1200-1500 | 900 |

diesel engine

| Model | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 4 | 50-80 | 100 |

| VTKLP-150 | 5 | 100-150 | 150 |

| VTKLP-210 | 10 | 200-400 | 260 |

| VTKLP-230 | 15 | 300-500 | 350 |

| VTKLP-260 | 20 | 500-700 | 420 |

| VTKLP-300 | 25 | 700-900 | 650 |

| VTKLP-360 | 30 | 900-1200 | 900 |

| VTKLP-400 | 40-50 | 1200-1500 | 1200 |

What is an Alfalfa Pellet Mill?

An alfalfa pellet mill makes alfalfa into uniform pellets that make it easier to sort, keep nutrients stable, and clean up the stalls. The useful moisture range is 14–16% lower than that of pellets powder; anything higher will block the die. When the moisture and conditioning are right, binders are usually not needed because the natural parts of alfalfa become plastic when they are heated and pressed.

Benefits of Using an Alfalfa Pellet Machine

Consistent nutrition, less dust, and calmer eating. Each pellet has a protein and calcium profile that can be repeated. Horses and picky eaters can’t pick and choose leaves, so less waste is made. Less dust in the air is better for animals with sensitive lungs.

Reclaim Your Barn Space

The best thing about it is that it saves you space. Alfalfa pellets are a lot thicker than loose hay. This means you can keep the same amount of food in a lot less space. This makes a lot of valuable space in your barn available for other important things.

End Picky Eating and Waste

You know the problem if you have horses or other picky eaters. They will look through a pile of hay to find the best leaves, pulling out the rest and trampling it into their bedding. Pellets fix this problem completely. Each pellet is a full bite, which can greatly reduce the amount of feed that ends up on the ground.

Guarantee Consistent Nutrition in Every Bite

When an animal eats loose hay, it’s like they’re at a salad bar because they can choose what they want. This means they don’t always get a meal that is balanced. Every pellet has the same mix of healthy leaves and fibrous stems. This makes sure that every bite your animals take gives them the same, balanced nutrition.

A Cleaner, Healthier Environment

Alfalfa pellets make a lot less dust than hay that is loose. This is a big health benefit for animals with sensitive breathing systems, like a lot of horses. This also means that the air in your barn will be cleaner and healthier for you and your animals.

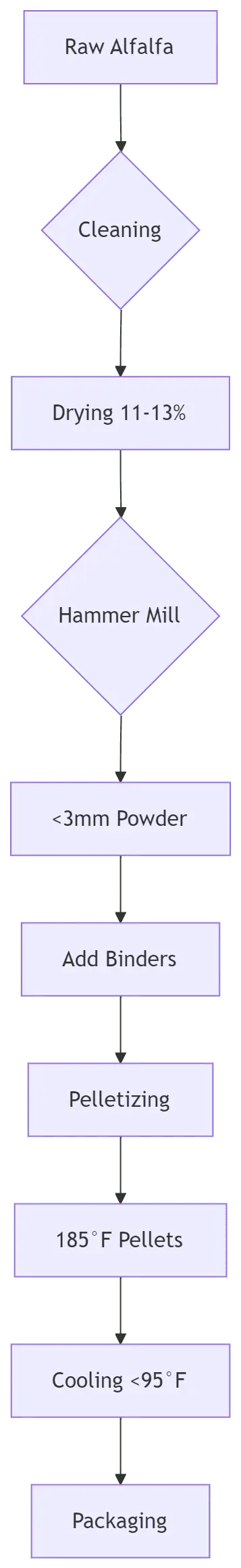

Alfalfa Pellet Production Workflow

You can check the blogpost about how to make alfalfa pellets in details.

How to Choose the Right Alfalfa Pellet Machine

Think about how many people you can serve and how big the herd is. When you scale up, think about pre-conditioners and how much size they can handle. Check the spare parts path—die, rollers, bearings, seals—and the usual lead times. Choose electric when you can; PTO/diesel works in barns that are far away.

A Quick Look at the Process: How Alfalfa Becomes a Pellet

Condition for animals, not for furnaces.

1) Grind dry alfalfa with a hay grinder/hammer mill to small, uniform particles.

2) Adjust moisture to 14–16% (light water or steam).

3) Press with a die suited to alfalfa fiber.

4) Cool fully before bagging; hot pellets sweat and soften in storage.

FAQ About Alfalfa Pellet Machine

1. What exactly does an alfalfa pellet machine do?

It is a machine that makes pellets out of loose, ground alfalfa hay by putting a lot of pressure on it. This easy process turns a large piece of forage into a small, easy-to-use product that can be used as animal feed or even as biomass fuel.

2. Do I really need a separate grinder for the hay?

Yes, for sure. This is the first step that can’t be changed. An alfalfa pellet making machine can’t handle hay that is long and stringy. Before you can make pellets, you need to chop the alfalfa into small, even pieces with a different machine, like a hammer mill or a hay grinder.

3. What is the single most important secret to making good pellets?

Getting the moisture level of your ground alfalfa just right is the most important part of the whole process. Your pellets will be dusty and fall apart if it’s too dry. You will end up with a mushy mess that will stop your machine if it gets too wet. The key to success is to master this.

4. Do I need to add molasses or another binder?

Usually, you don’t. Alfalfa has natural compounds that, when combined with the heat and intense pressure inside the pellet mill, are enough to bind the pellet together firmly. Focusing on getting the moisture level correct is far more important than using any extra binders.

Conclusion

If you’re a modern farmer, you should get an alfalfa pellet machine. It changes your big, hard-to-handle hay into small, easy-to-use pellets. This easy change saves you space and cuts down on feed waste.

When you pick one, make sure the size and power source of the alfalfa pellet press machine are right for your farm. And don’t forget that you’ll need a different grinder to get the hay ready first. It’s a smart investment that lets you have more control over your feed and how well your farm runs.