The Heart of Aquaculture: Maintaining Fish Feed Machines in India

Aquaculture has been booming in India, a country blessed with vast coastal regions and a rich tradition of inland fishing. Along with this surge in fish farming, the demand for efficient fish feed making machine in India has grown significantly.

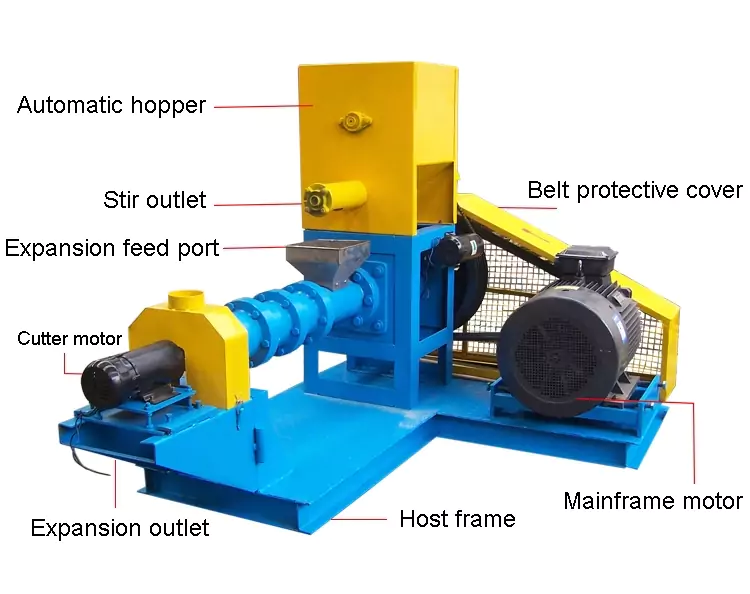

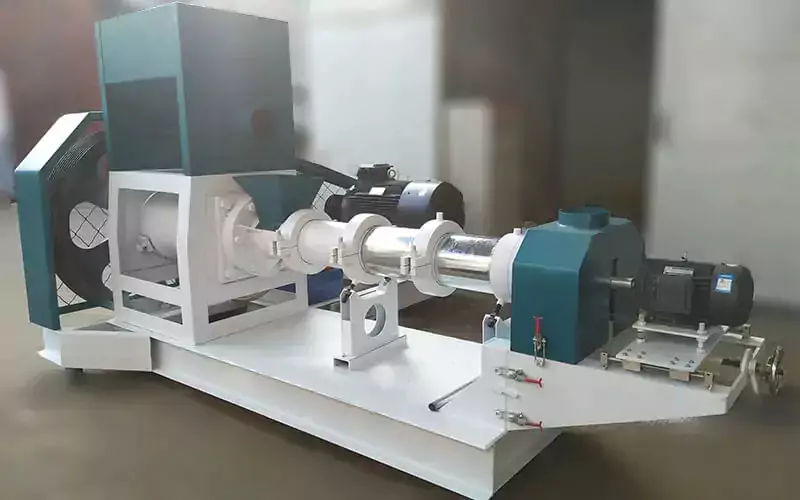

These floating feed machines, the heart and soul of many fish farms, play a crucial role in ensuring a consistent and nutritious diet for the fish. They automate the process of producing high-quality feed, tailored to the specific needs of different fish species.

But like any advanced machinery, floating fish feed machines require regular maintenance and care. Without proper attention, these vital pieces of equipment can suffer from wear and tear, leading to inefficiency or even breakdowns.

Let’s dive into the essential maintenance tips for fish feed machines in India that can keep them running smoothly for years to come. By following these maintenance tips for fish feed machines in India.

Fish farmers can ensure that their floating feed production remains optimal, thereby supporting the healthy growth of their fish and contributing to a more sustainable and profitable aquaculture industry in India.

video of how to maintain fish feed extruder machine

Understanding the Importance of Maintenance

floating fish feed machines are vital in producing quality feed that meets the specific requirements of different fish species. Regular maintenance doesn’t just keep the machine functioning, no matter your machine is floting fish feed pellet machine or sinking fish feed machine, it ensures that your fish are getting the best possible nourishment. So, what’s the secret sauce for maintaining these machines?

Comprehensive Maintenance tips for fish feed machines in India

By following these maintenance tips for fish feed machines in India, fish farmers can ensure that their feed production remains optimal, thereby supporting the healthy growth of their fish and contributing to a more sustainable and profitable aquaculture industry in India.

Regular Cleaning:

After each usage, clean the machine’s parts thoroughly to remove any residual feed or dust. This prevents clogging and ensures smooth operation.

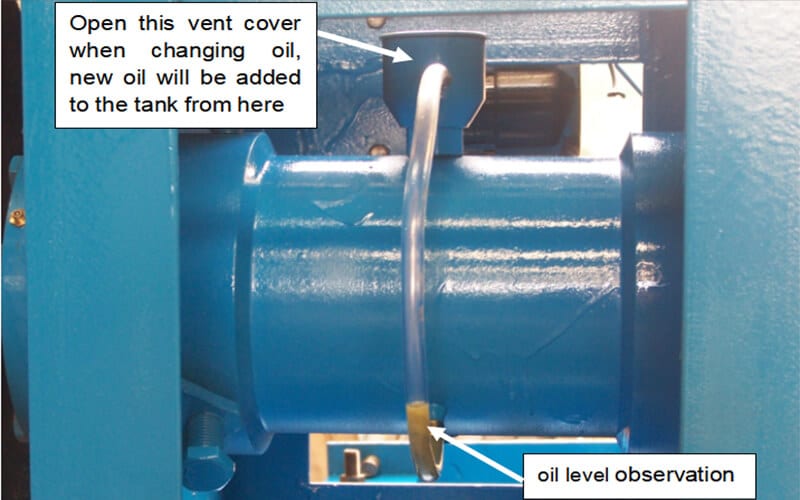

Lubrication:

Apply lubricants to the moving parts as specified in the machine’s manual. Regular lubrication minimizes friction and wear.

Inspection of Wear Parts:

Regularly inspect the wear parts like dies, rollers, and knives. Replace them if needed to maintain optimal performance.

Electrical Maintenance:

Ensure that the wiring and electrical components are in good condition. Any faulty connections or damaged parts should be repaired or replaced immediately.

Calibration:

Regular calibration ensures that the machine delivers the exact quantity and quality of feed required. It helps in maintaining consistency in feed production.

Software Updates:

If your machine has digital controls, keep the software up-to-date with the latest updates from the manufacturer.

Compliance with Manufacturer Guidelines:

Always follow the manufacturer’s guidelines regarding maintenance schedules, part replacements, and specific procedures.

Where to Buy Fish Feed Machines and Parts in India?

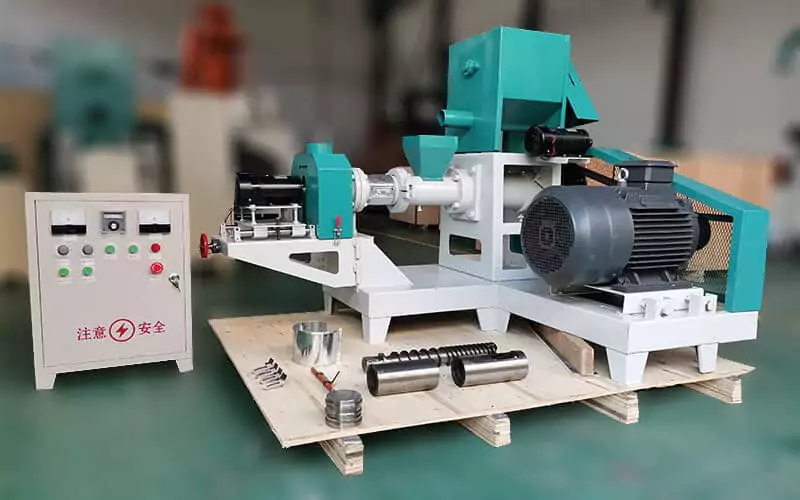

Looking for the perfect floating fish feed machine or need some spare parts? Many manufacturers offer various machines at different price points. Explore options and consult with professionals to find one that fits your farming needs.

The Cost Aspect: An Investment Worth Making

Investing in maintenance may seem like an added expense, but it’s an investment that pays off. Regular upkeep reduces the chance of costly breakdowns. Think of it like buying good quality shoes; they might cost a bit more initially, but they last longer.

Usage Instructions: Operating Your Fish Feed Machine

Operating a floating fish feed machine requires careful attention to details and understanding the particularities of the equipment. By adhering to these detailed instructions.

Maintenance tips for fish feed machines in India and operating floating fish feed making machine becomes a well-coordinated process that ensures both efficiency and quality in making fish feed.

It turns a complex piece of machinery into an accessible tool that can be mastered with careful attention and practice. Here’s a step-by-step maintenance tips for fish feed machines in India to ensure seamless operations:

1.Preparation Phase

Gather Ingredients: Before starting the machine, make sure you have all the necessary ingredients as per the feed formulation.

Inspect the Machine: Check all parts for wear and tear. Ensure everything is cleaned and lubricated.

Review the Manual: Every machine comes with specific operating instructions from the manufacturer. Familiarize yourself with these to prevent mistakes.

2.Setting Parameters

Choose the Feed Type: Select the desired feed type – floating or sinking, and set the size and shape according to your fish species’ requirements.

Adjust Temperature and Moisture Controls: Some feeds require specific temperature and moisture levels. Set these according to the guidelines for the particular feed you’re producing.

Set Production Speed: Adjust the speed of the floating fish pellet machine depending on the quantity you want to produce.

3.Loading Ingredients

Feed the Ingredients into the Hopper: This should be done gradually, observing the machine’s capacity guidelines to avoid overloading.

Monitor Ingredient Mixing: Some floating pellet machines come with transparent sections or indicators to let you know if the ingredients are mixing evenly.

4.Monitoring Production

Keep an Eye on the Output: Regularly check the output to make sure it meets the desired quality standards.

Be Alert for Any Irregularities: Listen for unusual noises or vibrations, which could indicate a problem.

5.Cleaning After Use

Daily Cleaning: Removing feed residue daily prevents buildup and potential contamination.

Weekly Deep Cleaning: Depending on the feed’s composition and the floating fish pellet machine’s usage, a weekly deep cleaning might be necessary.

6.Maintenance Routine

Regular Inspections: Besides daily operations, set a schedule for more in-depth inspections of parts like dies, rollers, and bearings.

Log Your Activities: Keep a maintenance log. Noting down daily operations and any issues helps in troubleshooting and ensures consistent quality.

7.Safety Measures

Follow Safety Guidelines: Always follow the manufacturer’s safety instructions to prevent accidents.

Use Protective Equipment: Depending on the floating pellet making machine and the environment, the use of gloves, masks, or other protective gear may be advisable.

8.Record-Keeping

Maintain Production Records: Documenting production details, including the feed type, quantity produced, and any adjustments made during production, can help with quality control and future planning.

Conclusion: Keep Floating with Proper Care

Maintaining fish feed machines in India isn’t rocket science, but it is essential. By following these maintenance tips for fish feed machines in India and understanding how to properly use the floating pellet feed making machine, you’re ensuring that your entire aquaculture operation keeps floating smoothly.