A Guide to the Fish Feed Extrusion Process

It is very important to know how to make fish feed. The method is called the fish feed extrusion process. It is the key to making high-quality food for fish farms. High quality feed will give fish the best nutrition and help them grow healthy and strong.

This knowledge of fish feed extrusion process is highly useful for everyone in the fish feed business or fish farming. It does not matter if you make your own fish feed, sell the feed, or making feed for your fish farm.

Understanding how extrusion works can help you and your work a lot. This guide will explain the process in a simple way. We will look at all the steps and show the difference between feed that floats and feed that sinks.

video of floating fish feed extrusion

What is the Process of Extrusion in Fish Feed Production?

Understanding Fish Feed Extrusion Technology

The fish feed extrusion process transforms raw ingredients into nutrient-rich fish food. This can make customized pellets that meet specific fish needs by using precise heating and pressure control. The floating feed is best for surface-feeding fish.

Key Stages in Quality Fish Feed Production

Selecting Premium Ingredients

Every successful batch starts with top-quality fish feed ingredients. Farmers and feed plants prioritize three essential elements: 1. protein-rich fish meal for growth, 2. energy-providing grains like corn, and 3. vital oils for fish health. Then what is the golden rule? Better inputs mean healthier fish and higher profits.

Precision Grinding Process

Powerful hammer mill fish feed grinder machine can grind all dry materials to fine powder. This uniform mixture allows perfect blending of nutrients, it is just like making flour for baking. The finer the grinding, the easier fish can digest their food.

Smart Mixing Solutions

Industrial fish feed mixer machine can blend powder materials with scientific accuracy. Modern advacned mixer machines can blend 500kg in under 10 minutes while maintaining exact proportions. This mixing step make sure every pellet has balanced nutrition from edge to center.

Steam Conditioning Magic

Controlled steam injection activates natural binding agents in the extrusion. The ideal temperature about 80-90°C and moisture level at about 18-22% prepare the dough-like mass for shaping. This extrusion process can boost starch digestibility by up to 40%.

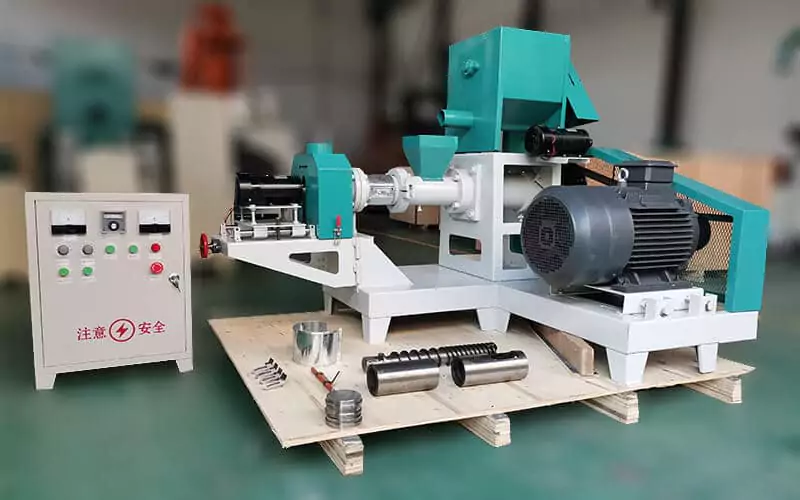

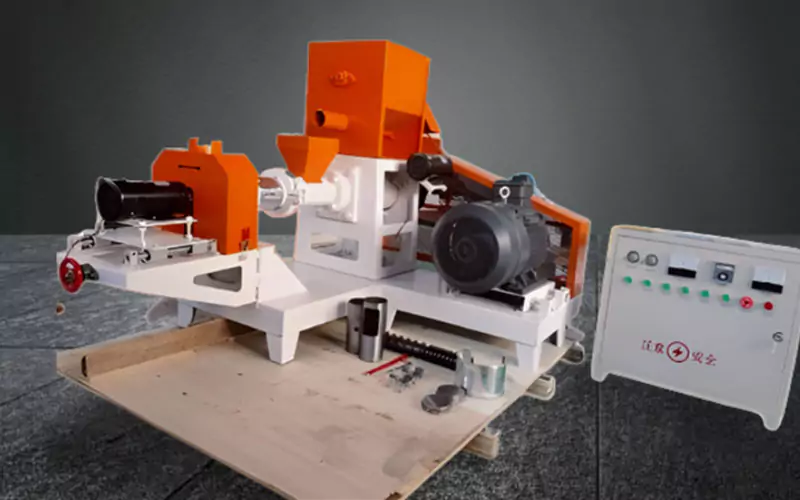

Core Extrusion Science

Inside the fish feed extruder barrel, rotating screws generate intense heat (130-150°C) and pressure (20-40 bar). This combination gelatinizes starches and expands the mixture. As the molten feed exits through custom-shaped dies, precision knives cut it into uniform pellets.

Advanced Drying Techniques

Freshly extruded pellets contain 25-30% moisture – too high for storage. Multi-layer belt dryers gently reduce this to 8-10% using staged temperature zones. Proper drying prevents mold while preserving heat-sensitive vitamins.

Cooling for Quality Preservation

You also need to cool the pellets after drying. Because the pellets temperature is still very high after drying. Counterflow cooler machine use ambient air circulation to reduce temperatures down for safe storage. This critical cooling step is also important which can lock in more nutrients and prevent condensation in packaging.

Rigorous Quality Assurance

You must follow strictly the three key checks after every production batch:

- Analysis Nutrition with NIR spectroscopy

- Pellet durability index testing

- Safety screening for contaminants

Smart Packaging Solutions

Automated bagging systems use oxygen-barrier materials with UV protection. Modern mills offer flexible packaging sizes – from 5kg bags for small farms to 1-ton bulk orders for commercial operations.

Application: How Extrusion Creates Floating vs. Sinking Pellets

You can make your fish farming business more successful when you choose the right fish feed type. Floating and sinking fish feed both will work best for different fishes. Let us explore how smart farmers make this important decision.

Understanding Floating Feed

How It Works

Special puffing techniques create air pockets in the floating fish feed pellets. These tiny bubbles make the feed stay on water’s surface for more than 4-6 hours, which is perfect for tilapia or catfish that snack near the top.

Why Farmers Love Floaters

- See What’s Eaten: Watch fish munching will help spot sick ones early

- Save Money: Retrieve uneaten food with nets (up to 20% less waste)

- Easy for Fry: Baby fish find surface food easier to eat

Watch Out For

- Not for bottom-dwellers like shrimp

- Direct sunlight can break down nutrients faster

The Science of Sinking Feed

How It’s Made

High density pellets will sink slowly to the bottom of the water. This matches how seabass or carp naturally feed at different depths in lakes or ponds.

Best Uses

- Deep Water Fish: Feeds species living 2+ meters down

- Cold Weather: Stays edible longer in cool temperatures

- Big Fish: Mature fish prefer chasing sinking bits

Challenges

- Hard to track exact eating amounts

- Needs special feeding trays for clean ponds

Smart Choosing Guide

Use this pro method to decide:

- Check Fish Mouths: Surface feeders have upward-facing mouths

- Test Water Depth: Under 1.5m? Floating pellets will work better

- Count Your Fish: Over 5,000? You should better make both types of feed for best growth