| Price | 19000-120000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Product Overview

| Production Output | 0.5-15 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal, fish meal, bone meal, meat etc |

| Type | flat die type and ring die type |

| Final Pellet Size | 0.9-10 mm |

| Application | sinking pellets |

| Used For | sinking fish feed production |

Introduction

It is a complicated engineering challenge to design a high quality sinking fish feed production line. It is more than just purchasing a set of feed machine. The final goal is to setup a complete system that can produce high quality feed pellets with maximum efficiency.

Bad design at the beginning can cause major problems which can lead to production bottlenecks, high energy use, and lower profits for years.

This is a technical guide for building or expanding a sinking fish feed production line. We will go beyond the basics to analyze critical design choices for each section of the plant.

This covers the entire process, from raw material intake to the final product. The focus is on efficiency, quality control, and smart scaling strategies for your feed production line.

The Foundation of Design: Defining Your Final Product Specifications

A good design process always starts with the end goal in mind. Before you choose any equipment for your aquatic feed production, you must clearly define the key performance indicators (KPIs) of the sinking feeds you intend to produce.

Key Performance Indicator

1: Pellet Durability Index (PDI)

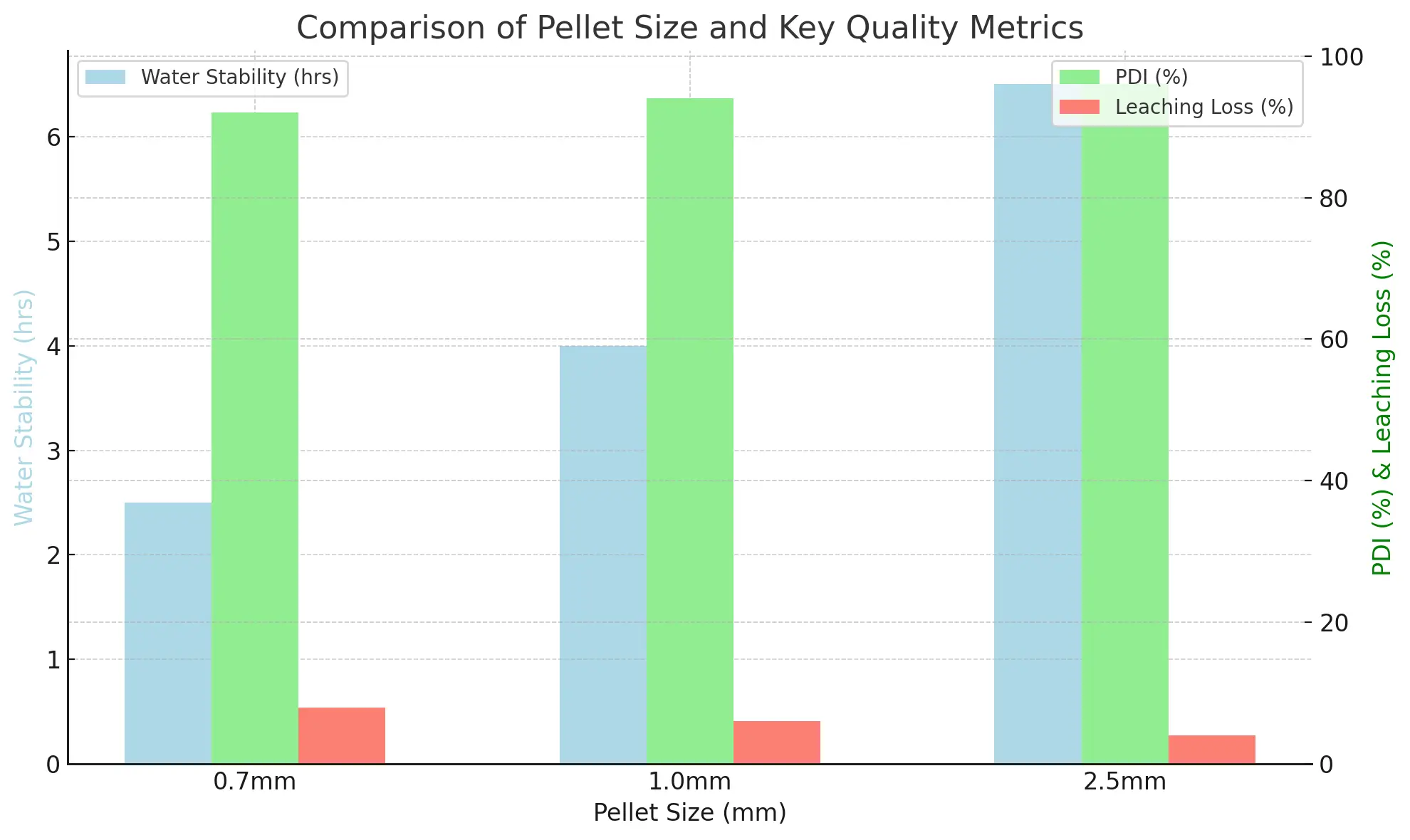

A key measure of pellet quality is the Pellet Durability Index (PDI). This index measures how well a pellet can stay intact during handling and transport.

For high-quality fish feed, the professional target is a PDI of 95% or higher. Achieving this ensures the pellet is strong and does not easily crumble into fine dust.

2: Water Stability & Leaching

The production line must be designed to produce pellets with a water stability of at least 1-2 hours. This is verified through a feed leaching test for sinking pellets to minimize nutrient loss.

3: Particle Size Distribution

Your design must accommodate different die sizes to produce the required pellet diameters for various fish species and their different growth stages.

Sectional Design: Key Considerations for an Efficient Flow

An efficient feed production line is a balanced system. Let’s look at the design considerations for each key section of the sinking fish feed pellet production process.

1. Raw Material Intake & Grinding Design Goal:

in order to attain a uniformly fine particle size. Technical Consideration: “Depending on your target species, you can choose between an ultra-fine pulverizer and a conventional hammer mill. An ultra-fine pulverizer is a crucial piece of equipment for sinking feed plants that process shrimp feed. This is due to its capacity to attain the necessary fineness for a robust, water-stable pellet.

2. Mixing & Conditioning: The Heart of Pellet Quality Design Goal:

To achieve a uniform mix and optimal steam conditioning. Technical Consideration: “The conditioner’s design is critical; a double layered conditioner is often preferred.

You need to ensure it provides a long enough retention time, often 60-90 seconds. It must also precisely control steam injection to raise the mash temperature to 80-95°C. This is key to activating sinking feed binder technologies.”

3. The Pelleting Section: Pellet Mill Efficiency Design Goal:

To maximize throughput and pellet density. Technical Consideration: ” For sinking feed, a ring die pellet machine is the standard and most cost-effective technology. This robust machine is designed for high-volume, industrial production.

Selecting the ideal die compression ratio is essential for feed quality. This represents the machine’s die’s hole’s length to diameter ratio. It regulates the amount of pressure that is put on the feed ingredients. For instance, a higher compression ratio is necessary for lighter, more fibrous materials to form a dense, hard pellet that will sink appropriately.

4. Drying & Cooling: The Energy and Stability Center Design Goal:

Gentle moisture removal and proper hardening of the pellets. Technical Consideration: “Controlling the temperature and time during the drying stage is critical for sinking feed. Drying the pellets too quickly or at too high a temperature can cause small cracks to form. These cracks will make the pellet unstable and cause it to fall apart in the water.

For this reason, a mesh type fish feed dryer is often a good choice. It allows for a longer and more gentle drying process. This method protects the pellet’s internal structure and is essential for achieving good water stability.”

Plant Layout & Scaling: From a Blueprint to a Business

A good physical layout and a smart plan for future growth are essential for the production process.

The Sinking Feed Plant Layout Design

An efficient production line layout is essential for two main reasons.

First, it is designed to minimize the travel distance for materials between each machine. This increases overall efficiency and reduces energy costs. Second, a proper layout prevents cross-contamination. This is critical for keeping raw ingredients separate from the finished product to ensure feed safety and quality.

The following flow chart shows a sample of an effective layout.

Planning for Utilities:

Power and Steam You must plan for the significant power and steam your plant will need.

| Capacity | Estimated Power (kW) | Estimated Steam (kg/hr) |

| 1 t/h Sinking Feed Plant | 150 – 200 kW | 250 – 300 kg/hr |

| 3 t/h Sinking Feed Plant | 300 – 400 kW | 700 – 800 kg/hr |

Scaling Your Line: Common Upgrade Paths

Scaling up your production is not just about getting bigger sinking fish feed pellet machines. The most common bottleneck that farmers face is the dryer. A smart scaling plan often involves upgrading your dryer and cooler before you upgrade your pellet mill to handle the increased capacity.

A Financial Perspective: Cost Per Ton and Investment Analysis

Estimating the Sinking Feed Line Cost Per Ton (OPEX)

A crucial part of your feed production cost analysis involves breaking down the operational costs: raw materials (like fishmeal, soybean meal, corn meal etc.), energy, labor, and maintenance.

The Initial Investment (CAPEX)

Investing in a sinking fish feed production line is a major financial decision. It is important to understand the costs involved.

A large portion of your budget goes toward the initial machinery cost for a high-quality 1 ton per hour (t/h) feed plant. Usually, this can fall between $30,000 and $50,000. This is frequently referred to as capital expenditure (CAPEX). Additionally, you need to budget for your operational expenditures (OPEX), which include the continuous costs of raw materials, labor, and energy.

The Importance of Installation and Commissioning

It is essential to budget for professional

installation and commissioning of sinking feed equipment.

This step ensures your sinking fish feed processing plant is set up correctly and runs efficiently from the very first day.

Common Design Flaws to Avoid

Design Flaw: “Under-sizing the Cooling and Screening System.”

An undersized cooler is a common cause of hot and dusty finished pellets. The pelletizing cooling step is critical for achieving a high sinking pellet hardness and a good PDI.

Design for Easy Cleaning and Maintenance

Construct access platforms around your conditioner and mixer. Easy access for comprehensive cleaning should be made possible by the conveyors’ design. Your team will actually perform easy maintenance if you design for it. This prolongs the life of your priceless equipment and avoids cross-contamination.

Invest in a Good Steam System.

The quality of your steam is directly correlated with the quality of your pellets. It is better to invest in a complete steam system rather than just a boiler. A top-notch system must have efficient steam traps and filters. This investment is justified by improved pellet durability and increased pellet mill efficiency.

Conclusion

It takes technical skill to design a sinking fish feed production line. It is focused on meeting important quality standards, such as PDI and water stability sinking pellet. A holistic approach is the key to success. This means that every machine is the right size and the whole system is built for quality control and efficiency, following the standards of the sinking feed industry.

FAQ About Sinking Fish Feed Production

Q: What’s the main technology difference between sinking fish feed manufacturing plant and floating feed plant?

A: The main difference from a floating feed production plant is the core shaping machine. Floating feed lines typically use an feed extruder. A sinking feed line uses pellet mills for high-pressure compression. In contrast, feed pellet production lines for floating fish feed use a more complex fish feed extruder machine (or pellet extruder) which cooks and expands the aquatic feed.

Q: What is a good Pellet Durability Index (PDI) for sinking fish feed?

A: For high-quality sinking fish feed production, you should target a PDI of 95% or higher. This indicates that the pellets are very durable and will not create a lot of dust during transport and feeding.

Q: How do I improve the water stability of my sinking pellets?

A: The three most important factors are: 1) a very fine grind of your raw material, 2) using an effective binder in your formulation, and 3) achieving excellent steam conditioning with the right temperature and moisture before the pellet mill.

Q: Who are the biggest energy consumers in a sinking fish feed production line?

A: The grinder (hammer mill) and the pellet mill itself are usually the two machines that use the most energy. The steam boiler also uses a lot of fuel. Making a cost-effective line is all about making sinking feed production more energy-efficient.

Q: Do I need a dryer for a sinking fish feed production line?

A: Yes, for sure. The steam conditioning process adds a lot of water. To make this water level safe for storage (usually 10–12%), you need to use a dryer. This is very important for keeping mold from growing and making sure your finished product lasts a long time.