| Price | 500-6000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Rabbit Feed Pellet Mill Overview

| Production Output | 0.1-2 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal/cake, edible leaf, fish meal, bone powder, etc |

| Type | flat die type |

| Final product size | 3-10 mm |

| Application | feed pellet producing, feed pellet industry |

| Used For | rabbit food production |

Electric vs Diesel rabbit feed pellet mill: Capacity & Energy

diesel engine rabbit pellet mill

| Model | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 4 | 50-80 | 100 |

| VTKLP-150 | 5 | 100-150 | 150 |

| VTKLP-210 | 10 | 200-400 | 260 |

| VTKLP-230 | 15 | 300-500 | 350 |

| VTKLP-260 | 20 | 500-700 | 420 |

| VTKLP-300 | 25 | 700-900 | 650 |

| VTKLP-360 | 30 | 900-1200 | 900 |

| VTKLP-400 | 40-50 | 1200-1500 | 1200 |

electric rabbit pellet mill

| Model | Electric Power(kw) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 3 | 50-80 | 80 |

| VTKLP-150 | 4 | 100-150 | 110 |

| VTKLP-210 | 7.5 | 200-400 | 210 |

| VTKLP-230 | 11 | 300-500 | 280 |

| VTKLP-260 | 15 | 500-700 | 300 |

| VTKLP-300 | 18.5 | 700-900 | 500 |

| VTKLP-360 | 22 | 900-1200 | 700 |

| VTKLP-400 | 30-37 | 1200-1500 | 900 |

Rabbit Feed Production video: 3mm Pellet

rabbit pellet mill: Multi-Species Feed Solution

Modern rabbit feed pellet mill deliver perfectly balanced meals for bunnies. Farmers using these systems see rabbits grow 30% quicker. Plus, the uniform pellets prevent tummy troubles – no more selective feeding! The rabbit feed pellet making machine can solve a common problem: making sure rabbits get the same healthy food mix every time.

With rabbit farming growing fast, rabbit pellet maker can save your time and money. Farmers can use them to make food for pigs, sheep, chickens and bunny all at once.

Rabbits need a lot of food daily. Some farmers buy pellets from feed plants, some make their own. Buying a rabbit feed pellet mill raises questions – especially for new users – because people have different needs.

Industrial-Grade Rabbit Pellet Mill

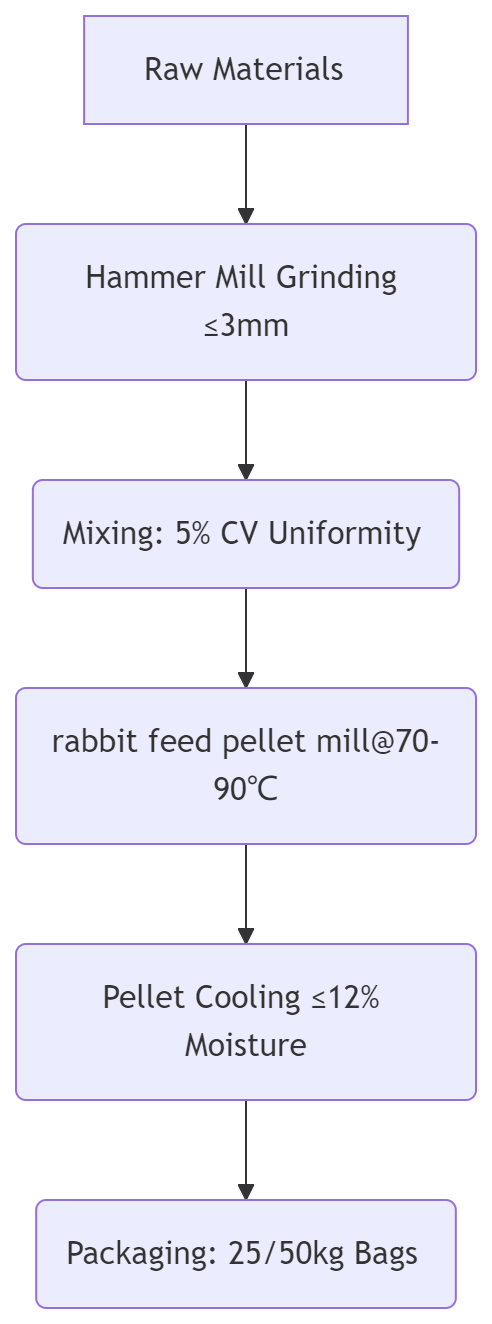

A specialized feed processing system combining grinding (≤3mm particle size), mixing (CV≤7%), and pelleting (70-100℃ thermal treatment) to produce nutritionally balanced bunny food with 12-18% moisture content.

Nutrition Science: 92% Protein Retention & 99.9% Pathogen Elimination

Rabbit feed pellet making machine create food full of key vitamins and minerals for growing rabbits. Most eat about 1 ounce of pellets per pound of body weight. Rabbit pellets are still called the base of a rabbit’s diet.

But truth is, feed pellets work best for young rabbits, not adults. Why? They’re loaded with nutrients that help baby rabbits grow right.

When rabbits grow up, you should give them fewer pellets. you should add more hay, veggies, or fresh grass in their food. This can help to prevent them from too heavy or sickness. Rabbits need the right mixtures of foods to get stronger and healthier.

Rabbit pellets are made with good stuff like alfalfa, grains, and vitamins. These are good for young and adult rabbits. These food can stay fresh longer and are simple to keep. That’s why many rabbit owners choose pellets.

Now, let’s look at why pellets help raise healthy rabbits and how rabbit feed pellet machine make them.

Scientific Nutrition Assurance

| Parameter | Standard | Impact |

|---|---|---|

| Protein Retention | 92% ±2% | Optimal muscle development |

| Vitamin Stability | 85% post-processing | Enhanced immune function |

| Pellet Durability | ≥95% PDIndex | Reduced feed waste |

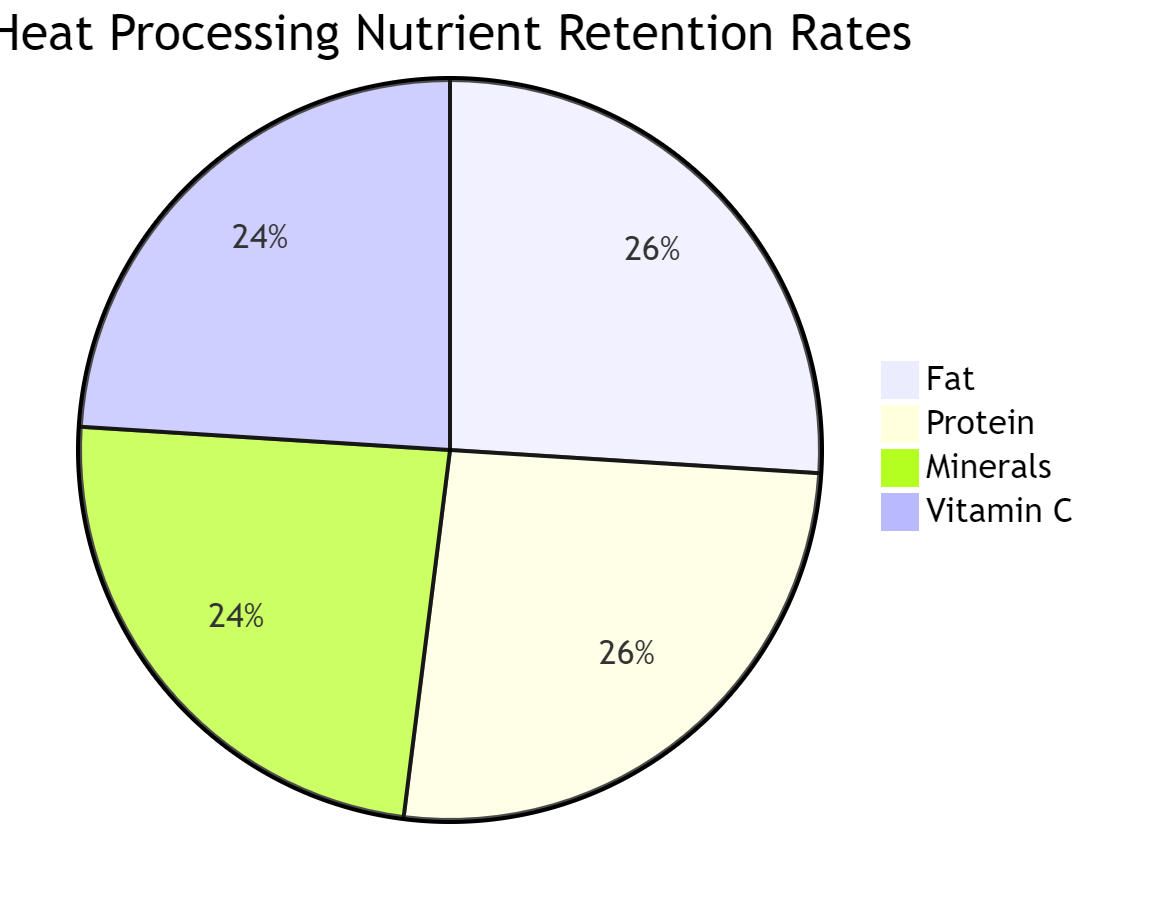

Enhanced Nutritional Data Visualization

good pellet palatability

when you make bunny food, there is a special starch paste step. This step mainly does two main things: 1. making bunny food a yummy taste 2. Making rabbits to want to eat more. Testing shows that this method can improve food taste by 10% to 15%.

proper pellets rigidity

Good pellet hardness. Unlike wet mix powder, feed pellets are much harder – perfect for rabbits’ natural need to grind teeth on hard objects. This matches their chewing habits better than soft foods.

sterilization and digestion

this step can prevent diet problems from picky eating. it can make bunny food easier to digest, and boosts nutrient digestion in their gut. it is just like a special helper that can make your bunnies much healthier from nose to tail!

feed digestion rate

Heat cleaning cuts disease risks. When making feed pellets, the pressing process heats them to 70°C-100°C fast. This hot treatment zaps parasite eggs and harmful germs dead.

Temperature Parameter Validation

| Temperature Range | Vitamin C Retention Rate | Starch Gelatinization Rate | Pathogen Elimination Rate |

|---|---|---|---|

| 70-75℃ | 98% | 82% | 95% |

| 80-85℃ | 94% | 89% | 99% |

| 86-90℃ | 89% | 93% | 99.9% |

Rabbit Feed Production Process Flowchart

23% Global Rabbit Meat Growth & 15-20% FCR Boost

Key Market Driver:

Global rabbit meat production grew 23% since 2018 (FAO 2023), driving demand for automated feed solutions that improve feed conversion rates (FCR) by 15-20%.

Improve immunity:

Rabbit feed pellet making machine makes pellets with rich nutrition. The pellets mix all the good stuff that bunny need evenly. This perfect mixture helps to prevent diseases and keeps bunnies much healthier and stronger.

Cost-effectiveness:

Turning powder feed into small pellets are benefits in three ways. First, it makes packing simpler. Second, storing takes less space. Third, moving becomes easier. All these benefits can save money for farmers and feed plant.

Increased growth:

The factory can cook the feed pellets in a just right way. This makes pellet food easier for bunny to digest. It also helps them to grow much stronger and stay much healthier.

Rabbits get fresh feed:

Running a rabbit farm gets easier with a rabbit feed pellet mill. This rabbit feed pellet making machine lets farmers mix just the right stuff in the food and keep every meal fresh for the bunnies.

Avoid picky eaters:

The rabbit feed pellet mill mixes different foods together. This stops picky eating and makes sure bunny get all the nutrients they need. The machine also creates strong, top-quality pellets every time.

7-Day Transition Protocol: Avoiding Digestive Stress in Rabbits

it is better always to use the rabbit feed pellet mill from the same brand after you choose your pellets. Rabbits can get upset tummies if their food changes too fast. When switching foods, mixing old and new pellets together so their stomachs can adjust.

Keeping enough old food to make the change slowly over 7 days or more. For best results, try to use a small electric rabbit feed pelletizer mill. It makes your own pellets easy and saves you money over time.

Keep pellets in sealed containers where it’s cool and dry. This keeps them clean and safe from dust and sunlight. Always close the lid tight to stop germs. Never mix regular food with pellets – bunnies might pick favorites and skip healthy stuff.

Give just enough food. Heavy rabbits live shorter lives. Feed 1/8 cup of healthy pellets daily for every 4 pounds of bunny weight. Baby bunnies can eat freely until 8 months old, then switch to smaller amounts.