| Price | 500-5000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

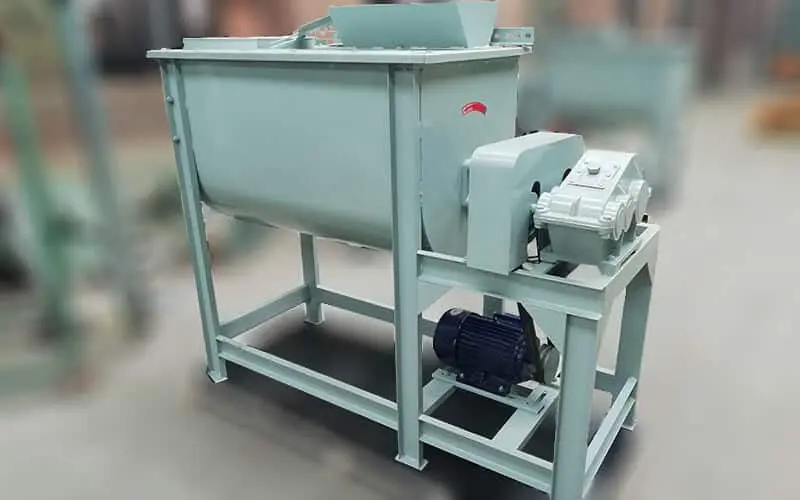

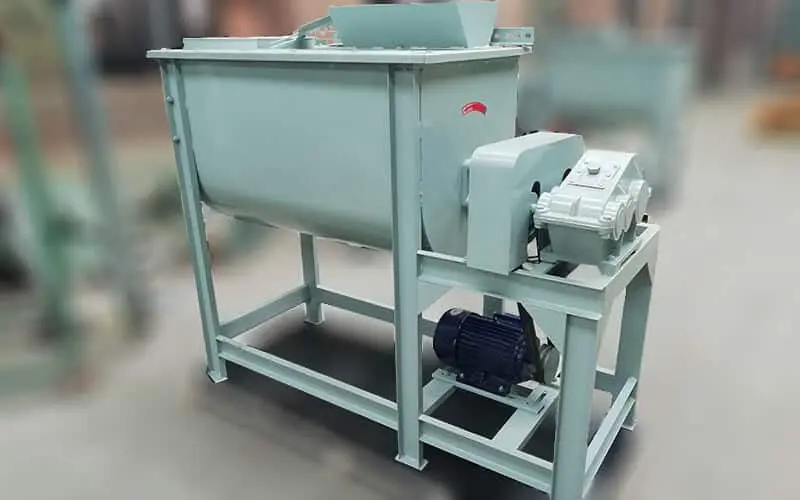

VTHS Feed Mixer Specifications and Features

| Production Output | 0.1-5 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal/cake, edible leaf, fish meal, bone powder, etc |

| Type | Horizontal Ribbon |

| Final product size | finest powder |

| Application | mixing powder materials |

| Used For | animal and livestock feed mixing |

animal Feed Mixer Capacity and power

electric

| Model | Electric Power(kw) | Output(kg/h) |

| VTHS-100 | 3 | 100-300 |

| VTHS-150 | 4 | 150-450 |

| VTHS-250 | 5.5 | 200-800 |

| VTHS-500 | 7.5 | 1000-1500 |

| VTHS-1000 | 15 | 1500-3000 |

| VTHS-2000 | 18.5 | 2000-5000 |

diesel engine

| Model | Diesel Engine Power(HP) | Output(kg/h) |

| VTHS-100 | 4 | 100-300 |

| VTHS-150 | 5 | 150-450 |

| VTHS-250 | 7 | 200-800 |

| VTHS-500 | 10 | 1000-1500 |

| VTHS-1000 | 20 | 1500-3000 |

| VTHS-2000 | 25 | 2000-5000 |

animal feed mixing process video

what is Animal feed mixer machine?

The animal feed mixer machine mixes powder materials very well. They are very important for making high-quality animal food, such as mixing feed for cattle, pigs, sheep, goats, rabbits, and other livestock. Good mixing makes sure that nutrients are spread evenly when you make pellet food or mash feed. This is good for the animals and saves you time.

Cleaning Your Mixer the Right Way

To keep the animal feed mixing machine working well, you should always clean it after using it. Animals can get sick and weak if they eat bad food. Mixers can be either up-down or side-by-side. We use the kind that goes side by side. Its spinning blades mix dry and wet food for animals like cows, pigs, and goats.

How Mixers Keep Food Consistent

This keeps meals fair so that all animals get what they need. Cleaning the animal feed blender machine once a week can keep food from sticking. This blender is very important for making food for animals and fish.

Choosing Your Mixer Size & Power

It can make between 100 and 5000 kilograms of feed every hour. There are two sizes: small and large. Small ones can make between 100 and 800 kg every hour. Some weigh one or two tons. The machine that mixes animal feed can run on either electricity or diesel. People choose the size that works best for their farm.

This mixer mixes vitamins with grain powder to make food for animals. It also works well for raising pigs, cows, and other animals. This blender can help people get strong animals and save money. Check the mix every hour to make sure all the pieces are the same.

electric

diesel engine

Mixers for All Animal Feed Types

The animal feed mixer machine can mix food for cows, pigs, sheep, goats, and other farm animals. It mixes together things like plant food, animal pills, and chemicals used on farms. It comes in two strong types: regular steel that won’t rust or tough steel.

Why Mixer Materials Matter

Both machines can keep the mixtures clean and safe for years. Farmers can save time by using just one machine for many tasks. There are three main parts to this feed mixer: a big bowl, twisting arms, and a motor.

How Mixer Arms Work Together

The arms of the mixer are like magic hands. The big arm moves food from the sides to the middle. The small arm pushes it back out. This push-pull game mixes all the pieces together perfectly. You need this tool to make perfect forage balls out of grains.

Working Principle and Operational Flow

There are two smart parts to this animal feed mixer machine: a U-shaped tub and a special mixing belt. The arms of the mixer spin in the curved tub, which has little room on all sides. This high-tech design makes sure that every piece gets the right amount of mixture and that it is evenly distributed.

Farmers get even faster blending and save money on feed. This animal feed mixer machine has advanced ribbons that move like dance partners. The outer blade spins in the opposite direction from the inner blade.

They push and pull bits of forage through the whole tub. The outer blade pushes food to the middle so that it is easy to empty. It also lifts food up the walls to mix everything together. Farmers can make perfect blends in half the time.

Key Features

It mixes grain powders into nutritional food ideal for cattle, pig, goat, rabbit, and other livestock fodder.

This animal feed mixer machine offers high efficiency, reliable operation, and a small footprint, ideal for small workshop forage pellet plants.

The mixing time of each batch is short. 500-4000kg fodder powder for 3-6 minutes.

Smooth transmission and low wear. Three materials are available for you to choose from: stainless steel, carbon steel and composite.

The optimized bidirectional rotating wheel makes the mixing effect fully uniform, CV≤5%.

The mixing effect is not affected by the fitness and density of the powder. Ribbon mixers are also suitable for viscous materials.

It mixes dry powder materials and healthy bits for animal food. You can use it for thick liquids and sticky stuff like dough. Even small grains mix well in it. farmers can use this food mixing equipment to make all fodder types and save time and money.

Maintenance Guide: Energy Efficiency Best Practices

Maintenance Schedule and Procedures

The mixing chamber should be cleaned after each use. If the blender is out of use for a long time, we should clean it thoroughly and cover it.

Make sure the electrical control parts of the food mixing machine are clean and flexible. If the machine fails, it should be repaired in time.

Check the equipment parts regularly once or twice a month. Pay special attention to the power shaft, transmission components and reducer housing.

The retarder oil should be kept clean. If the equipment is used frequently, we should change the oil every three months.

Place the animal feed mixer in a ventilated, dry and clean room. The feed mixing machine can work perfectly in the temperature ranging from -5°C to 40°C.

Safe Operation Protocols

Turn on the power and the equipment starts to work. If the equipment has any abnormal noise or vibration, we should immediately shut down the equipment and check it.

Check the machine before starting operation. Make sure there are no foreign objects in the blender and the inner walls are dry and clean.

Check the food ingredients to make sure they are completely dry.

Prepare a container under the outlet of the equipment. When the mixer has finished mixing, we can discharge the material into the container.

Put the ingredients into the equipment according to the capacity of the blender. Then screw the cap on the inlet.

Feed Mixing Uniformity Impact on Livestock ROI

This machine mixes all the food parts and vitamin packs together so that every bite has the same good stuff. It spreads all the good things evenly. Animals get everything they need to grow strong in the last mix. Imagine making the best meals for cows, pigs, and rabbits.

To keep the magic working right, clean the animal feed mixer after each batch. Farmers save money on vet visits and have healthier animals. When making food for animals, the most important thing is to mix it better. It makes sure that every bite has the same good parts.

This stops bad mixing that makes some parts worse than others. Animals can get weak and sick if they don’t get good food or if they mix it poorly. When this happens, farmers lose money. It’s like making a cake where all the parts have to mix together just right.

For Mixing Cattle Feed

The main reason for mixing cattle feed is to make sure that all of the ingredients are well-mixed. This includes grains, forages, and extra food. A consistent cattle feed blender is important because it stops animals from only eating certain things. This can make the rumen more stable and may increase milk production by 3–5%.

To get this even mix, you need a good cattle feed mixer machine. The cattle feed mixing machine is built to mix a lot of different kinds of materials. This lets farmers give each animal a perfectly balanced meal every time. This helps the herd stay healthy and do well.

For Mixing Pig Feed

There is a specific problem with mixing pig feed. This is because the formulas usually have both fine powders and liquids that stick together, like molasses. A good pig feed mixer machine is made to meet these needs. The main goal is to make a mix that is very even.

This makes sure that important micro-ingredients are evenly spread throughout the batch. A good pig feed mixing machine usually has a lot of spray nozzles. This lets you add 3–8% liquid evenly without making clumps. This step is very important for making a full, tasty, and consistent ration for your herd.