| Price | 5000-60000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Product Overview

| Production Output | 400–800bags/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | powder materials, grains, pellets, fish feed, animal feed, poultry feed, fertilizer, etc |

| Type | automatic weighing and packing |

| Accuracy | ±0.2%–0.5% |

| Packing Range | 25–50kg/bag |

| Sewing Device | Automatic sewing and transporting |

| Weighing Device | automatic weighing with computer |

specification

| Model | DCS50 |

| Power | Main power:0.55kw sewing power:0.37kw transport power:0.37kw |

| Packing capacity | 400–800bags/h |

| Accuracy | ±0.2%–0.5% |

| Packing range | 25–50kg/bag |

| Bags materials | Woven bag,cloth bag,plastic bag,sacks bag,etc |

| Packing materials range | Grain,seeds,fertilizer,feeds,chemical materials,powder etc |

| Sewing device | Automatic sewing and transporting |

| weighing device | automatic weighing with computer |

| Size | 3000*900*2700mm |

| Weight | 260kg |

working video

what is automatic packaging machine?

The fully automatic packing machine, with advanced computer control, automates bag packing, mainly for weighing and packing feed pellets to save labor. It often integrates with conveyor belts and sewing machines for an automatic feed pellet weighing and packing system in feed production.

As the name suggests, automatic packing machines are specially for products such as fish feed pellets, organic fertilizers, compound fertilizers, white sugar, seeds, grains, wood pellet and other animal feed pellets.

In large-volume fish feed production, fish feed extruders work continuously. Improper storage of small fish feed pellets can degrade quality and nutrition. A cost-effective industrial automatic bagging machine that protects fish feed from contamination during transportation and sale.

It can realize the standardization of packaging, greatly reduce labor costs, and meet the requirements of large-scale production. All these features make the fish feed packaging machine an indispensable part of a fish feed production line.

appication

The automatic pellet weighing and packing machine is suitable for large and medium-sized feed pellet production plant. Feed pellet packing machine have been used in automatic weighing and packing systems, combined with transport mechanisms and sewing machines.

The automatic bagging machine suits feed, sawdust pellets, grain, fertilizer, and materials with good fluidity. Many large-scale feed plants adopt it for its excellent performance.

features of automatic packaging machine

The automatic bagging machine has the advantages of high calculation accuracy, stable function, digital demonstration, and convenient operation.

The feed pellet weighing and packing machine is equipped with computer control software, which can set control data, automatically repair the drop, and automatically detect faults.

The special anti-seismic equipment for the automatic bagging machine ensures accurate calculation, fast speed and stable operation under harsh conditions. It can be adjusted outdoors for easy maintenance.

Adopt double scale working system. The two scales can work synchronously or individually, which improves the work efficiency of the feed pellet automatic packaging machine.

This feed pellet packing machine has a three-speed feeding system, which ensures the weighing speed and weighing accuracy.

Using internationally advanced sensors and pneumatic actuators, the feed pellet automatic packaging machine works reliably and without pollution.

The outer surface adopts plastic spraying process, and the inner surface adopts advanced stainless steel material, which is anti-rust and anti-corrosion, which prolongs the service life of the automatic machine.

The weighing and bagging machine for feed pellets reserves a communication interface, and the whole automatic packaging machine can realize digital connection with the upper computer on the feed pellet production line.

Computer high-speed feeding and sampling processing, programmable control process, to ensure the versatility of different packaging.

The belt feeder of this automatic pellet bagging machine with a single weigh hopper provides a complete bagging and packing arrangement. Automatic packaging machine are available in various sizes.

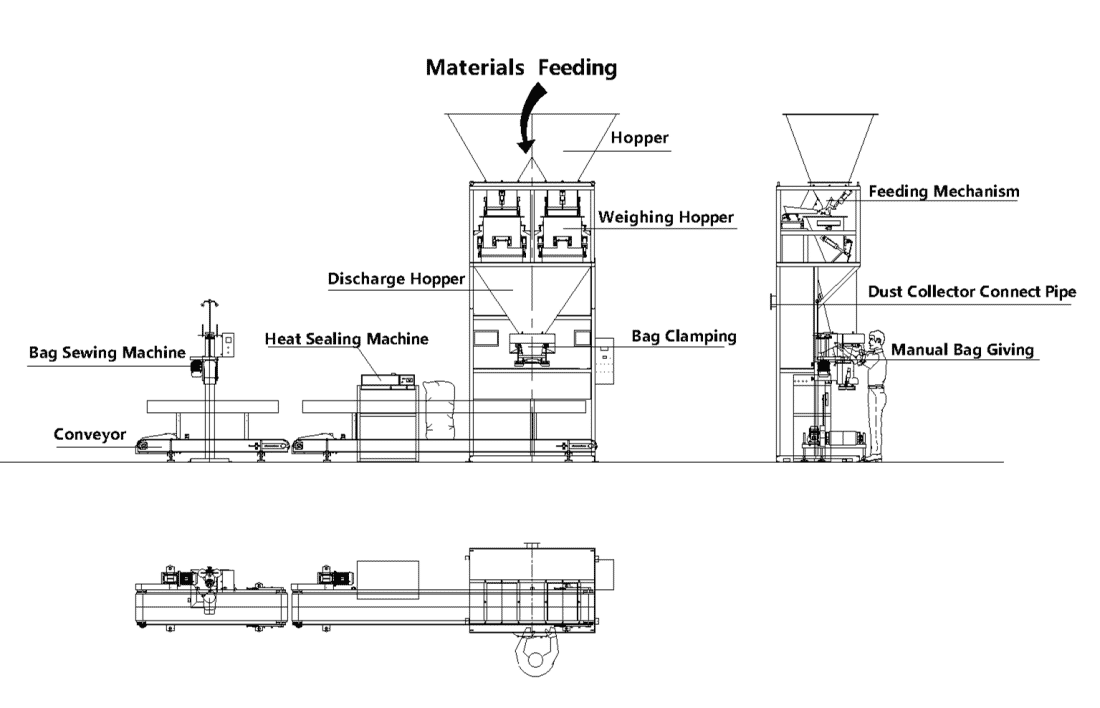

structure of automatic packaging machine

The automatic packing machine includes an automatic packing device, weighing device, transmission device, sewing device, and electric control system. The automatic weighing device is designed with two separate weighings.

They can work together or separate during the weighing process. Once one of the scales fails, the other will work continuously to avoid production downtime. After the feed pellets are weighed and poured into the bag, the bag is sealed using a sewing device.

The transfer device can transfer the packaged pellet bags from the automatic packing machine. All these steps are under the control of the electronic control system. The feed pellet bagging machine is reliable and efficient, serving wood pellet factories, feed lines, the sugar industry, and others.