| Price | 500-8000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Product Overview

| Production Output | 0.1-5 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn meal, wheat, barley flour, soybean meal, oil seed meal, fish meal, bone meal, etc |

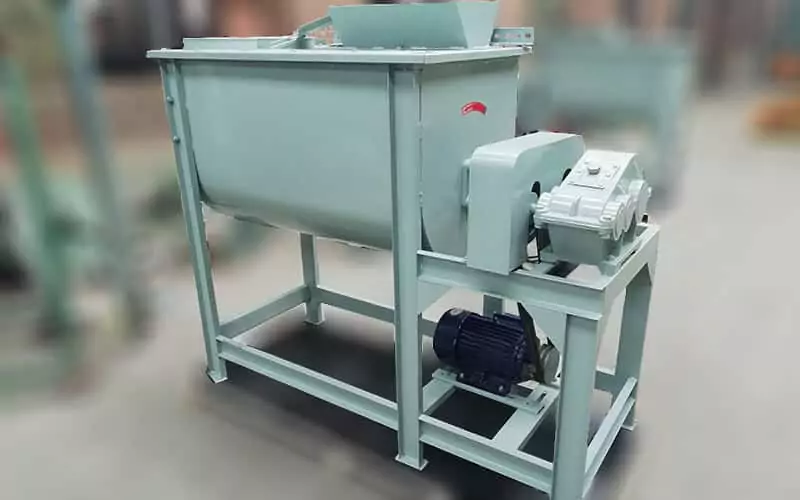

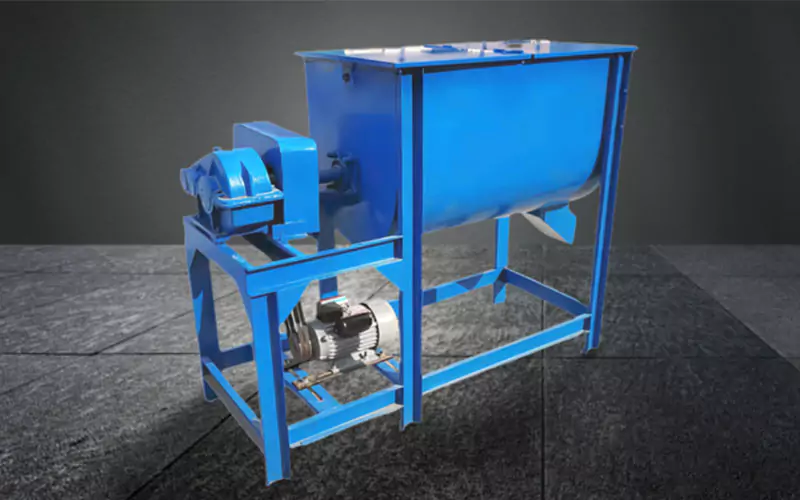

| Type | Horizontal Ribbon |

| Final product size | 0.4-10 mm |

| Application | mixing powder materials |

| Used For | cattle feed production |

specification of Cattle feed mixer machine

electric power type

| Model | Electric Power(kw) | Output(kg/h) |

| VTHS-100 | 3 | 100-300 |

| VTHS-150 | 4 | 150-450 |

| VTHS-250 | 5.5 | 200-800 |

| VTHS-500 | 7.5 | 1000-1500 |

| VTHS-1000 | 15 | 1500-3000 |

| VTHS-2000 | 18.5 | 2000-5000 |

diesel engine type

| Model | Diesel Engine Power(HP) | Output(kg/h) |

| VTHS-100 | 4 | 100-300 |

| VTHS-150 | 5 | 150-450 |

| VTHS-250 | 7 | 200-800 |

| VTHS-500 | 10 | 1000-1500 |

| VTHS-1000 | 20 | 1500-3000 |

| VTHS-2000 | 25 | 2000-5000 |

Introduction of Cattle Feed Mixing Machine

You know a cattle feed mixer is key to preventing feed sorting and boosting your herd’s performance. But not all mixers are created equal. The critical question for a professional operation is: which cattle feed mixing technology can consistently achieve a mixing uniformity (CV) of less than 5% in a short, efficient mixing time?

We will analyze the performance, advantages, and disadvantages of the three main mixer types: vertical, horizontal, and twin-shaft paddle mixers. You can check our specially horizontal feed mixing machine here.

What a Mixing CV of ≤5% Means for Your Herd

Before we compare the machines, we must first understand the goal.

- The Science of Mixing Uniformity (CV) The mixing coefficient of variation (CV) is a statistical measure of how evenly your micro-ingredients are distributed throughout the feed. A CV of ≤5% is the industry gold standard for a high-performance cattle feed mixer. It means that every mouthful of feed a cow eats is virtually identical in nutritional content.

- The Impact on Herd Performance Achieving this low CV is critical. A consistent ration stabilizes the cow’s rumen health. This can improve milk yield by 3-5% and significantly improve the average daily gain in beef cattle. It ensures every animal gets the precise nutrition you have formulated.

Vertical vs. Horizontal vs. Twin-Shaft Mixers

Each mixer type uses a different technology to achieve a uniform mix. Choosing the right one depends on your specific needs.

1. The Vertical Auger Mixer How it works:

These mixers have one or more large, vertical screws (augers) in a tub. The augers lift ingredients from the bottom and circulate them up and around. They are very good at processing large round or square bales of hay.

Performance Analysis:

A vertical mixer typically requires a longer mixing time to achieve a low CV, often 6–10 minutes, especially with dry hay. It is an excellent choice for many beef cattle and dry cow rations where processing whole bales is a priority. However, it can struggle with small batches (less than 50% capacity) and may be less precise for complex dairy rations.

2. The Horizontal Auger/Reel Mixer How it works:

These use horizontal augers (screws) or a large reel inside a long trough to tumble and mix the feed. They are often known for mixing very quickly.

Performance Analysis:

They are faster than vertical mixers and can typically achieve a low CV in 4–6 minutes. They are a popular choice for high-performance dairy rations where consistency is the top priority. Their main limitation is that they are not as effective at processing whole, unprocessed hay bales.

3. The Twin-Shaft Paddle Mixer How it works:

This mixer uses two intermeshing shafts of paddles. These paddles provide a gentle, lifting, and folding action.

Performance Analysis:

This type is often the fastest, achieving a low CV in as little as 3–5 minutes. The mixing action is very thorough and gentle on feed particles. This makes it the superior choice for precision mixing of complex rations, including those with sticky ingredients like molasses or liquid supplements. Its main limitation is its high initial cost.

Performance Comparison Table

| Mixer Type | Typical Time to CV ≤5% | Hay Bale Processing | Mixing Precision | Initial Cost |

| Vertical Auger | 6 – 10 min | Excellent | Good | Medium |

| Horizontal Auger | 4 – 6 min | Poor to Fair | Excellent | Medium-High |

| Twin-Shaft Paddle | 3 – 5 min | Poor | Superior | High |

Key Technical Specifications to Compare Before You Buy

When you are comparing mixers, look beyond the price and consider these technical details.

The Weighing System (Load Cells)

The accuracy of your entire ration depends on the load cell weighing system. A high-quality system should have at least 3-4 high-quality load cells. You should also demand a calibration certificate from the manufacturer.

Construction & Wear Resistance

A key detail to check is the thickness of the steel. For a heavy-duty mixer, look for a wear-resistant liner of at least 6–8 mm at the bottom of the tub. This is often made from a special hardened steel.

Power Requirements (kW) & Drivetrain

Understand the power needs for different sizes (5 m³, 10 m³, etc.). Also consider the pros and cons of PTO vs. electric vs. diesel drive for your specific farm setup.

Automation & Control (PLC/HMI)

For large operations, a PLC control system with an HMI panel can automate your loading and mixing sequences. This improves accuracy and reduces labor.

Checklist for Choosing the Right Cattle Feed Mixer

What’s Your Herd Size?

This data is used to determine the required mixer capacity, which is typically measured in cubic meters (m³).

What Are Your Main Ingredients?

The primary composition of your feed ration is a critical factor when choosing between a vertical and a horizontal mixer. Rations consisting mainly of wet silage and grains require a different mixing technology than those that must process large, dry hay bales. You can check our cattle feed formulation and ingredients.

What is Your Power Source?

Most large cattle feed mixers are driven by a tractor’s PTO (Power Take-Off). Smaller stationary mixers can be electric, but you will need the right kind of power supply for them.

Look for Durability

Cattle feed mixers are required to perform heavy-duty work on a daily basis, so build quality is a primary consideration. It is advisable to select a machine with robust steel construction, heavy-duty augers, and a reliable drive system. For mixing chicken feed, you can check our chicken feed mixer machine.

A Financial Perspective: The Cost and ROI of Precision Mixing

Getting a great mix every time takes a little know-how. Here are some tips from experience:

The Initial Investment (CAPEX)

The cattle feed mixer price is a significant investment. A high-quality 10 m³ cattle feed mixer wagon price can range widely depending on the technology. A vertical cattle feed mixer price is often the entry point, while a twin-shaft paddle feed mixer price will be at the premium end of the market.

The Return on Investment (ROI)

Your ROI doesn’t come from the machine itself; it comes from the improved performance of your herd. By reducing feed sorting and ensuring a consistent ration, a good mixer can lead to a measurable improvement in milk yield or daily weight gain. This is how the machine pays for itself over time.

Conclusion

Choosing the right cattle feed mixer is a technical decision. While a vertical mixer is a versatile workhorse for many farms, a horizontal or twin-shaft paddle mixer can achieve a superior mixing uniformity (CV ≤5%) in a shorter amount of time.

The best machine for you depends on your specific ingredients, your herd’s nutritional needs, and your budget. Investing in a machine that can deliver a precise, uniform cattle feed mixer is a direct investment in the health and profitability of your cattle operation. If you want to make pellet feed, you can check our how to make cattle feed.

FAQ About Cattle Feed Mixing Machine

1) Which mixer type most reliably achieves CV ≤5% for powders?

Answer:

- Twin-shaft paddle: Broadest applicability for powders; gentle shear; typically 2–4 min to CV ≤5–7%; best when formulas change often or need liquid addition.

- Horizontal ribbon/auger: Cost-effective for homogeneous powders (small PSD/ density spread); 3–6 min to CV ≤5–7%; more sensitive to large particle/ density differences.

- Vertical: Simple and low cost; often 6–10 min to approach CV ≤7–10%; less friendly to small batches and frequent changeovers. If you have micro-additives (<0.5%) or need in-mixer liquid dosing, prioritize twin-shaft paddle.

2) How do we verify CV ≤5%? (quick SOP)

Answer:

- Tracer: Salt/iron oxide/premix (as per formula).

- Sampling: ≥10 grabs per batch (top/middle/bottom + near discharge), sealed immediately.

- Calculation: CV% = (SD / Mean) × 100. Targets: ≤5% (excellent), ≤7% (acceptable).

- Frequency: New formula, batch-size change, post-maintenance, then weekly spot checks.

- Controls: Calibrated balances; consistent assay method; avoid sample moisture uptake.

3) What’s the safe upper limit for in-mixer liquid addition to powders?

Answer:

- Typical ceiling: ≤3–5% w/w without clumping (higher requires staged dosing or vacuum coating downstream).

- Method: Dry-mix → atomized spray via multi-nozzle lance (droplet size < dominant particle) → post-mix 30–60 s.

- Keys: Multi-point spray coverage, avoid dead zones, control product & room RH/temperature to prevent caking/bridging.