| Price | 500-6000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

VTKLP Alfalfa Pellet Press: 0.1-2T/H & Dual-Power (Electric/Diesel)

| Production Output | 0.1-2 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | grass, hay, alfalfa, straw, cereal, corn, wheat, barley flour, soybean, oil seed meal/cake, edible leaf, fish meal, bone powder, etc |

| Type | flat die type |

| Final product size | 3-10 mm |

| Application | feed pellet producing, feed pellet industry |

| Used For | animal feed production, alfalfa pellet production, fuel pellet production |

Electric vs Diesel Models: 50-1500kg/h Output & Energy Cost Comparison

electric motor

| Model | Electric Power(kw) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 3 | 50-80 | 80 |

| VTKLP-150 | 4 | 100-150 | 110 |

| VTKLP-210 | 7.5 | 200-400 | 210 |

| VTKLP-230 | 11 | 300-500 | 280 |

| VTKLP-260 | 15 | 500-700 | 300 |

| VTKLP-300 | 18.5 | 700-900 | 500 |

| VTKLP-360 | 22 | 900-1200 | 700 |

| VTKLP-400 | 30-37 | 1200-1500 | 900 |

diesel engine

| Model | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 4 | 50-80 | 100 |

| VTKLP-150 | 5 | 100-150 | 150 |

| VTKLP-210 | 10 | 200-400 | 260 |

| VTKLP-230 | 15 | 300-500 | 350 |

| VTKLP-260 | 20 | 500-700 | 420 |

| VTKLP-300 | 25 | 700-900 | 650 |

| VTKLP-360 | 30 | 900-1200 | 900 |

| VTKLP-400 | 40-50 | 1200-1500 | 1200 |

Multi-Functional Pelletizing: Feed Production & Biomass Fuel Solutions

The alfalfa pellet machine makes small feed and fuel pellets from alfalfa. The pellets are 2mm to 8mm in size. Our factory builds two types of machines: electric ones and diesel ones.

They are made for medicago sativa farmers. These alfalfa pellet making machine cost little money but help farmers make fuel pellets. This cuts farm costs. The machines can also use hay, grass, or straw to make pellets for feed and fuel.

Nitrogen Fixation & Protein Feed Pellets

Alfalfa’s Dual Role in Soil Enrichment & Fuel Production

Lucerne grows all year and lives 4 to 20 years. It is one of the best crops that add natural nitrogen to soil. Lucerne makes top-quality fuel pellets for heating. These pellets need no extra nitrogen fertilizers.

The Ultimate Animal Feed Superfood

Alfalfa is called the king of animal feed. It grows a lot, has top quality, and is full of good nutrients. Lucerne gives animals crude protein, energy foods, and vitamins B, C, and E. Most farm animals love eating it.

Modern Alfalfa Pellet Production Techniques

more and more people plant Lucerne at now as the trade is booming. people dry Lucerne and press it into small pellets with alfalfa pellet mill. These protein-rich pellets let farmers use less other feeds. They are simpler to feed to animals, easily move around, and store than fresh alfalfa.

Alfalfa’s Agricultural Resilience & Nutritional Value

Lucerne is a strong plant that grows back yearly. It can live in most weather and dirt types. Farmers call it the best food for farm animals because it grows lots, tastes good, and feeds well.

The Lucerne stems and leaves have crude protein, good fiber, and key minerals. It also gives animals vitamins and carotenoids. Research shows it works well as feed for cows, sheep, pigs, chickens, rabbits, horses, and camels.

Optimizing Feed with Alfalfa Pellet Machine

if you want to make feed, and easy to move, store and save you money, you can put the dried lucerne through a alfalfa pellet machine. The machine breaks open the plant’s tough fibers. This softens the hard parts so animals can digest it better.

what alfalfa pellets used for?

The lucerne pellets add healthy energy to horse feed. Made from plants, they give horses good energy without the risks of sugary grain feeds.

These plant-based calories don’t cause the problems that come from sugary grain feeds. They give steady energy without making horses too wild. Most horses stay calm when eating feed pellets.

for animal feed

make great animal feed. When compared to straw feed, lucerne pellets stay clean. They also have a good mix of nutrients, can be stored easily, and last longer.

for animal bedding

work not just as fuel or animal food. They also make safe bedding for animals like horses and cats. These pellets have no added chemicals.

for heating fuel

work well as fuel for home heating systems like pellet boilers and stoves. Bigger lucerne pellets can be mixed and burned with coal in heating machines.

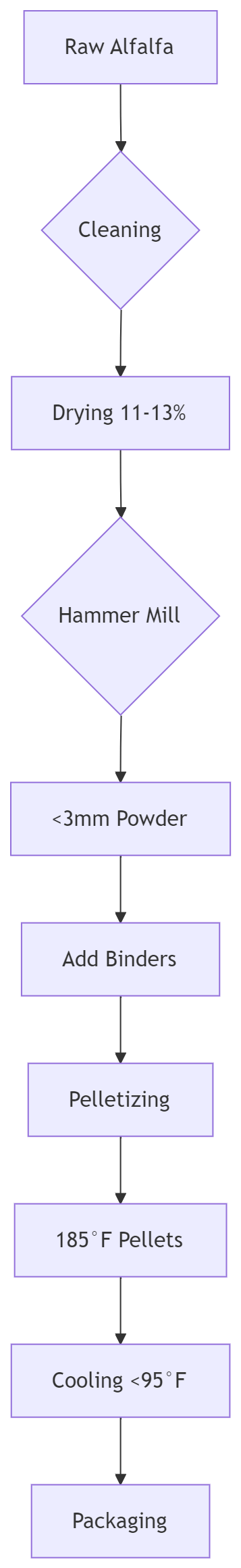

how to make alfalfa pellets for feed and fuel?

The alfalfa pellet machine is a special type of pellet press. It makes small alfalfa pellets. Farmers often use these pellets to feed cows, help plants grow, or burn for heat. Many see them as good fuel pellets that work well in heaters.

① Preprocessing

you need to clean alfalfa at first before using the alfalfa pellet mill. Lucerne often has more dirt and bits than wood shavings. you need always to check and remove any unwanted stuff to keep the alfalfa pellet machine running smoothly.

② Drying (optional)

if you want to make top-quality lucerne pellets, you need to keep the moisture percentage right when making them. The best water amount is 11% to 13%. Use a drying machine to reduce the water percentage fast. Or spread it in sunlight to dry naturally.

③ Crushing

Fresh lucerne hay is too big for alfalfa pellet machine. firstly crush it into small pieces using a grinder mill. This makes the pellet-making work better and gives stronger pellets. A hammer mill can break the hay into different sizes for your needs.

④ pelleting

put lucerne powder into the pellet machine. The machine squeezes it into small pellets. Adding sticky stuff like 1-3% molasses, fat, or clay helps hold the pellets stronger together. When done, you can get clean alfalfa feed pellets ready to use.

Alfalfa Pellet Production Workflow