what is dry type fish feed extruder?

Two fish feed machines, dry and wet type extruders, produce floating feed. The dry type makes feed for fish, tilapia, catfish, shrimp, crab, turtle, and goldfish. It extrudes pellets at high temperature.

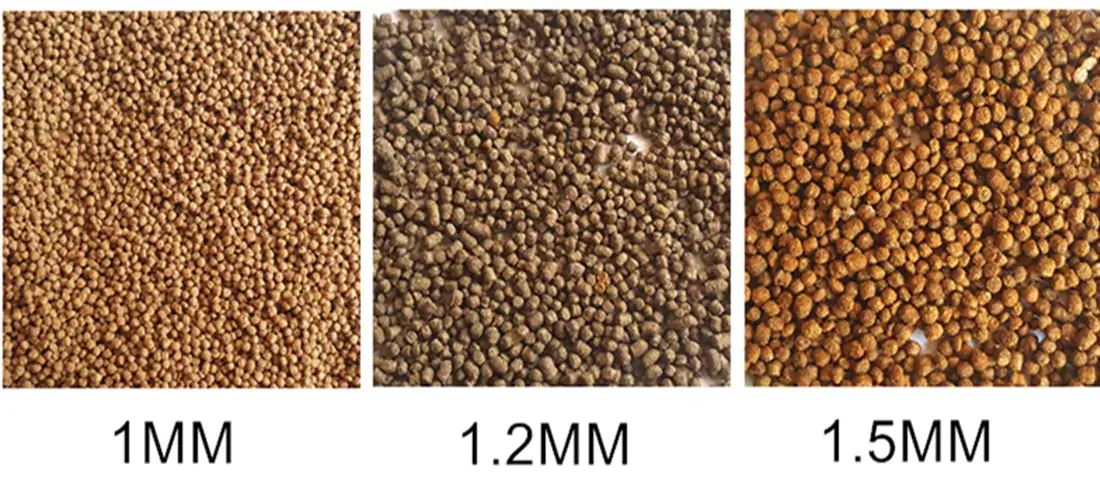

Therefore, the finished granules can float on the water for about 24 hours due to being puffed. Finished sizes range from 0.9mm to 15mm. The dry type machine heats material with an electric plate and extrudes it through die holes via a screw extruder.

When the pellets come out of the machine, the pressure and temperature drop sharply, and the water evaporates. The material is then expanded into particles with a porous structure. During this process, moisture ranges from 15% to 20%.

video of dry type fish feed extruder

working principle of dry type fish feed extruder

During extrusion, material enters through the cavity’s open end, moved by the screw across the cavity. Auxiliary extrusion divides it into zones, each separated by a pressure ring for flow and pressure control. The screw’s action pushes material through gaps, converting screw rotation’s mechanical energy into heat via friction with the machine parts and the material itself.

As the material passes through the die hole at the end of the puffing cavity, it undergoes shaping. The screw’s propulsion in the dry type fish feed machine’s puffing cavity creates immense pressure, shaping the material. As materials exit the die hole, water evaporates instantly, greatly reducing moisture content.

what is wet type fish feed extruder?

The wet type fish feed extruder efficiently transforms raw materials into floating aquatic feed pellets for fish, catfish, shrimp, crab, cats, dogs, and other pets. The raw materials used by the wet type fish feed machine include wheat, soybean cake, and other scraps. Particles from the wet type fish feed extruder float on water for over 24 hours without dissolving.

Large and medium-sized feed processing plants and farms mainly utilize wet type feed extruder machines. Wet type fish feed machines use a steam boiler to supply hot steam for extrusion. They operate similarly to dry type machines but add water or steam to increase moisture to 20% or more, using steam to heat the material.

video of wet type fish feed extruder

working principle of wet type fish feed extruder

the wet type fish feed machine consists of screw, barrel, template, fixture, etc. The screw and barrel sections adjust for feed type and requirements, altering feed expansion. Upon entering the filling device, raw materials need no extra heating; the screw applies high pressure and temperature to cook and sterilize them.

During the high temperature curing process, the starch and fibers in the raw material expand. The material is molded into pellets through the molding die under pressure-sealed conditions. Finally, the front cutter’s high-speed rotation cuts the pressurized product from the screw’s rotation into small puffed balls at room temperature and pressure.

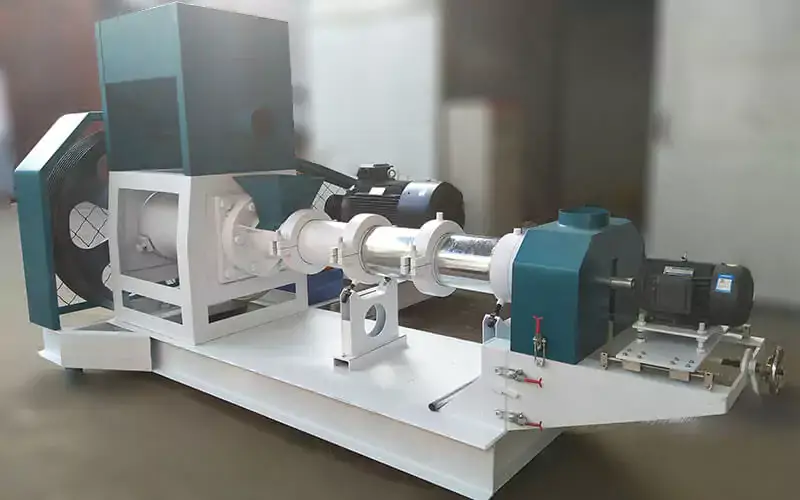

dry type fish feed machine

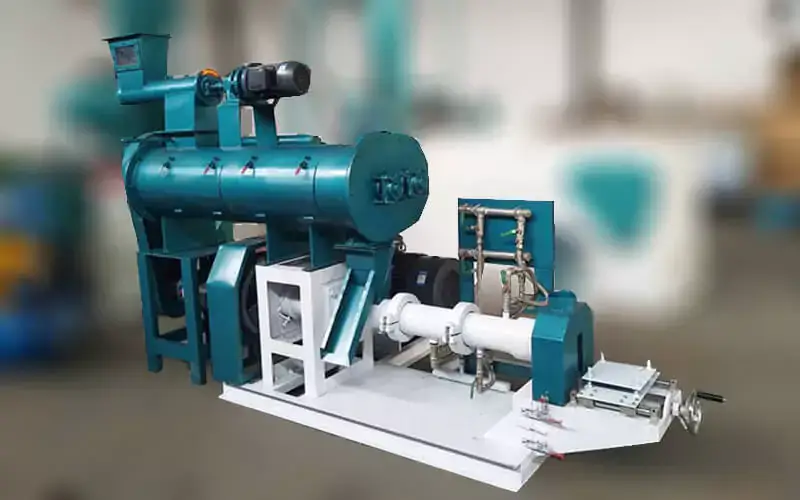

wet type fish feed machine

4 main differences between dry type and wet type

Price

Wet Type: the price for sale is higher

Dry Type: the price for sale is lower

Structure

Wet Type: has conditioner, need steam.

Dry Type: has no conditioner, no need steam.

Effecient

Wet Type: final pellets more smoother and brighter.

Dry Type: smooth, bright, but less than wet type.

Capacity

Wet Type: higher production capacity than dry type with the same power

Dry Type: a bit lower capacity with same power than wet type

sepecifications of wet type fish feed extruder

| Model | Capacity(kg) | Main Power(kw) | Feeding Power(kw) | Cutting Power(kw) | Screw Diameter(mm) | Conditioning power(kw) |

| VTSP-60 | 150-200 | 15 | 0.4 | 0.4 | 60 | 0.37 |

| VTSP-70 | 300-400 | 18.5 | 0.75 | 0.4 | 70 | 1.1 |

| VTSP-80 | 400-500 | 22 | 0.75 | 1.5 | 80 | 1.5 |

| VTSP-90 | 500-600 | 37 | 1.1 | 2.2 | 90 | 2.2 |

| VTSP-120 | 700-800 | 55 | 1.1 | 2.2 | 120 | 2.2 |

| VTSP-135 | 1000-1200 | 75 | 1.5 | 3.0 | 135 | 3.0 |

| VTSP-160 | 1500-2000 | 90 | 2.2 | 3.0 | 160 | 4.0 |

| VTSP-200 | 3000-5000 | 132 | 2.2 | 4.0 | 200 | 5.0 |

specifications of dry type fish feed extruder

| Model | Capacity(kg) | Main Power(kw) | Feeding Power(kw) | Cutting Power(kw) | Screw Diameter(mm) |

| VTGP-40 | 30-50 | 4 | 0.4 | 0.4 | 40 |

| VTGP-50 | 60-80 | 11 | 0.4 | 0.4 | 50 |

| VTGP-60 | 100-150 | 15 | 0.4 | 0.4 | 60 |

| VTGP-70 | 180-250 | 18.5 | 0.4 | 0.4 | 70 |

| VTGP-80 | 300-350 | 22 | 0.4 | 0.6 | 80 |

| VTGP-90 | 400-450 | 37 | 0.4 | 1.5 | 90 |

| VTGP-120 | 500-700 | 55 | 0.4 | 2.2 | 120 |

| VTGP-135 | 700-800 | 75 | 0.4 | 2.2 | 135 |

| VTGP-160 | 1000-1200 | 90 | 1.5 | 2.2 | 160 |

| VTGP-200 | 1800-2000 | 132 | 1.5 | 3 | 200 |