pelleted feed vs extruded feed

Pelleted and extruded feeds are common for horses, chickens, cattle, pigs, fish, and sheep. Choosing between them poses a dilemma. what is the difference between pelleted and extruded feed? which one is better? pelleted feed vs extruded feed?

In the world of animal nutrition, choosing the right feed type is crucial for ensuring optimal growth, health, and productivity. Among the various options available, pellet feed and extruded feed stand out as popular choices. But what sets them apart, and which one is better suited for your livestock? Let’s delve into the differences and benefits of pellet feed versus extruded feed to help you make an informed decision.

extruded feed video

what is extruded feed?

Extrusion is the cooking of the ingredient mixture in an extruder through temperature, humidity and pressure. Moisture lubricates for compression and extrusion, causing starch paste on ingredients at high temperatures for adhesion.

Ingredients puff within 20 seconds, going from air-dried (10-12% moisture) at room temperature to 15-16% moisture at 80-90°C. During the subsequent compression and extrusion of the holes in the die, friction raises the feed temperature to nearly 92°C.

On the other hand, producers create extruded feed through extrusion, subjecting raw ingredients to high temperature and pressure and forcing them through a die to achieve a specific shape. This process gelatinizes starches and denatures proteins, resulting in a highly digestible and palatable feed.

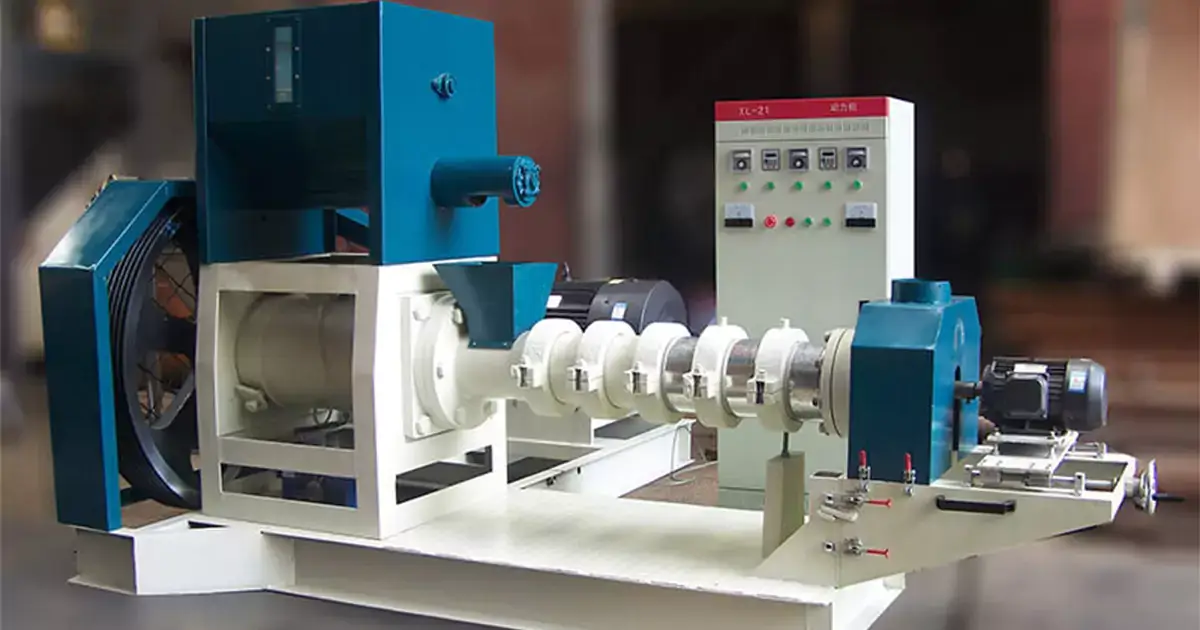

Extrusion compresses and “cooks” food, requiring higher moisture, temperature, and pressure than pelletizing. The extruder feed machine must meet all these requirements upon exit to achieve the desired expansion level. Extruded feed offers lower contamination, longer water stability, nutrient retention, higher digestibility, and efficiency, improving fish farm profitability. Check the fish feed mill equipment list for making extruded feed.

Benefits of Extruded Feed:

- Improved Digestibility: The extrusion process breaks down complex carbohydrates and proteins, increasing the digestibility of nutrients in the feed.

- Enhanced Palatability: Extruded feed often has a smoother texture and more desirable flavor, enticing animals to consume it readily.

- Heat Treatment: Extrusion involves heat treatment, which can help to eliminate harmful bacteria and pathogens in the feed.

- Versatility: Producers can customize extruded feed with various additives, supplements, and medications to meet specific animal nutrition requirements.

- Reduced Anti-Nutritional Factors: The heat and pressure of extrusion can reduce or eliminate anti-nutritional factors present in raw ingredients, further enhancing the feed’s nutritional value.

Machine For Making Extruded Feed

what is pelleted feed?

Pellet feed is a type of animal feed produced by compressing raw ingredients into compact pellets using a pellet mill. The process involves grinding the ingredients, adding binders if necessary, and then compressing them through a die to form uniform pellets. These pellets are then cooled and dried before being ready for consumption.

Manufacturers heat and compress mash into pelleted feed, dense pellets with suitable protein, vitamins, and minerals. Due to their size and digestibility, they’re best for adult hens, not young chicks.

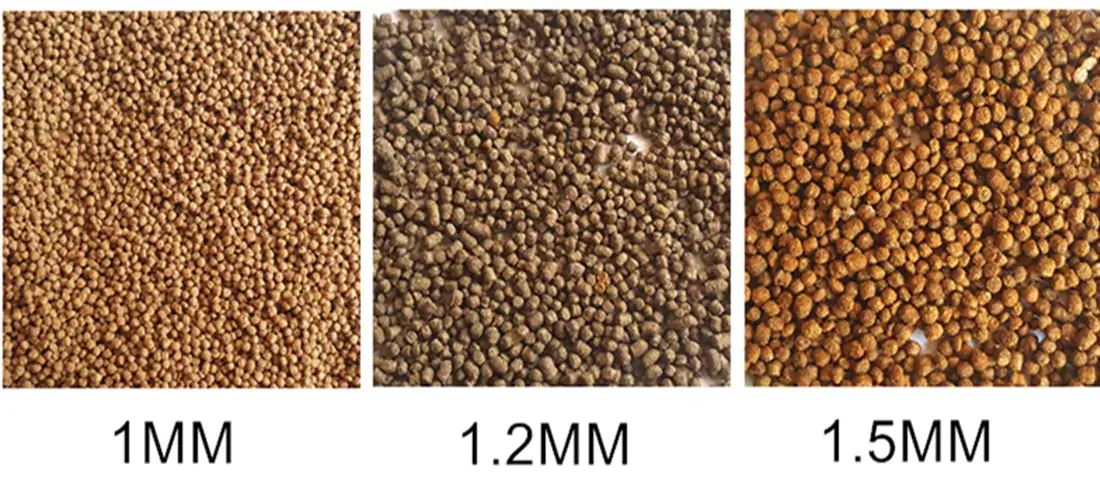

Pelletizing molds small particles into larger, shaped solids using moisture, heat, and pressure, forming dense particles that sink in water. Influential factors are ingredient properties, pre-pelletizing moisture or steam, die thickness, and binders.

Benefits of Pellet Feed:

- Enhanced Digestibility: The compact nature of pellet feed ensures consistent particle size and density, promoting better digestibility in animals.

- Reduced Feed Waste: Pellets are less prone to separation and selective feeding, minimizing feed wastage and improving feed efficiency.

- Nutrient Balance: Pelletization allows for precise control over ingredient composition, ensuring a balanced diet for livestock.

- Convenient Handling: Pellets are easy to store, transport, and dispense, making them ideal for large-scale farming operations.

- Reduced Dust and Fines: Pellet feed produces less dust and fines compared to other feed forms, creating a cleaner feeding environment for animals.

pellet feed video

what is the difference between pelleted and extruded feed?

pellet feed and extruded feed has their own disadvantages and advatages when comparing pelleted feed vs extruded feed.

Extruded Feed: Extruded feeds often have more fat than pelleted feeds to prevent crumbling, offering more calories for hard feeders and high-performance horses. Horses may need days to adjust to extruded feed’s lighter texture. Benefits include less contamination, longer water stability without nutrient loss, higher digestibility, and improved efficiency and conversion rates.

Pelleted Feed: One of the main advantages of pelleted feed compared to extruded feed is the lower manufacturing cost; however, it has many disadvantages than extruded feed.

Machine For Making Pelleted Feed

Both pellet feed and extruded feed offer distinct advantages in terms of digestibility, palatability, and convenience. The choice between the two depends on factors such as animal species, nutritional requirements, and production preferences. Whether you opt for pellet feed or extruded feed, prioritizing quality ingredients and proper formulation is essential for ensuring the health and performance of your livestock.