Introduction of Pellet Processing Plant

Pellets can be used in many ways. They work well. They let us change raw materials. These materials are often in large amounts. Pellets turn them into useful forms. These forms are easy to handle. Pellet processing plants are big factories. They make this change happen on a large scale. These plants are important in many areas.

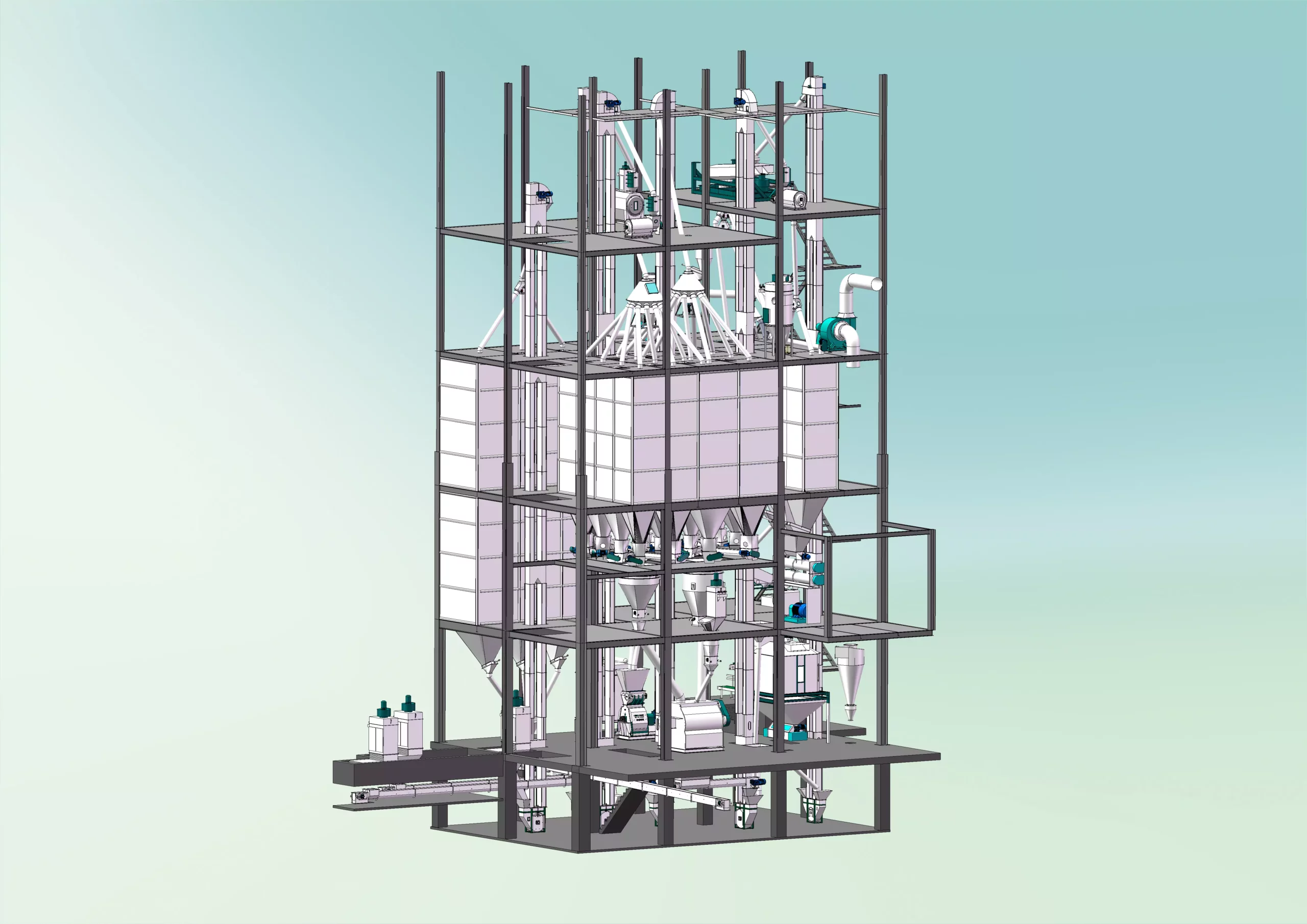

What is a Pellet Processing Plant?

A pellet processing plant is a type of factory. It has many machines. These machines are linked. They work together. These plants take raw bulk materials. These can be wood, farm leftovers, or feed parts. The machines turn these into small, heavy, same-size pellets.

The main aim of a pellet plant is to make the first material better. When it is turned into pellets, it is easier to move and store. It gets heavier and takes up less space. Making pellets can also make the material work better. Or it can make it more valuable when used as fuel or animal feed.

Why Invest? Common Uses & Good Things About Pellets

Making pellets has many good points. That is why pellet processing plants are used for many things.

More Material in Less Space

Pellets are much heavier than the raw stuff they come from. For example, wood pellets are heavier than sawdust. This means pellets take up less room. This makes storing and shipping them easier. It also costs less.

Easier to Handle and Less Dust

Pellets are all the same size and shape. This makes them easy to manage with machine systems like belts. They flow smoothly. Also, the material is packed tight into pellets. So, there is much less dust than when handling raw, loose stuff. This makes the workplace safer and cleaner.

Better Energy (for Fuel Pellets) or Food Value (for Feed Pellets)

When raw stuff is turned into pellets, its features can get better. For example, fuel pellets often burn better. They burn more evenly than raw biomass. Animal feed pellets can give balanced food better. This is because all food parts are mixed in each pellet.

Using Waste and Leftovers

Pellet plants are a great way to turn low-value waste into good products. For example, sawdust from wood mills can become fuel pellets. Straw from farms can also become fuel pellets. This helps use things better. It can also make new money.

Types of Pellet Processing Plants (Based on What They Make)

The name “pellet processing plant” is wide. Many different materials can be made into pellets. Here are some common types of plants. They are grouped by what they make:

- Wood Pellet Plants: These plants make fuel pellets. They use things like sawdust, wood chips, and other wood leftovers. People use these wood pellets to heat homes and businesses. They also use them to make power.

- Animal Feed Pellet Plants: These animal feed pellet plants make healthy, balanced feed pellets. They make feed for many kinds of animals. This includes food for chickens, cows, pigs, fish, and shrimp.

- Biomass Pellet Plants: These plants make fuel pellets from other plant stuff. Common things used are farm leftovers like straw, rice husks, and corn cobs. Parts of palm oil trees can also be used. Special energy crops can be made into pellets too.

- Fish Feed Pellet Plants: These fish feed pellet plants make floating or sinking fish feed for different aquatic. Making fish food into pellets makes it easier to handle. It is also easier to spread evenly on fields. Pellets can also release food for plants slowly.

- (Other Types): Pellet production is also used for other things. For example, it is used to recycle plastics. Some chemicals are also made into pellets to make them easier to handle.

Cost Breakdown: From Garage Startup to Industrial Plant

Here’s what you’ll actually pay (2024 data from 37 real projects):

| Expense | Home Business | Mid-Size Plant | Factory Scale |

|---|---|---|---|

| Pellet Machine | USD18,000 | USD85,000 | USD450,000+ |

| Safety Systems | USD2,500 | USD18,000 | USD75,000 |

| Monthly Profit* | USD4,200 | USD23,000 | USD120,000 |

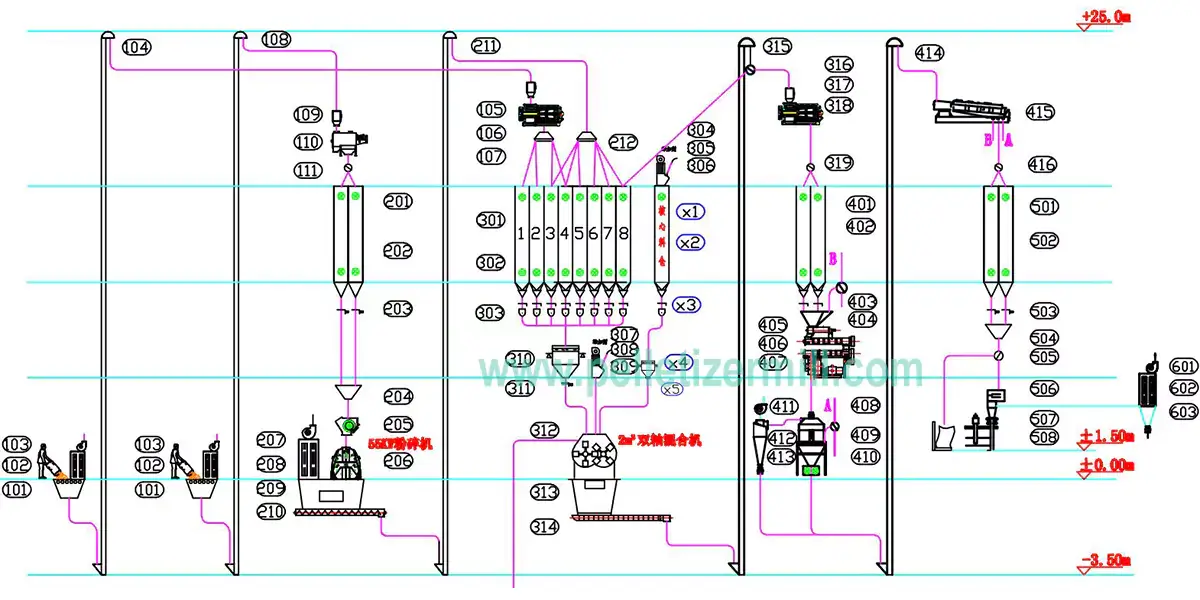

Main Machines in a Typical Pellet Processing Plant

Feed processing equipment can change based on the raw stuff and pellet type. But most pellet plants have some main parts:

Machines to Get Raw Stuff Ready:

Before making pellets, raw stuff often needs work. This can be Chippers (for big wood). It can be Crushers (for bulky plant stuff). It can be Screens (to take out dirt or metal). Industrial Dryers are used to lower wetness if the raw stuff is too damp.

Grinding Area (Hammer Mills):

This area grinds the ready raw stuff. It makes it into a fine, even powder. The right powder size is key for good pellets.

Mixing Area (Mixers):

If many different raw things are used, a mixer blends them well. Binders or other extra things are also added here. This makes sure the stuff going to the pellet mill is the same all through.

Conditioning Area (Steam Conditioner):

This step is very common. It is used a lot for animal feed and many plant pellets. A conditioner adds steam and/or water to the ground stuff. This softens the stuff. It can help natural binders in wood work better. It usually makes the final pellets better and stronger.

Pelleting Area (Pellet Mill – Ring Die or Flat Die types):

This is the main part of the pellet processing plant. The pellet mill uses rollers and a die. A die is a metal plate with holes. The mill presses the conditioned stuff hard. It pushes it through the holes. This forms heavy pellets.

Cooling Area (Cooler):

Pellets come out of the mill hot. They are often 70-90°C. They are also a bit soft. A cooler uses air to lower their heat. This helps harden the pellets. It also takes out some extra water.

Screening Area (Sifter):

After cooling, the pellets go through a sifter. This takes out any fine dust. It also takes out any pellets that are too big or broken. This makes sure only good, same-size pellets go to bagging.

Packing Area (Baggers):

The last step is to weigh the finished pellets. Then they are put into bags. This can be done by hand, or by machines that are partly or fully automatic.

3 Innovative Pellet Products (Maximize Profits)

The most successful plants diversify with:

| Product | Startup Cost | Profit Margin |

|---|---|---|

| Pet Food Pellets | USD8,000 | 42% |

| Coffee Ground Fuel | USD12,500 | 58% |

| Medicinal Herbs | USD25,000 | 67% |

The General Pellet Making Process: A Step-by-Step Look

Details can change. But the basic steps in most pellet processing plants are these:

- Get Raw Stuff, Prepare & Store It: Raw stuff arrives. It is often cleaned. It might be dried or chopped. Then it is stored.

- Grind It: The stuff is ground. It is made into the fine powder needed for pellets.

- Mix It: If needed, different things or extras are blended together.

- Condition It: Water and heat are changed, usually with steam.

- Make Pellets: The conditioned stuff is pushed through the pellet mill. This forms the pellets.

- Cool It: The hot pellets are cooled. This makes them stable.

- Screen It: Dust and wrong-size pellets are taken out.

- Bag & Store Finished Pellets: The final product is packed.

Think About for Starting or Buying Pellet Processing Plant

Setting up a pellet processing plant is a big job. Good planning is key.

Raw Stuff: Is It Available? What Quality? What Cost?

This is the most important thing. You need a sure, steady, long-term supply of good raw stuff. It must also be at a good price.

Market for Your Pellets:

Who will buy your pellets? Is there enough need for them nearby or for export? What are the current market prices? What quality do buyers want?

Plant Size, Design & Machines:

You need to match the plant’s size. The machines you pick (like the type of pellet mill or dryer) must fit your raw stuff. They must also fit your target market and your budget.

Site Choice & Needs:

Think hard about the location. How close is it to your raw stuff? How close to your buyers? You also need enough space. And you need things like power and water.

Green Rules & Permits:

You must know and follow all local green rules. You will likely need permits to run the plant. Think about where your raw stuff comes from too. Is it sustainable?

Money Plan, Costs & Savings:

Pellet plants cost a lot of money. You will need a full business plan. This plan should list all costs. It should guess your possible return on what you spend.

Workers & Skills:

Running a plant well needs skilled people. They need to operate and fix the machines. Plan for training and hiring good staff.

FAQ About Pellet Processing Plant

1. What are the main raw materials used in pellet plants?

This changes a lot. It depends on the type of pellet being made. Common raw stuff includes wood (like sawdust and chips). It includes farm leftovers (like straw, rice husks, and corn parts). It includes animal feed parts (corn, soybean meal, wheat) and things for making fertilizers.

2. Is owning a pellet plant profitable?

If a pellet plant makes money depends on many things. How much does your raw stuff cost? Can you always get it? What is the selling price for your pellets? How well does your plant run? What are your running costs (power, workers)? How big is your plant? You need a full business plan to guess how much money you can make.

3. What’s the main difference between a flat die and a ring die pellet mill?

Usually, flat die pellet mills have a simpler design. They are often used for smaller plants. Or they are used for making pellets from softer stuff. Ring die pellet mills are more common in bigger, factory-type plants. They can usually make more pellets. They can also handle harder stuff better. And they often make pellets that are more even and strong.

Conclusion

Pellet processing plants can do many things. They can change a wide range of raw stuff into useful products. These products are dense. They are easy to handle. They work well. These plants play big roles in making energy. They are also key in farming and using waste well.

To do well in this business, you need good research. You need careful planning. It costs a lot of money. And you need to run the plant well. But for those who do it right, the rewards can be largest.