| Price | 30000-100000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

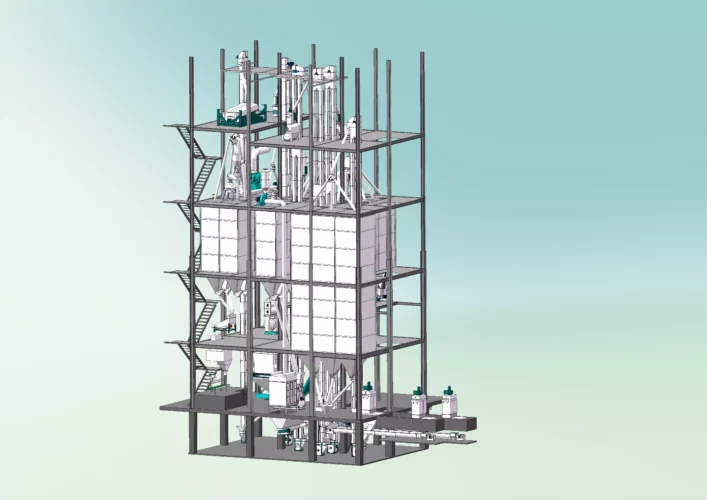

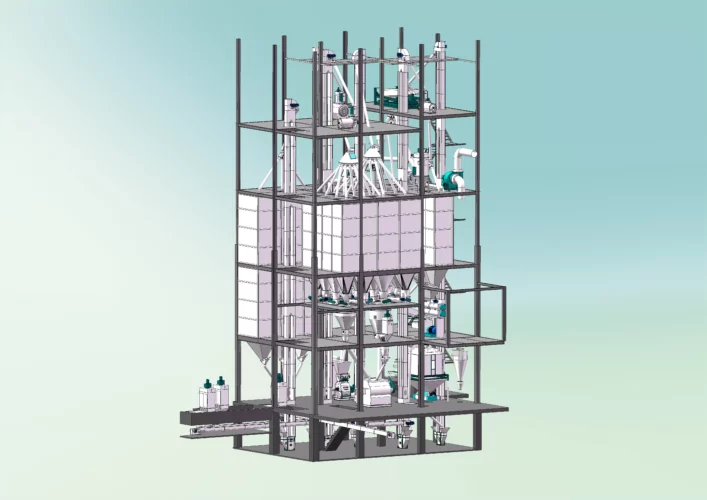

Animal Feed Pellet Plant Overview

| Production Output | 3-5 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal/cake, edible leaf, fish meal, bone powder, grass meal, hay meal, etc |

| Type | flat die type and ring die type |

| Final Pellet Size | 2-10 mm |

| Application | producing animal feed and poultry feed pellets |

| Used For | cattle feed production, goat/sheep feed production, rabbit feed production, deer feed production |

Introduction

If you are in the livestock or poultry business, you know one thing is true. High-quality feed is the engine for your whole farm. But buying feed from suppliers can be costly. The quality can also change. Owning your own animal feed plant offers a good solution. It gives you control over quality, costs, and your own supply.

This guide is a practical roadmap for business owners and large-scale farmers. We will cover what a feed plant is and the machines you will need. We will also look at the production process. Finally, we will go over the key steps for planning your investment.

What Exactly is an Animal Feed Plant?

An animal feed plant is a special type of factory. It has a complete system of machines that work together. This system takes raw ingredients and processes them into finished feed. The feed is nutritionally balanced for different types of animals.

A “plant” is different from a single machine on a small farm. A plant is designed for medium to large-scale production. It focuses on making large amounts of feed well and with the same quality every time.

The Core Advantages of Owning Your Own Feed Plant

Having your own feed plant offers several powerful business advantages.

Drastic Cost Reduction Through Bulk Purchasing

You can buy your raw ingredients, like grains and protein meals, in large amounts. Buying this way at wholesale prices avoids the extra costs of commercial feed. This can lead to very large savings over time.

Total Control Over Feed Quality and Formulation

This is a key benefit. You can create precise recipes for different animals. You can also make different feeds for different life stages. This ensures your animals get the exact nutrition they need for the best results.

Consistency is Key to Animal Performance

Producing the same high-quality feed every day leads to healthier animals. It also leads to more stable growth rates. This gives you more predictable results, like milk yield or egg numbers.

Flexibility to Serve Different Markets

A versatile plant can produce feed for different animals. You could make poultry feed one day and cattle feed the next. You do this by changing the recipe and some machine settings.

Potential for a Profitable Business

Besides making feed for your own animals, a plant gives you a chance to sell feed. You can sell to other local farmers. This can create a new and profitable business for you.

What Kinds of Feed Can a Plant Produce?

A well-equipped animal feed plant can be set up to make many different types of feed.

- Poultry Feed: This includes feed for broilers and layers. This type of feed often needs to be made into pellets. Then it is broken into “crumbles” for young chicks.

- Livestock Feed: This includes feed for cattle, pigs, sheep, and goats. This feed is often made into a larger pellet or cube shape.

- Specialty Feeds: This could be feed for other animals like rabbits or horses.

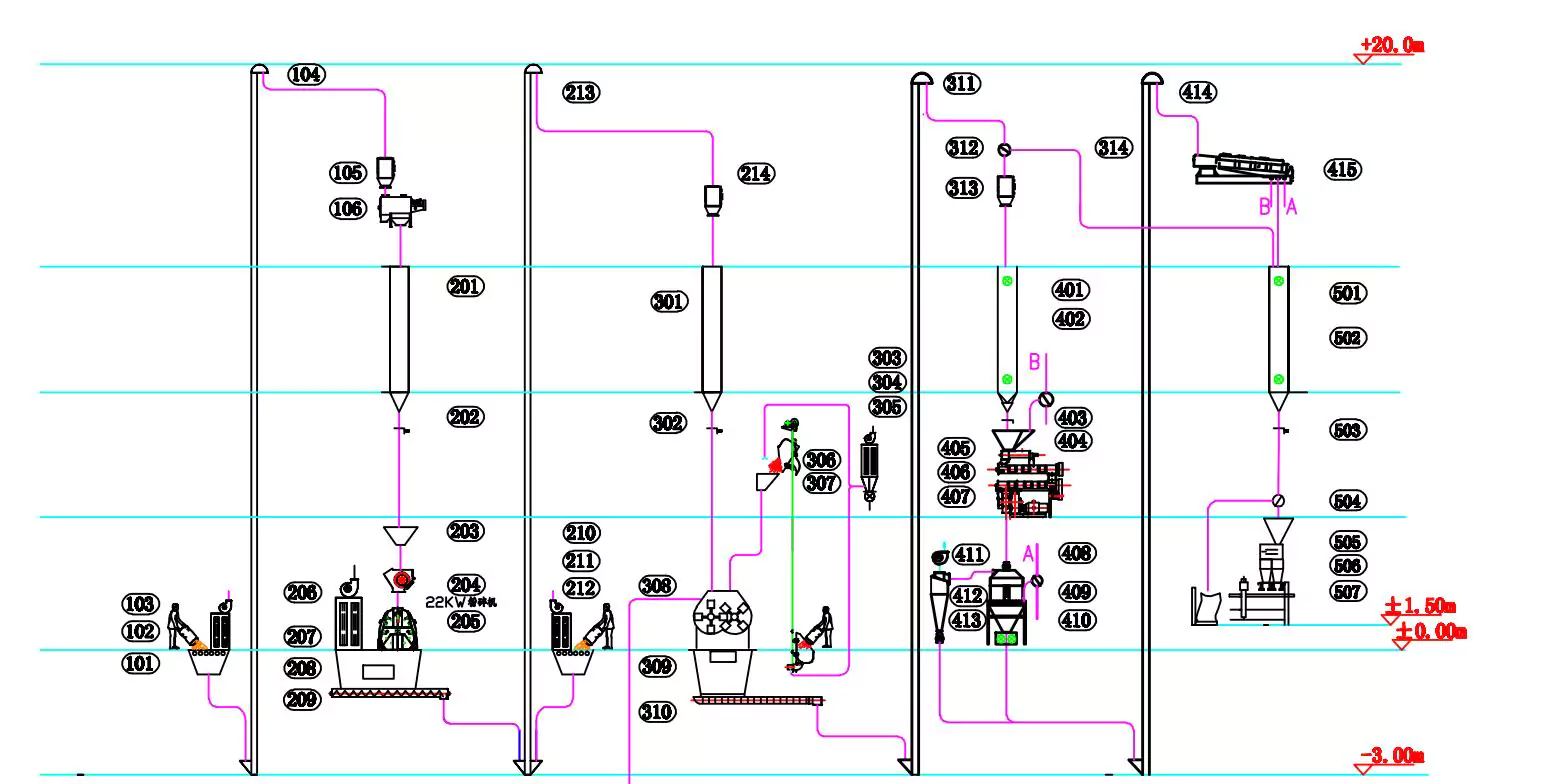

Inside the Plant: Key Machinery for Animal Feed Production

A modern animal feed plant has several key machines that work together as a system.

Raw Material Receiving & Storage Systems:

This is where you receive, check, and store your raw ingredients.

The Grinding Section (Hammer Mill):

This machine grinds the ingredients into a uniform, fine powder. This is important for good mixing and for animals to digest the food easily.

The Mixing Section (High-Efficiency Mixer):

This machine thoroughly blends all the ground ingredients. It also mixes in important micro-ingredients like vitamins and minerals.

The Conditioning Section (Steam Conditioner):

In this machine, steam is added to the mixed feed. This helps to cook the starches. It also kills some bacteria and prepares the mix for pelleting.

The Pelleting/Shaping Section (The Core Choice):The Pellet Mill:

This is the workhorse for making most standard sinking pellets for livestock and poultry.

The Drying & Cooling Section:

These machines remove extra moisture from the pellets. They also bring them down to a safe temperature for storage.

The Screening & Sifting Section:

This machine removes any fine dust or broken pellets. This ensures a uniform final product.

The Bagging Section:

This section has machines that weigh the feed and pack it into bags.

The Animal Feed Production Process: A Step-by-Step Overview

Here is a general look at how feed is made in a plant:

Sourcing, Receiving, and Testing Raw Ingredients: Good ingredients are brought in and checked for quality.

Grinding: The ingredients are ground to the correct particle size.

Batching & Precise Mixing: The correct amount of each ingredient is weighed. Then it is blended perfectly according to the feed formula.

Conditioning with Steam: The mixed mash is conditioned with steam to get it ready for shaping.

Pelleting or Extruding: The mash is formed into pellets.

Drying and Cooling: The finished pellets are dried and cooled to make them stable.

Sifting for Uniformity: Any dust or wrong-sized pellets are removed.

Bagging and Storing the Finished Product: The final feed is packaged for use or for sale.

Planning Your Animal Feed Plant: A Strategic Checklist.

Starting a feed plant is a major project. Careful planning is the key to success.

Step 1: Market Research & Business Plan

Who are your customers, even if it’s just your own farm? What type of feed do they need? What is your budget and your expected return on your investment?

Step 2: Determine Your Production Scope & Capacity

What animals will you primarily make feed for? How many tons per hour do you need to produce to meet your demand?

Step 3: Secure Your Raw Material Supply Chain

“This is a make-or-break factor for any feed plant. Can you get a consistent supply of high-quality, affordable ingredients all year round? Your whole operation depends on this.”

Step 4: Site Selection and Facility Design

You need to think about logistics for getting raw materials in and shipping finished feed out. You will also need proper utilities like power and water.

Step 5: Select the Right Technology & Machinery Supplier

Look for suppliers with a strong reputation. They should have experience with the type of feed plant you want to build. Good after-sales support and training are also very important.

Step 6: Understand Local & National Feed Regulations

Research the rules for making feed in your area. This is especially important for safety. It is also key for labeling if you plan to sell the feed.

FAQ

1. What is the main difference between a feed plant for poultry and one for cattle?

The main process of grinding, mixing, and pelleting is similar. However, the machines might be different. For example, cattle feed may require stronger grinders for roughage and larger pellet dies. Poultry plants will almost always need good sifters and often a “crumbler” machine to break pellets into smaller pieces for young chicks.

2. Do I need an extruder or a pellet mill for my animal feed plant?

This depends on the kind of feed you want to make. For most standard livestock and poultry feed, a pellet mill is the right and most common choice. If you specifically want to make floating fish feed or certain types of specialty pet foods, then you will need the more specialized and more expensive extruder.

3. How much does it cost to start a small animal feed plant?

This is a very large investment. Even a small-scale but complete plant (for example, one that makes 1 ton of feed per hour) can cost from tens of thousands to over a hundred thousand US dollars. The final price depends a lot on the level of automation, the quality of the machinery, and the scope of the plant.

4. What is the most important factor for making high-quality animal feed?

While good machines are important, most experts agree on two things. The most critical factors are the quality of your raw ingredients and the accuracy of your feed formulation (your recipe). A great plant cannot make good feed from bad ingredients or from a poor recipe.

5. Can I use the same plant to make feed for different animals?

Yes, this is a key advantage of having a versatile plant. You can produce feed for chickens, cattle, goats, pigs, and more in the same plant. You do this by changing the feed formulation (the recipe) and changing the die in the pellet mill to make a different sized pellet.