| Production Output | Range from 0.1 to 5 t/h |

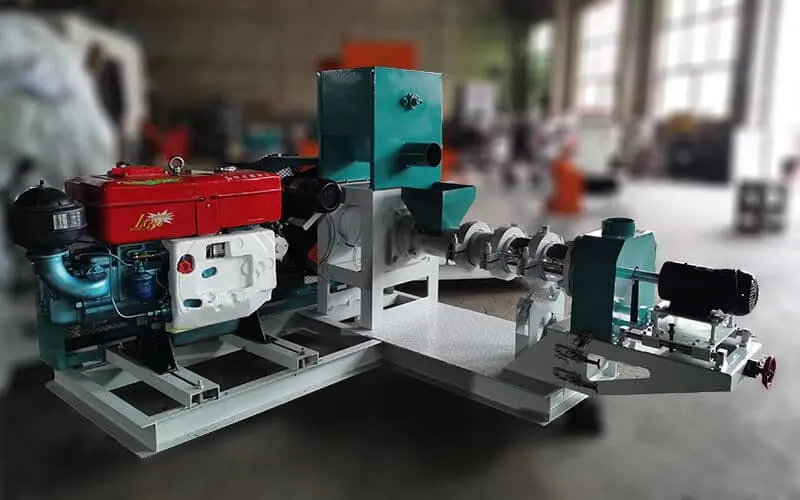

| Power Type | Electric motor or diesel engine |

| Raw Materials | Cereal, corn, wheat, barley soybean, oil seed, fish meal, bone meal, meat meal, etc. |

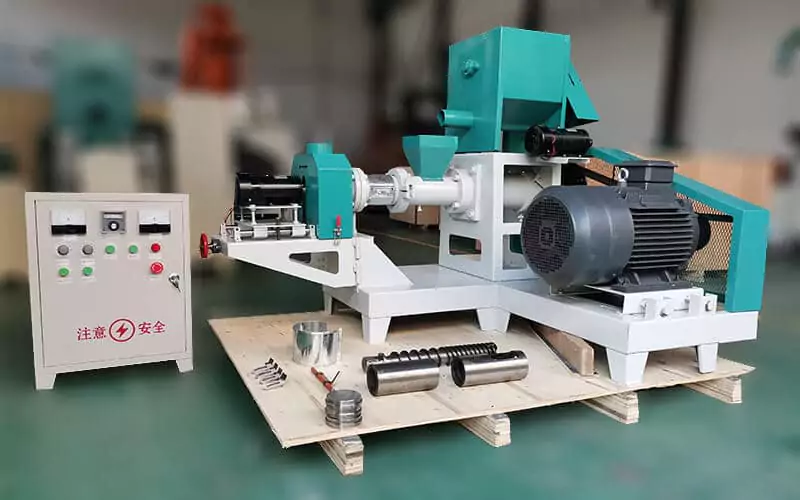

| Type | dry type floating fish feed pelletizer |

| Final pellet size | 0.9mm, 1mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, etc. |

| Used For | floating pellets for catfish, tilapia, carp, trout, etc. |

what is floating fish feed pellet mill

Floating fish feed pellet mill is a specialized machine for processing aquatic feed. It works by extruding raw materials like corn, soybean meal, fishmeal, and other minerals. This equipment produces aquaculture feed pellets that have stable buoyancy and settling properties.

Because of the improved extrusion technology, fish feed processing efficiency can increase by 85% to 95%, and fish digestibility can improve by around 10% to 15%. This reduction in feed waste is significant.

The floating fish feed pellet machine can adjust the final pellet size and hardness. It can also customize the nutritional content based on different growth stages, such as fry and adult fish. This customization helps ensure efficient fish growth and cost-effective feed use during aquaculture.

The fish feed pelletizing equipment has become essential in modern fish feed processing. It boosts production capacity, ensures stable feed quality, and optimizes cost structure.

how does the foating fish feed pellet machine work

The core working principle of floating fish feed pellet making machine is the advanced extrusion technology. This technology uses high temperatures, high pressures, and high shear forces to puff and shape pelleted feed. The whole process is divided into the following main steps:

- Preparation and mixing of raw materials: After accurately weighing raw materials such as soybean meal, fish meal, corn meal, vitamins, and minerals based on the formulation, you need to mix them using a high-speed mixer to equalize the distribution of nutritional components.

- Feeding and conveying: The mixture is steadily fed into the extrusion chamber of the floating fish feed pellet mill through the feeder to maintain continuous and equal amount of feeding.

- Extrusion and shaping reactions: A screw propels the material at high speed, subjecting it to intense shear and frictional heating. According to industry data, the maturity level reaches 85%-95%.

- High temperature and high pressure treatment: The extrusion chamber temperature is usually over 100℃, which promotes complete gelatinization of starch, denaturation of proteins, and effectively inactivates pathogenic bacteria such as Salmonella.

- Expansion and forming: The material undergoes instantaneous decompression within the mold cavity, causing its internal moisture to evaporate and expand, forming a sponge-like structure.

- Granular cutting: The continuously extruded material is cut to a set length using a cutter to make the pellet size uniform.

- Drying/cooling: After reducing the moisture content to approximately 10-12% in a dryer, the structure is stabilized by cooling, and the product is finally transferred to the packaging process.

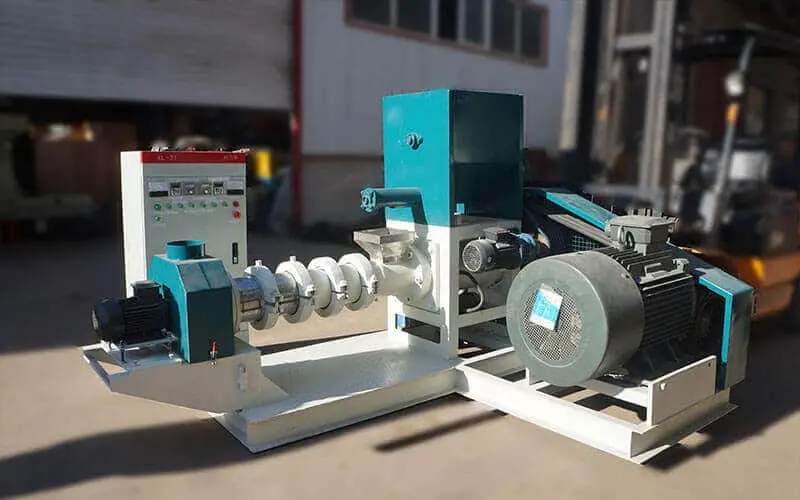

Floating fish feed pellet mills: dry process vs. wet process

When choosing a floating fish feed pellet making machine, you need to know the main difference between dry fish feed machine and wet fish feed machine. It is a core factor that affects production capacity, feed quality and investment cost.

According to industry statistics, the maturity of wet extrusion process usually reaches 90%-98%, while dry process generally stays at 85%-93%, making wet process more advantageous in commercial aquafeed production lines.

The table below shows the main differences in working principle, production capacity and application scenario of both fish feed processing equipments. It can help you compare and select the best floating fish feed equipment in quick. You can get more details from dry vs wet fish feed machine.

The main difference between dry-type extruders and wet-type extruders

| Item | Dry Type Extruder | Wet Type Extruder |

|---|---|---|

| working principle | Heating by electric plate | heating by steam boiler |

| production Capacity | medium production good for medium and small farm | high yield good for large farm and commerical feed factory |

| fish feed quality | Good ripening | 90%-98% ripeness with high stability |

| cost structure | Low cost, no boiler required | high cost, need steam boiler |

| good for | Small and medium-sized farmers and individual processors | Commercial feed mills and large-scale farms |

| feed type | floating type | floating type |

The Advantages of Floating Fish Feed Pellet Mill

Why should farmers use pelleted feed? Pelleted feed offers numerous significant advantages to aquaculture efficiency. It has become a standard method in modern fish farming systems. The main advantages are as follows:

- Improved feed conversion ratio: During the fish feed extrusion process, starch gelatinization can reach 85% to 95%, thereby the energy and protein intake for fish is increased by 10% to 15% and boosting significantly their growth.

- Reduced feed costs: You can use local raw materials (such as rice bran and wheat bran), to produce feed using floating fish feed pellet mill. At this way you can reduce total feed costs by 20% to 40% compared to commercial fish feed.

- Reduced water pollution: The finished feed pellets can remain undissolved in water for about 12-24 hours with highly stability. And preventing the accumulation of ammonia nitrogen and nitrite in uneaten feed, thereby improving the environmental impact of aquaculture ponds.

- Elimination of harmful bacteria: The high-temperature, high-pressure treatment during the extrusion stage can inactivate pathogens such as Salmonella, thereby improving the health status of fish fry and reducing medication costs.

- Personalized nutritional formulation: Protein content and pellet size can be flexibly adjusted according to the needs of fry, fingerlings, and adult fish.

spare Parts: Screw and Die for fish feed pellet mill

High-quality wear parts are crucial for continuous operation. We supply durable screw rods, die molds, and cutting blades made of alloy steel to minimize downtime.

How to Choose the Right Fish Feed Pelletizer for Your Fish Farm

Selecting the right floating fish feed pellet mill for a fish farm requires a systematic evaluation across four core dimensions: output, feed type, power source, and budget. This ensures the equipment is highly compatible with actual production needs.

Define Your Production Capacity

Small-scale fish farmers: typically require 40–100 kg/hour and often use simple, low-energy and small dry-process electric fish feed pellet mill to meet daily feeding needs.

Medium-sized farms: require a higher production capacity of 150–500 kg/hour and are better suited to medium-sized dry-process equipment or small wet extruders to improve pellet consistency and production stability. Commercial feed mills typically require large-scale continuous production of 1–10 tons/hour, thus necessitating wet extrusion production lines to ensure pellet consistency and long-term operational efficiency.

Determine the type of feed you need (floating feed vs. sinking feed)

Floating feed: is suitable for mid-to-upper-level fish such as tilapia and grass carp, and can be stably produced using both dry and wet processing equipment.

Sinking feed: for bottom-dwelling species such as shrimp, prawns, and trout, high-density is required. Wet floating fish feed machine, due to their more precise conditioning and cooking capabilities, can better control particle density, producing sinking feed with higher stability in the water.

Consider Your Power Source

Electric motor: is the most common form of power, suitable for areas with stable industrial power supply and lower operating costs.

Diesel engine: is more advantage for remote areas or areas lacking three-phase power, ensuring continuous production of the fish feed pellet making mill even without a stable power supply.

electric Type

diesel engine type

Assess Your Budget and Supporting Equipment

When developing your equipment budget, you should include all upstream and downstream processes such as crushers, mixers, dryers, coolers, and packaging machines in your investment plan to build a complete feed processing system. If you choose a wet fish feed machine, you must also configure a steam boiler to ensure the stable achievement of raw material conditioning and high degree of maturation.

Electric and Diesel Floating Feed Machine specifications

electric fish feed machine

| Model | Capacity(kg) | Main Power(kw) | Feeding Power(kw) | Cutting Power(kw) | Screw Diameter(mm) |

| VTGP-40 | 30-50 | 4 | 0.4 | 0.4 | 40 |

| VTGP-50 | 60-80 | 11 | 0.4 | 0.4 | 50 |

| VTGP-60 | 100-150 | 15 | 0.4 | 0.4 | 60 |

| VTGP-70 | 180-250 | 18.5 | 0.4 | 0.4 | 70 |

| VTGP-80 | 300-400 | 22 | 0.4 | 0.6 | 80 |

| VTGP-90 | 400-500 | 37 | 0.4 | 1.5 | 90 |

| VTGP-120 | 500-700 | 55 | 0.4 | 2.2 | 120 |

| VTGP-135 | 800-1000 | 75 | 0.4 | 2.2 | 135 |

| VTGP-160 | 1000-2000 | 90 | 1.5 | 2.2 | 160 |

| VTGP-200 | 2000-3000 | 132 | 1.5 | 3 | 200 |

diesel engine fish feed machine

| Model | Capacity(kg) | Main Power(HP) | Feeding Power(kw) | Cutting Power(kw) | Screw Diameter(mm) |

| VTGP-40 | 30-50 | 12 | 0.4 | 0.4 | 40 |

| VTGP-50 | 60-80 | 17 | 0.4 | 0.4 | 50 |

| VTGP-60 | 100-150 | 22 | 0.4 | 0.4 | 60 |

| VTGP-70 | 180-250 | 28 | 0.4 | 0.4 | 70 |

| VTGP-80 | 300-400 | 32-35 | 0.4 | 0.4 | 80 |

| VTGP-90 | 400-500 | 50 | 0.4 | 1.5 | 90 |

| VTGP-120 | 500-700 | 75 | 0.4 | 2.2 | 120 |

FAQ

A: Yes. Changing the die plate allows farmers to produce pellets of different sizes for juvenile or adult fish.

A: Both are durable with maintenance. Wet extruders generally have lower wear rates due to smoother processing.

A: Floating feed floats on water; sinking feed sinks. Wet fish feed making machine can better control pellet density for stability.

A: In short: Yes. In most fish farms, making your own feed using a floating fish feed making machine can save 30% to 50% in costs compared to buying commercial fish feed, especially in areas where raw materials are locally sourced and energy costs are low.

Q: What is the price range for fish feed pellet mills?

| Type | Capacity | Price Range (USD) | Application |

| small scale dry fish feed machine | 40 – 100 kg | $800 – $2,500 | small fish farm and individual |

| medium dry fish feed mill | 200 – 500 kg | $3000 – $5,000 | Medium-sized farms and small cooperatives |

| commerical fish feed mill | 1 – 5 tons | $20000 – $200,000+ | commercial fish feed factory and large fish farm |