Introduction of Fish Farming in India

For fish farmers across India, from the ponds of Andhra Pradesh to the fisheries of West Bengal, the cost of quality fish feed can determine the success of your entire operation. Relying on commercial feeds can be expensive and their prices can change unexpectedly. An on-farm fish feed making machine is a powerful way for Indian farmers to control these costs. It also allows you to use local agricultural by-products and create specialized, high-quality feed for your fish.

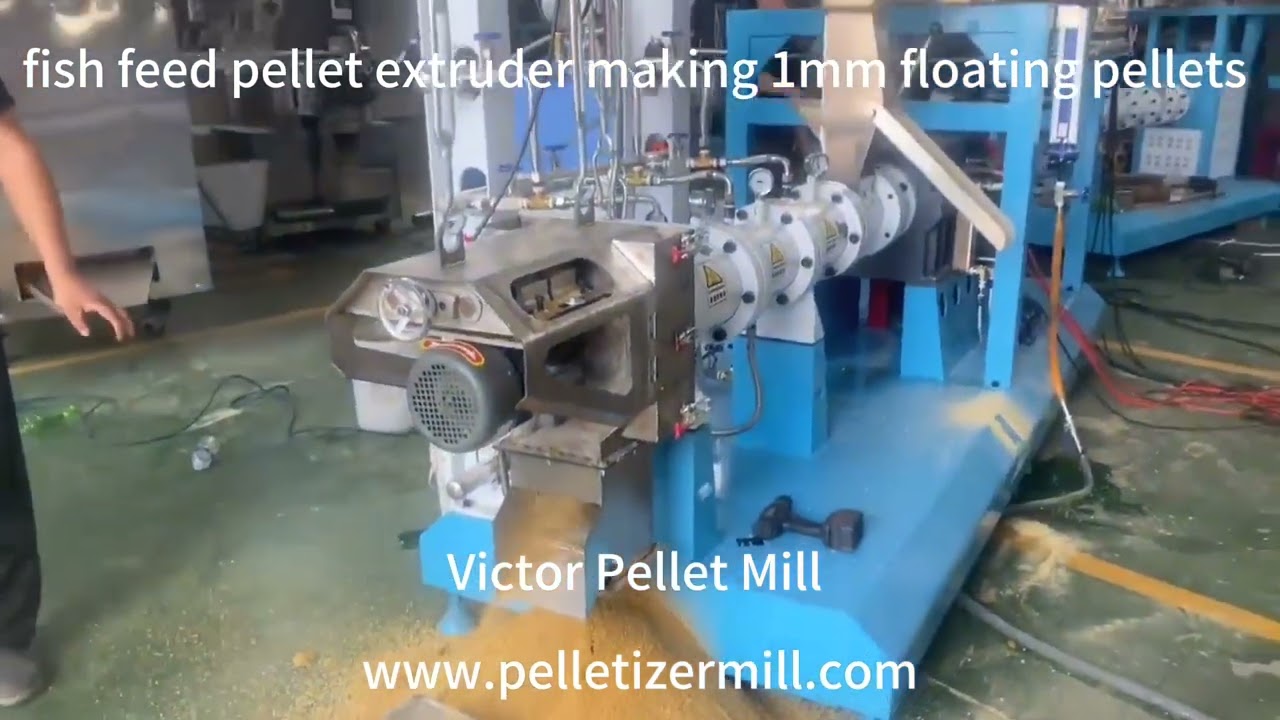

video of floating fish feed extruder machine in India

Why a Fish Feed Machine is a Smart Investment for Your Indian Farm

Investing in your own feed making machine offers clear advantages for your farm in India.

Take Control of High and Fluctuating Feed Costs

Making your own feed reduces your reliance on commercial feeds. The prices of these feeds can change with market conditions. On-farm production gives you more stable and predictable costs.

Use Local Indian Ingredients to Your Advantage

You can create high-quality feed using locally available and often cheaper ingredients. These include common Indian agricultural by-products like rice bran, mustard oil cake (sarso ki khal), groundnut cake, maize (corn), and local fish meal from coastal states.

Create Custom Feed for Your Specific Fish

This is a major benefit. You can tailor your feed nutrition for popular Indian aquaculture species. This includes Indian Major Carps (like Rohu and Catla), Tilapia, and Catfish (Magur).

Ensure a Consistent Supply of Fresh, Quality Feed

Having your own machine means you can make fresh feed whenever you need it. Fresh feed is often more nutritious and more appealing to fish. This can lead to better health and faster growth.

Exploring the Different Fish Feed Making Machine in India

There are several manufacturers of floating fish feed machine in India that offer floating fish feed making machines tailored for different needs. From floating fish feed machines to ones specifically designed for certain species, the options are vast. Researching and comparing different brands, checking their reviews, and understanding the equipment’s production capabilities can lead you to make an informed decision.

Floating Fish Feed Machines

These are designed to produce buoyant feed pellets that float on the water’s surface, ideal for top and mid-water feeders.

Wet Type:

Uses a method of extrusion that requires a steam boiler. The feed produced is more water-stable, making it suitable for certain species that take longer to consume their feed. However, this method is typically more expensive due to the machinery involved and the energy it consumes.

Dry Type:

Doesn’t require a steam boiler, making it more cost-effective and easier to operate. The dry type process is typically faster but might result in slightly less water stability in the produced feed.

Sinking Fish Feed Machines

These sinking fish feed machines produce feed that settles to the bottom, ideal for bottom-feeding species.

Small Scale:

Perfect for smaller farms or specialized farming. They are more affordable and easier to handle, but might not be suitable for commercial-scale production.

Large Capacity:

Built for large-scale aquaculture operations, these floating fish feed making machine in India can produce a significant quantity of feed in a short time. Their robust nature means they are durable but also more expensive initially.

The Key Choice: Extruder vs. Pellet Mill for Your Fish

The main machine you choose will depend on the type of fish you farm.

The Fish Feed Extruder (For Floating Feed):

“This is the most popular and recommended type fish feed pellet machine for modern fish farming in India. It cooks the feed and makes it float on water. This is ideal for fish like Rohu, Catla, Tilapia, and many Catfish, as they are surface or column feeders. Floating feed allows you to monitor eating and reduces waste.”

The Pellet Mill (For Sinking Feed):

“This feed making machine makes dense pellets that sink. It’s the right choice if you are farming bottom-feeding species like shrimp (jhinga) or certain types of prawns and other fish.”

A Practical Checklist for Buying a Machine in India

Before you invest your money, think about these important points.

What Fish Species Are You Farming?

This is the first question. It determines if you need a machine that makes floating feed (an extruder) or sinking feed (a pellet mill).

What is the Scale of Your Farm?

This will determine the production capacity you need. This is measured in kilograms per hour (kg/hr).

What is Your Power Situation?

“Is the electricity supply in your area stable? Do you have access to a three-phase connection for a larger motor? If not, a diesel engine machine might be a more reliable option for your farm.”

Can it Handle Your Local Ingredients?

Make sure the machine can effectively process your main ingredients. This could be oily mustard cake or fibrous rice bran.

Look for Robust Build Quality and Simple Controls

“A strong machine that can handle local conditions and is easy to operate and maintain is very important for long-term use.”

Ask About After-Sales Service and Spare Parts

“Before you buy, ask the supplier a key question: ‘If I need a new screw or die, do you have it ready in stock, and can you ship it to my district quickly?’ Good service support is crucial.”

Cost & Financing Considerations in India

Typical Price Range (in Indian Rupees – INR)

Prices for these machines can vary greatly. To give a very rough idea, a very basic, small-scale machine might start from under ₹1,00,000. A good quality small extruder can be in the range of ₹1,50,000 to ₹3,00,000 or more. It is essential to get direct, current quotes from several suppliers.

Looking for Financing & Government Schemes

- You can inquire about agricultural or SME (Small and Medium-sized Enterprises) loans from major Indian banks.

- Crucially, you should look into the Pradhan Mantri Matsya Sampada Yojana (PMMSY). “This is a major government scheme for fisheries development in India.

- It often has provisions or subsidies for setting up small feed mills and for buying equipment for aquaculture. You should check the latest PMMSY guidelines with your local or state fisheries department.”

Pros and Cons of Different Feed Ingredients in Aquaculture

| Ingredient | Pros | Cons |

|---|---|---|

| Fish Meal | – High protein content, providing essential amino acids. – Contains Omega-3 fatty acids beneficial for fish growth. – Easily digestible. | – Over-reliance can lead to overfishing of certain species. – Expensive, given the growing demand and limited supply. – Can lead to a fishy taste in farmed fish. |

| Soybean Meal | – Sustainable and plant-based alternative to fish meal. – Relatively high protein content. – Economically viable due to mass production. | – Contains anti-nutritional factors which can affect fish health if not processed correctly. – Lacks some essential amino acids. – Over-reliance can contribute to deforestation. |

| Insect Meal | – Sustainable and efficient protein source. – Mimics the natural diet of many fish species in the wild. – Low environmental footprint. | – Production at scale is still in nascent stages. – Can be more expensive than traditional feeds. – Acceptance in some cultures might be a challenge. |

| Algae | – Rich in Omega-3 fatty acids. – Sustainable and can be grown in controlled environments. – Reduces the reliance on fish oils and fish meal. | – Variability in nutrient content based on species and growth conditions. – Large-scale production can be expensive. – Some species of algae might produce toxins. |

| Grains (Corn, Wheat) | – Cheap and readily available. – Can act as a carbohydrate source for energy. | – Lower protein content compared to fish meal or soy. – Might require additional supplements to fulfill fish nutritional requirements. – Over-reliance can cause digestive issues in certain fish species. |

What are the benefits of using automatic fish feed machine in India?

In India’s ever-growing aquaculture sector, employing an automatic fish feed machine offers several advantages:

1. Efficiency:

Automatic fish feed making machine in India significantly speed up the feed production process compared to manual methods, allowing for more production in less time.

2. Cost Savings:

While there’s an initial investment, in the long run, automated machines can reduce labor costs and minimize waste, leading to financial savings.

3. Uniformity:

These floating automatic fish feed machine in India ensure that each pellet or feed unit is consistent in size and composition, which is essential for the uniform growth of fish.

4. Flexibility:

Many automatic feed making machines in India come with adjustable settings, enabling producers to create different sizes and types of feed to cater to various fish species and growth stages.

5. Improved Feed Quality:

Automatic floating fish feed machines in India can maintain a steady mixing rate, ensuring that the feed’s nutrients are evenly distributed, leading to better fish health and growth.

6. Reduction in Manual Labor:

This technology reduces the need for manual operations, leading to fewer errors and a more streamlined production process.

7. Adaptability to the Indian Market:

Given the diverse aquaculture practices across India, many automatic floating feed making machines in India are designed to be adaptable, considering the specific needs of the Indian market.

What ingredients are commonly used in fish feed production in India?

Fish feed production in India relies on a blend of ingredients to ensure balanced nutrition for aquaculture. Common ingredients include:

1. Protein Sources:

Soybean Meal: A primary protein source, soybean meal is widely used because of its high protein content and digestibility.

Groundnut Cake: Another significant protein source often used in fish feed.

2. Cereal Grains:

Rice Bran: Abundantly available in India, it acts as an energy source.

Maize: A common carbohydrate source used for energy.

3. Animal Proteins:

Fish Meal: Made from processing fish, it’s a rich protein source that also enhances feed palatability.

Poultry By-product Meal: Utilizes waste from the poultry industry, providing protein and essential amino acids.

4. Fats and Oils:

Oils from sources like soybean and fish help in enhancing the energy concentration in the feed.

5. Vitamins and Minerals:

Essential for fish growth and health, these are often added in the form of premixes.

6. Binders:

Ingredients like wheat flour and starch are used to give the feed pellet its shape and help it hold together underwater.

7. Amino Acids:

Lysine and methionine, among others, are added to ensure a balanced amino acid profile, crucial for optimal fish growth.

8. Additives:

Antioxidants: To prevent rancidity of fats and oils.

Probiotics: Enhance gut health and nutrient absorption in fish.

Antibiotics: Occasionally used, though there’s a push towards reducing their use due to concerns over antibiotic resistance.

Conclusion

For Indian fish farmers, a feed making machine is a powerful investment. It helps you control costs, improve feed quality using local ingredients, and boost the profitability of your aquaculture business. By understanding your needs and choosing the right technology, you can take a major step towards a more successful and sustainable fish farming operation in India.

FAQ

1. What is the best machine for making tilapia and carp feed in India?

A: A fish feed extruder. This machine makes the floating feed that is ideal for Indian Major Carps (like Rohu and Catla) and Tilapia. Floating feed is recommended because it allows you to easily monitor how much your fish are eating. This helps to reduce feed waste.

2. How much does a small floating fish feed machine (extruder) cost in India?

A: The cost of setting up a fish feed mill plant in India can vary based on the machine’s capacity and brand. However, a good quality small-scale extruder that is suitable for a small farm might start in the range of ₹1,50,000 to ₹3,00,000. It is essential to get current quotes from different suppliers.

3. What are some good, low-cost ingredients for making fish feed in India?

A: This depends on your region. However, common, cost-effective ingredients often include agricultural by-products. These include rice bran, mustard oil cake (sarso ki khal), groundnut cake, and locally available small, dried fish which can be ground into fishmeal.

4. Can I get a government subsidy for a fish feed machine in India?

A: Yes, it is often possible. You should check the latest guidelines under the Pradhan Mantri Matsya Sampada Yojana (PMMSY) scheme. Contact your local or state fisheries department for details. They often provide financial support for setting up small feed mills.

5. Where is the best place to buy a fish feed machine in India?

A: You can find a very large number of manufacturers and suppliers on online B2B platforms like IndiaMART and TradeIndia. Also, industrial cities like Coimbatore are well-known centers for manufacturing this type of machinery in India.