| Price | 15000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Product Overview

| Production Output | 0.15-5 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley, soybean, oil seed meal, fish meal, bone meal, meat etc |

| Type | dry type and wet type |

| Final Pellet Size | 0.9-10 mm |

| Application | floating pellets |

| Used For | tilapia feed production |

Introduction

The decision to produce your own tilapia feed is a significant strategic step for your tilapia farm. You know you need a tilapia feed production line in the 500 kg to 1 ton per hour range to meet your farm’s demand.

But now you face the most critical technical decisions. Should you invest in a single-screw or a twin-screw extruder? A primary consideration is the choice between a wet-type and a dry-type system. Selecting the wrong configuration can be a costly error.

electing the appropriate system, either a wet type or a dry type, is a critical decision. An incorrect choice at this stage can have significant financial consequences.

We will break down these key technology choices in detail. Our goal is to give you the expert feed manufacturing knowledge. You need to select the most efficient and profitable tilapia feed processing line for your specific operation.

The First Big Decision: Dry Type vs. Wet Type Extrusion

Your first major choice is between a dry type and a wet type tilapia feed production plant. This decision impacts your initial cost and the production quality of your final pellet feed.

The Dry Type Tilapia Feed Production Line: A Simpler Starting Point

A dry type tilapia fish feed production line uses an dry type feed extruder. This type extruder uses high heating temperature from electricity.

The intense high temperature and high pressure and shear inside the dry type fish feed machine barrel cook the feed. It does not use a separate steam boiler or a conditioner. This setup is often suitable for the lower end of our capacity range, around 500 kg/hr for small scael.

Its main advantage is a lower initial investment because you do not have the significant cost of a boiler and steam piping. However, there is a trade-off. Without the pre-cooking from a steam conditioner, the starch gelatinization rate of raw material, like soybean meal, fishmeal, corn meal, might be lower, around 80-85%. This can result in a slightly less digestible feed pellet.

The Wet Type Tilapia Feed Production Line: The Professional Standard

A wet type tilapia feed production line includes a steam boiler and a conditioner. The conditioner is a device that uses steam to pre-cook and moisten the feed mash before it enters the wet type fish feed extruder. This is the standard for any serious commercial operation, especially as you approach the 1 ton per hour for large scale.

The pre-conditioning with steam leads to a much higher starch gelatinization rate, often over 95% for high quality tilapia fish feed. This results in a more digestible, higher-quality pellet with a better Feed Conversion Ratio (FCR). A better FCR means more profit for you in the long term.

The Second Big Decision: Single-Screw vs. Twin-Screw Extruder

Once you’ve decided on a wet or dry system, you need to choose the fish feed extruder itself.

The Single-Screw Extruder: The Cost-Effective Workhors

This fish feed machine uses one rotating screw to convey, mix, and cook the material. A single-screw extruder is excellent for standard tilapia feed formulations. These recipes usually have a moderate fat content, up to 12-15%. For a 500 kg/h to 1 t/h line that is making standard feed, this is the most common and cost-effective choice.

The Twin-Screw Extruder: For Maximum Flexibility and High-Performance Feeds

This more advanced machine uses two intermeshing screws. These provide far superior mixing and more precise control over the cooking process. You should seriously consider the higher investment of a twin-screw extruder if you plan to: Use a very wide variety of raw fish feed ingredients.

Produce very high-fat, high-energy feeds with over 17-20% fat. Make very small pellets for fingerlings (e.g., 1.0-1.5mm), where precise control is critical.

Two Reference Configurations

Lean Floating Line — 500 kg/h, Dry, Single-Screw

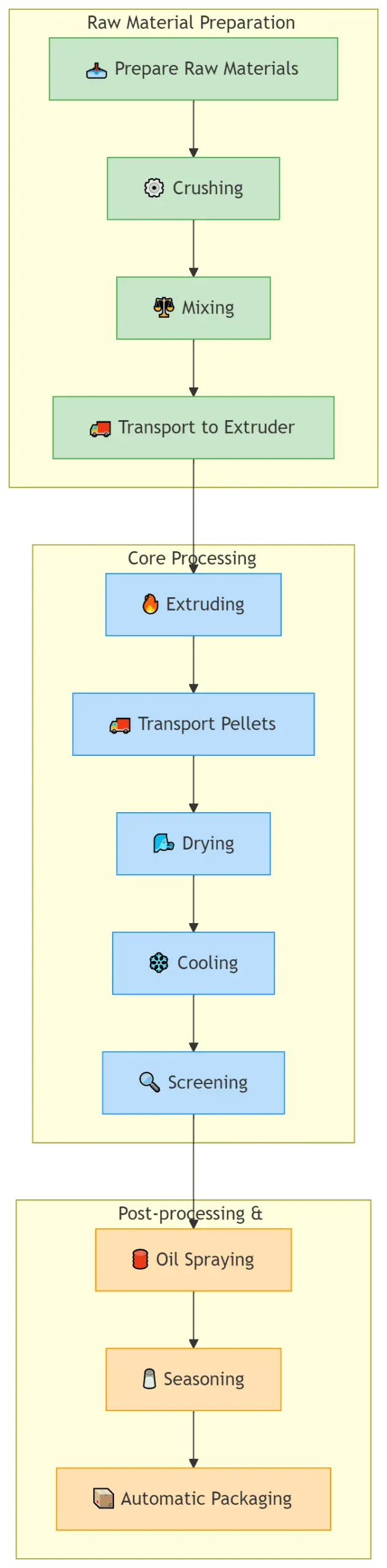

Flow: Hammer mill 22–30 kW → 500 L mixer → Water conditioning → Single-screw extruder → 2-pass dryer → Counter-flow cooler → Vibratory screener → Drum coater → Pack.

| Node | Typical spec | Purpose |

|---|---|---|

| Hammer mill | 22–30 kW; 0.5–1.0 mm screen | Grind to support PDI |

| Extruder | 55–75 kW main drive | Torque for 2–4 mm floating |

| Dryer | 2-pass; 30–60 mm bed | Moisture to 10–12% |

| Coater | Drum; 3–6% oil | Energy and dust control |

QC after tuning: Gelatinization 50–80%;PDI ≥92%;Float ≥95% at 10 min;Bulk density e.g. 360 g/L ±30 g/L(Bulk method).

Versatile Line — ~1 t/h, Wet, Twin-Screw(Floating + Sinking)

Flow: Hammer mill 45–55 kW → Twin-shaft mixer → Steam conditioner(0.3–0.6 t/h at 0.4–0.8 MPa) → Twin-screw extruder → 3-pass dryer → Cooler → Screener → Vacuum coater → Pack.

| Node | Typical spec | Purpose |

|---|---|---|

| Conditioner | Steam 0.3–0.6 t/h, 0.4–0.8 MPa | Higher cook at lower SME |

| Twin-screw | 90–132 kW main drive | Tight density; micro-sizes |

| Dryer | 3-pass; PID control | Stable 10–12% moisture |

| Coater | Vacuum up to 10–12% oil | Deep, uniform uptake |

QC after tuning: Gelatinization 50–80%;Bulk density band ±20–40 g/L;PDI ≥93%;Stability 45–60 min.

Troubleshooting

| Symptom | Likely cause | Fast fix |

|---|---|---|

| Crumbly pellets(low PDI) | Grind coarse;pre-moisture low;worn die | Finer screen;raise pre-moisture to 20–24%;inspect die |

| Weak float | Density high;SME low | Increase barrel temperature;adjust screw speed;raise starch |

| High fines after dryer | Air velocity high;bed depth high | Reduce velocity;lower bed depth;softer transfers |

| Size variation | Knife wear;feeder surging | Replace knives;stabilize feeder with PID |

FAQ

Is wet-type always superior for floating tilapia fish feed?

A wet-type system is not always necessary. While it can improve the feed’s cook and stability with less mechanical energy, a well-calibrated dry-type extruder can still meet the specifications for standard 2–4 mm floating pellets. The final decision should be based on the reliability of your steam supply and your specific product goals.

Can single-screw produce both floating and sinking pellets?

Yes. This requires careful adjustment of the moisture content, screw speed, and die configuration. For tight density bands or ≤1 mm sizes, twin-screw offers more control.

What is a realistic density tolerance to specify?

For Bulk density, ±20–40 g/L is typical on twin-screw under steady settings. The specific test method used must be clearly stated on all contracts and Certificates of Analysis (COAs).

How should starch cook be defined to avoid disputes?

Specify 50–80% gelatinization. Name the method(RVA/Enzymatic/DSC). Fix the sampling conditions(dried & cooled pellets, 10–12% moisture, ≤0.5 mm grind).

What steam capacity is suitable for a ~1 t/h wet tilapia feed production line?

Plan ~0.3–0.6 t/h of clean, dry steam at 0.4–0.8 MPa, with traps and condensate return.