| Price | 16000-60000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Product Overview

| Production Output | 0.15-5 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal, fish meal, bone meal, meat etc |

| Type | dry type and wet type |

| Final Pellet Size | 0.9-10 mm |

| Application | floating pellets or sinking pellets |

| Used For | shrimp feed production |

Introduction to Shrimp Feed Production

The production of shrimp feed has several unique requirements compared to feed for terrestrial animals. The pellets must be smaller, nutritionally dense, and must remain stable in water for couple of hours. The main challenge for a shrimp farm is to meet these targets consistently. The ability to do this is what separates an average operation from a highly profitable one. A dedicated aqua fish feed production line can help achieve these targets.

This is a technical guide for business owners. It is for those planning a serious investment in a shrimp feed production line. We will analyze the key production goals. We will also detail the required machinery and the best tilapia feed formulation strategies to create a top-quality product.

Defining Success: Key Quality Indicators for High Quality Shrimp Feed

Before looking at machinery, you must understand the final product goals. A high-performance shrimp feed is defined by these key indicators.

1. Water Stability: The Non-Negotiable KPI

Shrimp are classified as bottom feeders and are characterized by a slow rate of consumption. This means the feed pellet must remain intact in the water to prevent nutrient loss.

The industry benchmark for good quality is a water stability of ≥2 hours. Premium feeds often aim for ≥4 hours. This ensures the shrimp have enough time to find and consume the feed.

2. Low Leaching Loss: Protecting Your Nutrients

A key part of the shrimp feed production process is minimizing the loss of water-soluble nutrients. A quality pellet should have a low leaching loss test result for key proteins and vitamins. This results in greater nutrient uptake by the shrimp and reduces nutrient loss to the pond water.

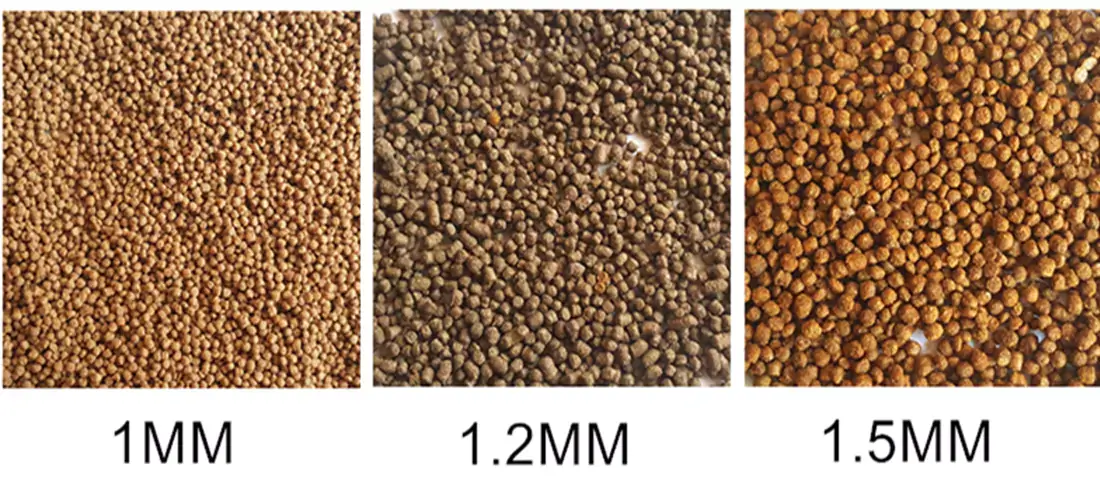

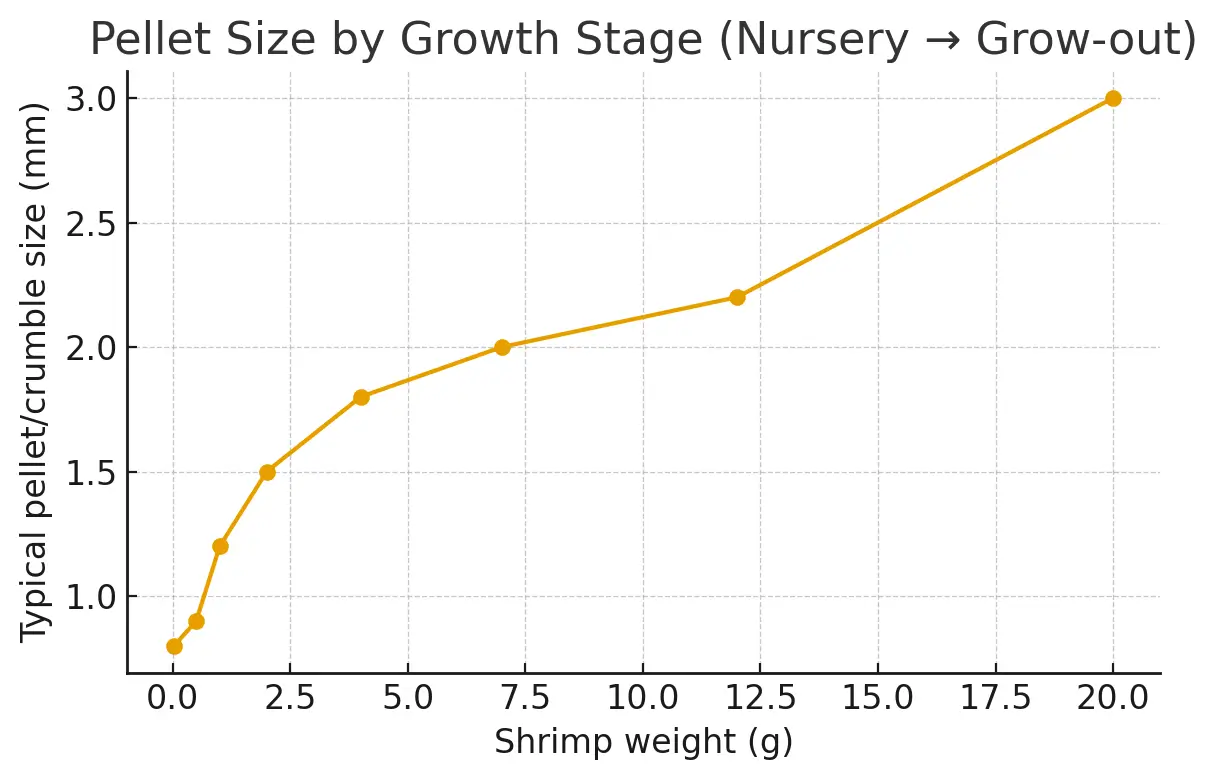

3. Precise Pellet Size Distribution

You need the ability to produce different pellet sizes. The typical range is from 0.7mm to 3.0mm. This is to match the different growth stages of the shrimp, from the nursery phase to the final grow-out (nursery→grow-out).

4. Optimal Pellet Density

The goal is to produce a dense pellet that sinks reliably. This is achieved through proper densification in the pellet mill and conditioner, not through simple compression alone.

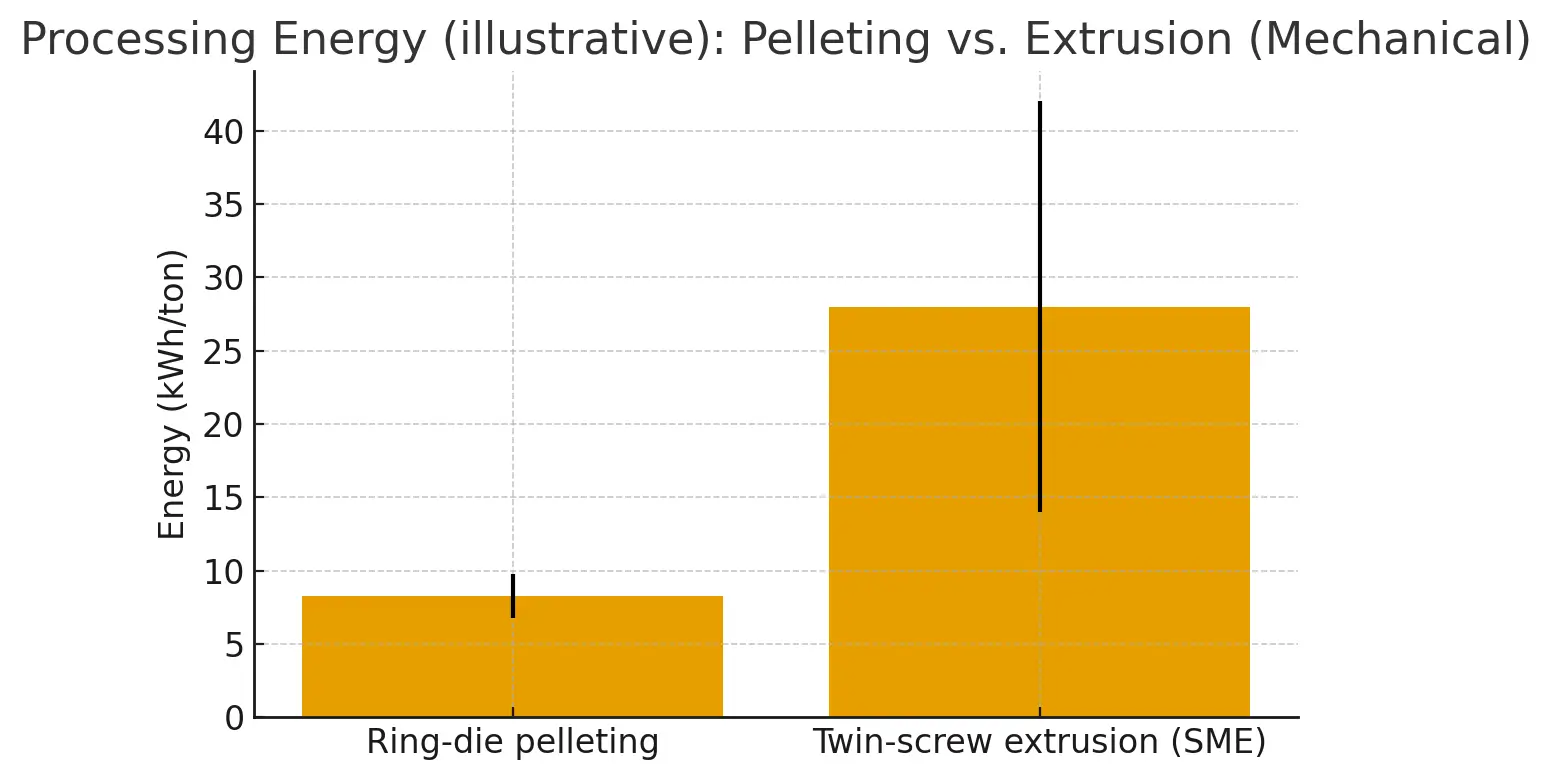

The Core Technology: Pelleting vs. Extrusion for Shrimp Feed

The Pellet Mill: The Industry Standard for Sinking Shrimp Feed

The shrimp pellet mill is a primary piece of equipment in most production lines. It is typically used with a high-quality conditioner to produce the best results. It creates the dense, sinking pellets that most shrimp species require.

The Role of Extrusion (For Nursery & Specialty Feeds)

Extrusion technology is not common for standard grow-out shrimp feed. However, it is an essential process for the nursery stage.

It is the key technology used to produce very small micro-pellets. It offers superior control over very small pellet sizes and also provides higher digestibility for very young shrimp.

The Product Densification Unit (PDU/OTD) Insider Tip:

Many high-end production lines use a Product Densification Unit (PDU) after the pellet mill. This unit’s primary function is to increase pellet density and improve water stability. This is a post-pelleting treatment that significantly improves pellet quality and hardness.

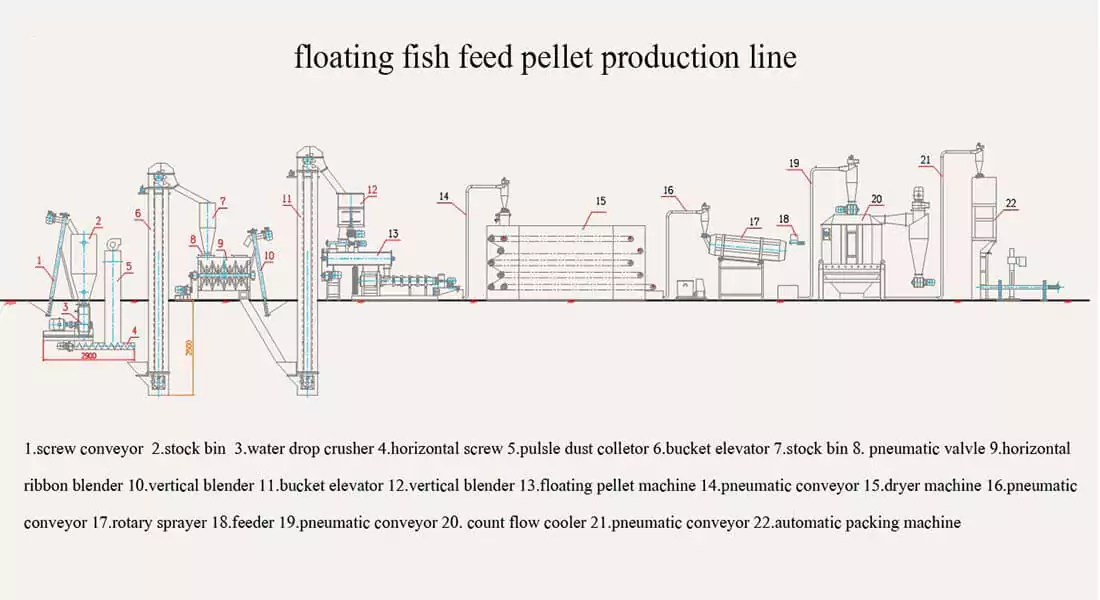

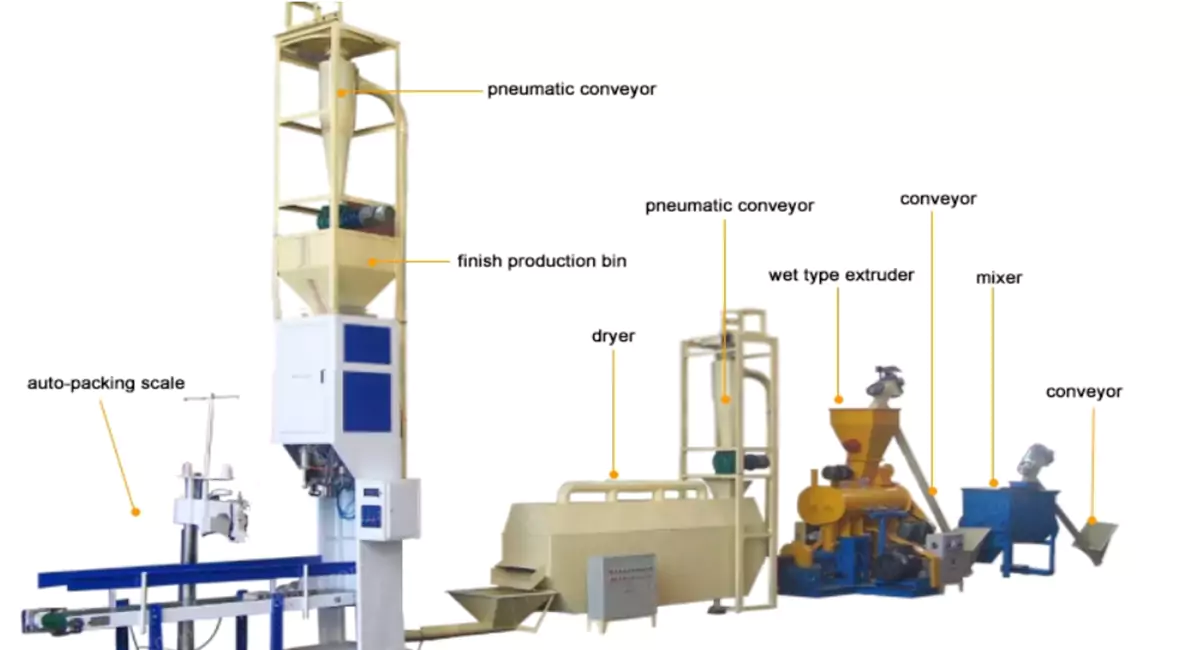

Inside the Production Line: Machinery for High-Performance Shrimp Feed

A high-performance shrimp feed pellet production line requires specialized machinery at each step.

1. The Grinding Section (Ultra-Fine Pulverizer) Expertise:

A standard hammer mill grinder is insufficient for the specific requirements of shrimp feed. The production process necessitates the use of an ultra-fine pulverizer. The raw materials, such as soybean meal, must be ground to a very fine particle size.

The target is typically 95% of particles passing through an 80-mesh screen. This creates more surface area for the ingredients to bind together, which is critical for a durable pellet.

2. The Mixing & Conditioning Section

The fish feed mixer must ensure a perfect blend of all micro-ingredients. The conditioner must then provide uniform steam hydration. This is to properly gelatinize starches and activate binders in the formula.

3. The Pellet Mill with a High-Quality Die.

The shrimp feed pellet machine used is often a ring die type. It must be robust enough to handle the high pressure needed to produce shrimp feed.

4. The Drying Section ( Mesh Type Dryer) Experience:

A mesh type shrimp feed dryer for sinking pellets is essential. It tumbles the pellets gently over several layers. This ensures even drying down to a target moisture of 10-11% without creating small cracks in the pellets. Cracks would destroy the pellet’s water stability.

5. The Coating Section (Vacuum Coater)

For adding high-value lipids and attractants after drying, a vacuum coating system for shrimp feed is the professional choice. It works by removing the air from the pores of the pellet and then drawing in the oil. This allows you to add much higher levels of fat, sometimes 5-10% more, than a simple drum coater could achieve.

6. The Screening & Packing Section.

These final steps in the production of shrimp feed ensure a uniform finished product and proper storage.

Formulation & Ingredients: The Science Behind the Pellet

Binders: The Key to Water Stability

Your shrimp feed formulation must include specific binders for shrimp feed. Ingredients such as alginate, wheat gluten, and CMC are used to help achieve the ≥2h water stability target.

Attractants: Ensuring Good Feed Intake

It is important to improve the palatability of the feed to encourage shrimp to eat. Key shrimp feed attractants like betaine and krill meal are often included in the formula.

Essential Lipids and Sterols

The formulation must address the specific cholesterol requirement in shrimp feed. This is because crustaceans cannot produce it themselves. They need it for hormone production and healthy growth.

Pigments for Health and Color

The proper astaxanthin dosage in shrimp feed is important. It helps to improve the color of the final shrimp product. It also acts as a powerful antioxidant for the animal’s health.

The Fishmeal-Free Challenge

Modern formulations often aim to create a shrimp feed formulation without fishmeal. This is done by using alternative proteins and carefully balancing the Essential Amino Acids (EAA).

A Business Perspective: Plant Layout, Cost & ROI

Sample Plant Layout & Area Requirements

A professional shrimp feed plant layout requires separate areas for raw material storage, production, and finished goods. This is necessary to comply with food safety standards like HACCP and ISO 22000 for aquafeed.

A Simplified Cost per Ton Model

The ongoing operational expenditure (OPEX) is a key part of your business plan.

| Cost Component (OPEX) | Example % of Total Cost |

|---|---|

| Raw Materials | 75-85% |

| Energy (Power & Steam) | 5-8% |

| Labor | 3-5% |

| Maintenance & Wear Parts | 2-4% |

| Depreciation (CAPEX) | 3-6% |

Investment (CAPEX) and Payback

The price of a 1tph shrimp feed line can vary significantly, but it is a major investment. A well-managed plant with a good local market can often achieve a Return on Investment (ROI) in 3-5 years.

Quality Control: The Professional’s Approach

Water Stability (WS) and Leaching Tests

As a feed producer, you can perform a simple on-farm WS test. A sample of the pellets should be placed in a beaker of water. The sample should then be observed at 30-minute intervals. A good quality pellet should show minimal disintegration or swelling.

Shrimp Feed QA/KPI Quick Reference

| KPI/Spec | Typical Target | Why it matters | Method/Source type |

| Water stability (WS) | ≥2 h (premium ≥4 h) | Shrimp grow-out; tray feeding | Bench test; Obaldo et al. protocol |

| Nutrient leaching | Track at 30/60/120 min | Protein & vitamin retention | Bench filtration/oven-dry method |

| Pellet size distribution | 0.7–3.0 mm | Nursery → grow-out | Company specs + literature |

| Grinding fineness | ≤ 250 μm common for shrimp | Improves binding & WS | Studies on particle size & stability |

| Cholesterol inclusion | 0.2–0.5% of diet | Molting/growth support | Postlarval vannamei studies |

| Astaxanthin inclusion | ≈50–100 mg/kg | Pigmentation/antioxidant | Grow-out trials |

| Binders | Alginate, wheat gluten, CMC | Raise WS; lower fines | Binder comparison studies |

| Bulk density/velocity | Match tray/pond practice | Reliable sinking | In-house SOP |

| Moisture (after drying) | ≤10–11% | Storage stability | Hot-air multi-pass dryer |

Implementing HACCP/ISO 22000

These are food safety management systems. Implementing them involves identifying critical control points in your process. This is the standard for professional shrimp feed manufacturers.

Conclusion

A high-performance shrimp feed production line is a specialized system. This process is designed to meet several unique challenges. The goal is to create pellets that are small, dense, and very stable in water.

Success requires choosing the right machinery. This includes tools like an ultra-fine pulverizer and a multi-pass dryer. It also demands a deep understanding of feed formulation and a strong commitment to quality control.

FAQ

Q: What is the main difference between a shrimp feed line and a floating fish feed line?

A: The main difference is the core shaping machine. A shrimp feed production line uses a pellet mill and often a PDU (densifier) to create dense, sinking pellets for shrimp and prawn feed. A floating fish feed line uses a feed extruder to create light, buoyant pellets.

Q: What is the most important machine for ensuring shrimp pellet quality?

A: While every machine is important, many experts would argue that the conditioner and the dryer are the most critical. Proper steam conditioning is the key to achieving good water stability. A gentle, efficient dryer is essential for preventing cracks in the final pellet after the pelletizing cooling process.

Q: How much cholesterol do I need to add to shrimp feed?

A: The specific cholesterol requirement in shrimp feed varies by species and life stage. However, a general inclusion level is often around 0.2% to 0.5% of the total diet.

Q: What is a “micro-pellet” and how is it made?

A: A micro-pellet is a very small pellet (often 0.7mm – 1.2mm) used for the nursery stage of shrimp. The shrimp feed pellet production for this size typically uses a specialized extruder, not a pellet mill. This is because extrusion offers better control over very small pellet sizes and provides higher digestibility for very young shrimp.

Q: What are the key utilities I need for a 1tph shrimp feed line?

A: A professional 1 tph shrimp feed production line has several key facility requirements.

First, you will need a reliable three-phase power supply. This often requires a dedicated transformer. You will also need a steam boiler with a capacity of at least 1-2 tons of steam per hour. Finally, the building must have adequate floor space and ceiling height to house the equipment.