| Price | 13000-80000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Floating Fish Feed Production Line Overview

| Production Output | 0.5-5 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, fish meal, bone powder, etc |

| Type | dry type and wet type |

| Final Pellet Size | 0.9-10 mm |

| Application | producing floating pellets |

| Used For | shrimp, catfish, tilapia, fish, and other aquatic feed |

floating fish feed production line video

introduction of Floating Fish Feed Production Line

For fish farmers raising species like tilapia or catfish, the high cost of quality floating feed is a major challenge. It can feel like your profits are being eaten up before your fish even take a bite. But what if you could control this cost and the quality of your feed? A floating fish feed production line is a complete system that allows you to do just that. It’s not just about making feed; it’s about taking control of your farm’s biggest expense and improving your fish’s performance.

This in-depth guide is for serious fish farmers. We’ll go beyond the basics to explain the key machines, the step-by-step process, and the critical ‘insider’ knowledge you need to make a smart investment.

What is a Floating Fish Feed Production Line?

Think of it as a specialized, automated kitchen for your fish. It is a series of industrial machines that work together in a specific order. The system takes raw ingredients like maize and soy and turns them into finished, buoyant pellets that float on water.

Its core purpose is to create a complete, nutritionally balanced, and highly digestible feed. The feed is designed to stay on the water’s surface, which allows your fish to eat it efficiently. This floating fish feed production line can make feed for different aquatic like catfish feed, shrimp feed, tilapia feed etc.

What is the Advantages of Floating Feed (Why It’s Worth It)

Using extruded floating feed offers powerful advantages for your fish farm.

You Can See Your Fish Eat (Better Feed Management)

This is a huge benefit. Because the pellets float, you can visually monitor the feeding activity of your fish. This helps you to prevent wasteful overfeeding. It also helps you ensure that all your fish are getting enough food.

Drastically Reduces Feed Waste and Improves Water Quality

Floating pellets are not lost in the mud at the bottom of the pond. This means a much higher percentage of the feed you produce is actually consumed by your fish. This saves you money and helps prevent water pollution from uneaten feed that decomposes.

Better Digestion and Faster Growth (The Science of Extrusion)

The cooking process inside the extruder causes starch gelatinization. This simply means the starches in the feed are cooked and broken down. This makes the carbohydrates much easier for the fish to digest and absorb. This often leads to a better Feed Conversion Ratio (FCR) and faster, more uniform growth.

Improved Feed Hygiene and Safety

The intense heat and pressure of the extrusion process also help to kill harmful bacteria that might be present in the raw ingredients. This results in a safer, more hygienic feed for your fish.

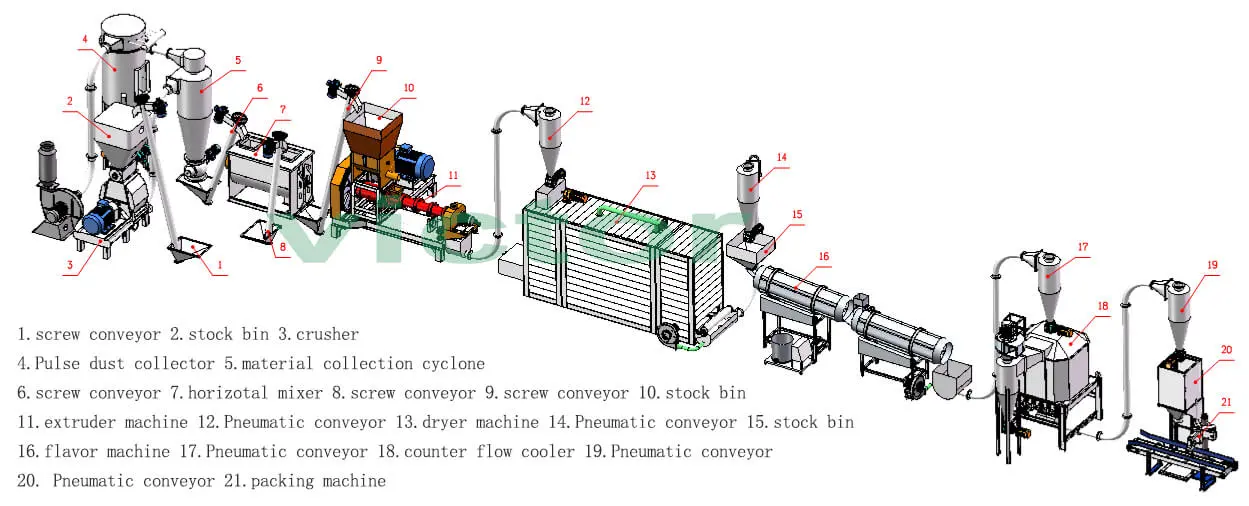

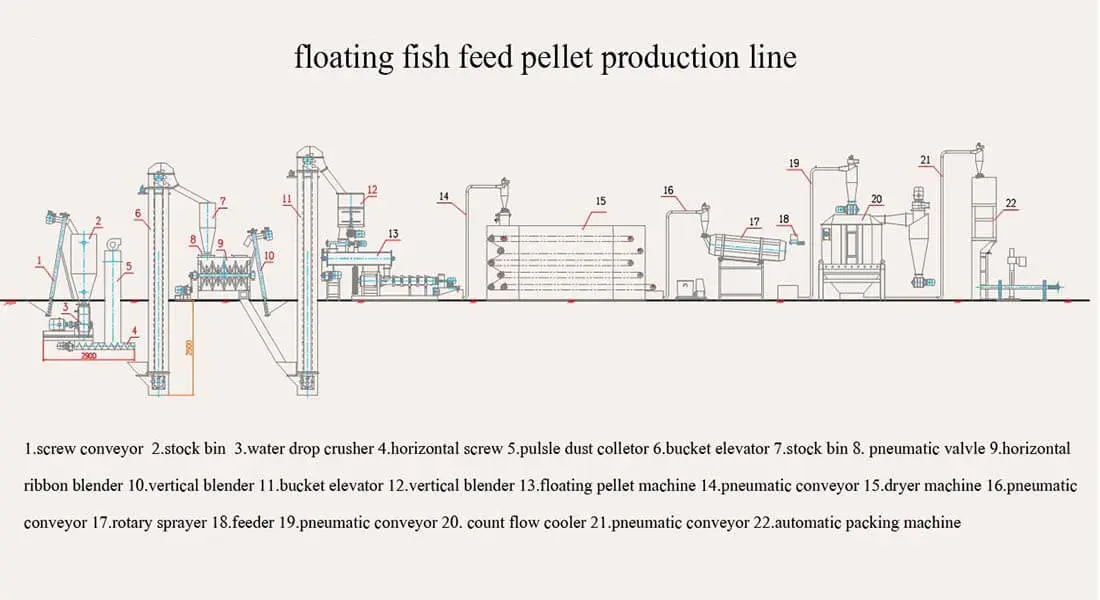

the Key Machinery Inside the fish feed Line

Each machine in a floating fish feed production line has a vital role to play.

The Grinding Section (Hammer Mill): Why a Fine Powder is Critical.

This fish feed grinder machine job is to grind raw ingredients into a uniform powder. The right particle size is critical. It helps the fish digest the feed easily and helps form a strong, quality pellet.

The Mixing Section (Mixer): The Secret to a Balanced Pellet.

A fish feed mixer machine job is to blend all the ground ingredients and tiny supplements perfectly. This ensures every single pellet is a complete and balanced meal. An uneven mix means uneven nutrition for your fish.

The Extruder: The Heart of the Floating Fish Feed Production Line.

This is the special floating feed pellet machine that cooks the feed under high pressure, causing it to expand and float. A standard pellet mill cannot do this. It is the most important machine in the production line.

The Dryer: The Most Important Step for Storage.

The extrusion process adds a lot of moisture to the feed. A fish feed dryer is essential to remove this moisture. This prevents mold and spoilage, allowing you to store the feed safely.

The Coating Section (Coater): Adding Extra Energy and Flavor.

After drying, a coater can spray the pellets with oils or fats. This adds energy and can make the feed more appealing to the fish.

The Cooling & Packing Section: The Final Steps.

A cooler brings the pellets down to room temperature to harden them. A packer then weighs and bags the feed for easy handling.

Requirement of Powder Raw Materials

| die size (mm) | powder fineness required |

| 1.0 | 95% at 90-100 mesh |

| 1.5 | 95% at 80 mesh |

| 2.0 | 95% at 80 mesh |

| 3.0 | 95% at60 mesh |

| 4.0 | 95% at 60 mesh |

| 5.0 | 95% at 60 mesh |

The Production Process: From Raw Ingredient to Floating Pellet

Here is a general look at the steps in a modern feed plant:

- Receiving & Quality Control of Raw Materials.

- Grinding the fish feed ingredients to a fine, consistent powder.

- Batching & Precise Mixing of the formula.

- Extruding (The main cooking and shaping step).

- Drying the pellets to the correct moisture level.

- Coating with oils or other liquids.

- Cooling the pellets to harden them.

- Bagging the finished product.

How to Choose the Right floating fish feed Production Line

Here are some simple questions to ask yourself when choosing a system.

How big is your fish farm?

This will help you decide what capacity you need. Capacity is measured in how many kilograms the line should make per hour. At first you can choose small productin plant, as long with your business increased, you can scale up your fish feed production.

What is your power source?

Do you have a reliable three-phase electrical supply for the large motors in the line? If not, you may need to consider a system with diesel engines.

Look for a strong and simple system.

Choose a floating fish feed production line that is well-built. It should also be easy to operate and maintain.

Ask about after-sales support.

Make sure the supplier can provide technical help. They should also have spare parts if you need them in the future.

What to Look for in a Fish Feed Production Line

When you are ready to invest, ask these important questions.

What is the Real Capacity for Your Fish Feed Formula?

“Don’t just look at the advertised number. Ask the supplier for the machine’s capacity based on a typical fish feed recipe, which contains proteins and fats. This is often different from its capacity with easy-to-process corn.”

What is the Quality of the Extruder’s Screw and Barrel?

“These are the high-wear parts of the machine. They must be made from a high-quality, wear-resistant alloy steel to handle the intense pressure and abrasion for a long time.”

How Efficient is the Dryer?

“A good extruder is useless without a good dryer that can keep up with its production and dry the pellets evenly. Make sure the dryer is sized correctly for the extruder’s output.”

What Level of Automation and Control Do You Need?

Think about the difference between simple control panels and more advanced PLC systems. More automation can improve consistency but also increases the cost.

Ask About After-Sales Service and Spare Parts.

“A breakdown can be a disaster for your feeding schedule. Ask the supplier directly: ‘If my extruder’s screw wears out, how quickly can I get a replacement?'”

Mistakes You Have to Avoid

- Your Grinder is Just as Important as Your Extruder. “You cannot put coarsely ground material into an extruder and expect good results. For the extruder to work properly, your raw ingredients must first be ground into a very fine, consistent powder. A good grinder is a necessary partner to a good extruder.”

- Ignoring the Importance of the Dryer. “The number one mistake beginners make is underestimating the dryer. Pellets come out of the extruder hot and very moist. If you do not dry them properly and quickly, you will end up with a pile of moldy, unusable feed. A good dryer is not optional; it is essential.”

- Start with a Simple, Proven Formula. “Don’t try to invent a complex new recipe on day one. Get a good base formula from a trusted source, like an aquaculture extension service. Perfect your production process with that formula first. You can always get more advanced later.”

Conclusion

A floating fish feed production line is a complete, integrated system. Its core is the fish feed extruder, which cooks and expands the feed. This process creates the buoyant, highly digestible pellets that are ideal for modern aquaculture. While it is a significant investment, a well-planned production line gives you full control over your feed costs and quality. This is a key factor in running a profitable fish farm.

FAQ About Fish Feed Production Line

1. What is the main machine that makes fish feed float?

A: The fish feed extruder. It works like a high-pressure cooker that cooks and expands the feed mixture, trapping air inside the pellets and making them float.

2. What is the difference between a floating feed production line and a sinking feed line?

A: The main difference is the core shaping machine. A floating feed line uses an extruder. A sinking feed line uses a simpler, less expensive machine called a pellet mill, which only compresses the feed.

3. Do I need all the machines in a floating fish feed production line to start?

A: To make good quality, storable floating pellets, you at least need the core machines: a grinder, a mixer, an extruder, and a dryer. The other machines, like a coater and packer, make the process more efficient but can sometimes be added later.

4. Why is extruded floating feed often more expensive than sinking feed?

A: The extrusion process itself is more complex and uses more energy than standard pelleting. The extruder machines are also more expensive to buy and maintain. This higher manufacturing cost is reflected in the final price of the feed.

5. What is the most important factor for making high-quality floating feed?

A: While every step is important, two factors are critical: 1) A very fine grind of your raw materials, and 2) Precise control over the temperature and moisture during the conditioning and extrusion process. Getting these right is the secret to producing a well-expanded, durable floating pellet.