| Price | 500-20000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Product Overview

| Production Output | 0.1-5 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal, fish meal, bone meal, meat etc |

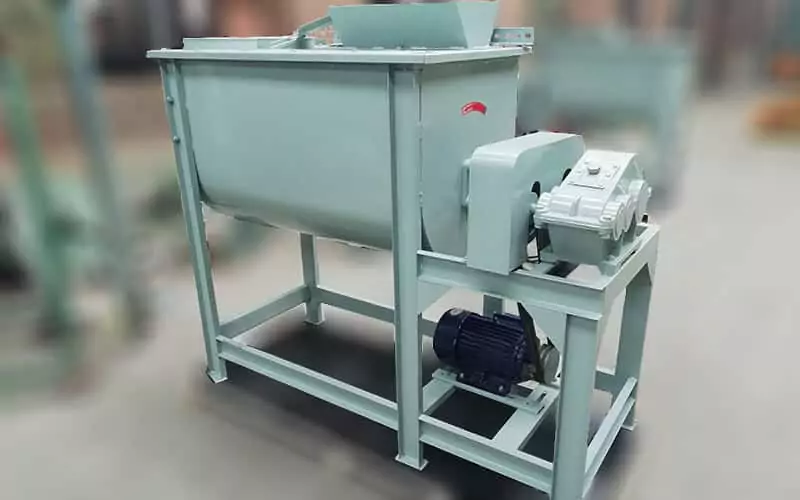

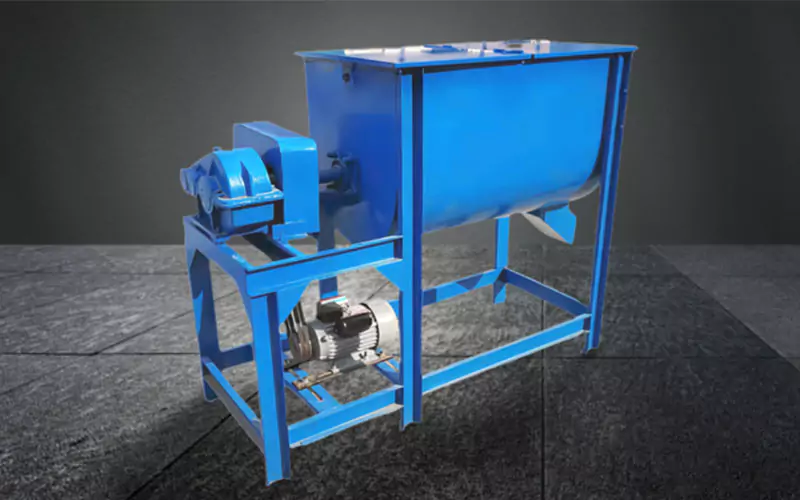

| Type | Horizontal |

| Final product size | 0.4-10 mm |

| Application | mixing powder |

| Used For | aquatic feed production |

specification of Fish feed mixer machine

electric power

| Model | Electric Power(kw) | Output(kg/h) |

| VTHS-100 | 3 | 100-300 |

| VTHS-150 | 4 | 150-450 |

| VTHS-250 | 5.5 | 200-800 |

| VTHS-500 | 7.5 | 1000-1500 |

| VTHS-1000 | 15 | 1500-3000 |

| VTHS-2000 | 18.5 | 2000-5000 |

diesel engine power

| Model | Diesel Engine Power(HP) | Output(kg/h) |

| VTHS-100 | 4 | 100-300 |

| VTHS-150 | 5 | 150-450 |

| VTHS-250 | 7 | 200-800 |

| VTHS-500 | 10 | 1000-1500 |

| VTHS-1000 | 20 | 1500-3000 |

| VTHS-2000 | 25 | 2000-5000 |

Understanding Fish Feed Mixer Machines: A Key to Quality Feed

If you’re making your own fish feed, you know that using good fish feed ingredients is just the start. To ensure every fish gets a healthy, balanced meal, those ingredients need to be perfectly mixed. That’s where a fish feed mixer machine comes in. It’s a vital piece of equipment for any aquaculture farm aiming to produce top-quality feed.

This machine takes all your separate feed ingredients – like ground grains, protein meals, vitamins, and minerals – and blends them into a single, uniform mixture or “mash.” This perfectly mixed mash is then ready for the next step, which is usually going into an extruder to be formed into pellets.

Why mixing is different for aquafeed?

Mixing feed for aquatic species presents a different set of challenges compared to feed for poultry or livestock. The process requires a higher level of precision due to the aquatic environment.

Water Stability is the Top Priority

The number one goal for aquafeed is water stability. An uneven mix of binders or oils will cause pellets to soften and crack in the water. This leads to the leaching of valuable nutrients into the pond instead of being consumed by the fish.

High Fat Content Requires a Different Strategy

Aquafeed typically has a much higher fat content. To ensure the best pellet integrity, operators should apply fat using a two-step process. First, operators add only a small amount of oil to the initial mix to aid in processing. Second, they apply the majority of the required fat after the pellet is formed through a process like oil coating.

Controlling Float and Sink Behavior

Whether a pellet floats or sinks depends on its final density and porosity. Achieving these precise targets requires the feed mash to be perfectly uniform before it enters the fish feed pellet extruder.

Impact on Water Quality

Poorly made pellets create excess fine particles and nutrient loss in the water. This can overload filters in a Recirculating Aquaculture System (RAS) or fuel algae blooms in ponds. A high-quality fish feed mixing process is the most cost-effective tool for protecting your water quality.

Common Types of Fish Feed Mixers for Aquaculture

There are a few main types of feed mixer machine used in fish feed production. Each works a bit differently and is suited for different needs:

Ribbon Fish Feed Mixer:

How it works: This type uses a horizontal trough with inner and outer helical “ribbon” blades. These ribbons spin and move ingredients in opposite directions, creating a very thorough and fast mixing action.

Best for: Mixing dry powders, granules, and even some slightly sticky ingredients very quickly and evenly. They are a popular choice for achieving a high degree of mix uniformity.

Considerations: Ribbon feed mixer machines are very effective but can sometimes be more expensive than other types.

Paddle Fish Feed Mixer:

How it works: Paddle mixers also have a horizontal trough, but instead of ribbons, they use a series of paddles mounted on a rotating shaft. These paddles gently lift, scoop, and tumble the ingredients.

Best for: This type is often considered gentler, making it good for more delicate ingredients that might break down in a more aggressive mixer. It can also handle the addition of liquids (like oils) quite well.

Considerations: Mixing time might be a bit longer compared to a ribbon aquafeed mixer to achieve the same level of uniformity. They are often a good, cost-effective option.

Vertical Mixer (Often a Screw Mixer):

How it works: A large vertical screw auger is typically in the center of a cone-shaped bin. The screw lifts ingredients from the bottom and drops them at the top, allowing gravity to help with the mixing action as the material cascades down.

Best for: Often used for mixing larger batches of free-flowing dry ingredients. They can be a good choice for simpler mixing tasks in bigger operations.

Considerations: Achieving a perfectly uniform mix for ingredients with very different densities or particle sizes can sometimes take longer or be more challenging compared to horizontal mixers.

working video

A Fish Farmer’s Checklist: How to Choose the Right Fish Feed Mixer

Here are some key things to think about before you buy a fish feed blender machine:

What is Your Batch Size (in kg)?

Match the mixer’s capacity to the amount of feed you usually make at one time. Don’t get one that is too small for your needs, as this means extra work. A fish feed mixing machine that is too large for your batches might not mix small amounts well.

What Are Your Ingredients (Mainly Dry Powders or Adding Liquids)?

If your fish feed formula requires you to add a significant amount of fish oil or other liquids, a paddle fish feed mixer might be a better choice for you than a standard ribbon mixer.

What is Your Target “Mixing Uniformity”? (Ask about the CV)

For high-performance fish feed, you want a very uniform mix. You can ask suppliers what the Coefficient of Variation (CV) of their mixing machine is. A lower CV percentage is better. For good fish feed, you should aim for a CV under 7%. This is a sign of a high-quality mixer.

What Material is the Mixer Made From?

Look for stainless steel, especially for all the parts that will touch the feed. Fish feed ingredients, with their added salts, fats, and minerals, can cause regular steel to rust over time. Stainless steel resists rust. It is also much easier to clean thoroughly between different batches.

How Easy is it to Clean Completely?

A mixer that is hard to clean can lead to big problems. Old feed can get stuck inside and grow mold. This can contaminate your fresh batches. Look for models with large access doors or hatches that make cleaning much easier.

Mixing Implications for Different Aquafeed Pellet Types

The specific type of pellet you are producing—whether floating, sinking, or slow-sinking—has a direct impact on the required precision of your mixing process.

Floating Pellets

For floating fish feed pellets, it is critical to maintain a tight particle size distribution. An uneven mix of oil or binders can create dense spots within a pellet. These “density pockets” will negatively affect the pellet’s buoyancy and its durability.

Sinking Pellets

For sinking fish feed pellets, a uniform distribution of binders and oil is essential. This prevents the pellet’s edges from eroding and stops premature cracks from forming when it is in the water.

Slow-Sinking Pellets

Slow-sinking fish feed pellets have the most demanding requirements and the narrowest operational window. Their production requires the use of a multi-point spray system for liquid addition. You must also verify the Coefficient of Variation (CV) more frequently, especially when changing the batch size.

Frequently Asked Questions

1. How much oil should be added in the fish feed mixer versus after pelleting?

It is best to keep the amount of oil added in the initial pre-mix to a low, single-digit percentage. This small amount aids in the processing of the mash. The majority of the required oil should be applied after the pellet is formed, using a post-coater or a vacuum coater. This method ensures better pellet durability and a more uniform surface coverage.

2. Does a better mix automatically guarantee good water stability?

A good mix is necessary, but it is not the only factor. Water stability also depends on the type of binder used, the degree of starch gelatinization during cooking, and the final cooling process. However, a poor mix is a very common cause of failure. It almost always results in early nutrient leaching and pellets with fragile, easily broken edges.

3. What CV target is required for sensitive additives like pigments or medications?

For these critical, low-inclusion additives, you must be stricter than the standard target. You should aim for a Coefficient of Variation (CV) of 5% or less. Operators must also validate this result by using an increased number of sampling points. This step is critical to ensure the highest possible distribution uniformity for these potent ingredients.

4. Should I choose a paddle mixer or a ribbon mixer for aquafeed?

The choice depends on your specific formula. A paddle fish feed mixer is the better option when you need to add liquids in stages or if you need to protect fragile particles in the mix. A ribbon fish feed mixer is generally faster and more efficient for dry blends that require only a light, final addition of oil. The best choice is the machine that can consistently achieve your target CV at your standard batch size.