| Price | 500-10000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Product Overview

| Production Output | 0.1-5 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal,fish meal, bone powder, grass meal, etc |

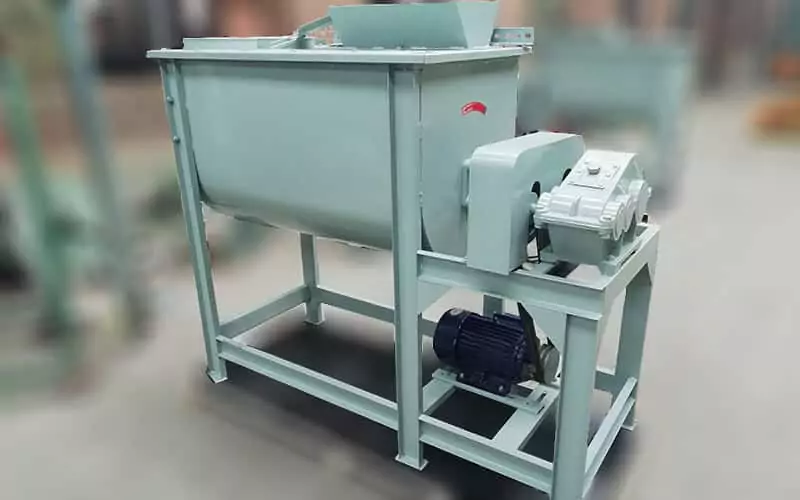

| Type | Horizontal Ribbon |

| Final product size | 0.4-10 mm |

| Application | mixing powder materials |

| Used For | chicken feed production |

specification of chicken feed mixer machine

electric power

| Model | Electric Power(kw) | Output(kg/h) |

| VTHS-100 | 3 | 100-300 |

| VTHS-150 | 4 | 150-450 |

| VTHS-250 | 5.5 | 200-800 |

| VTHS-500 | 7.5 | 1000-1500 |

| VTHS-1000 | 15 | 1500-3000 |

| VTHS-2000 | 18.5 | 2000-5000 |

diesel engine power

| Model | Diesel Engine Power(HP) | Output(kg/h) |

| VTHS-100 | 4 | 100-300 |

| VTHS-150 | 5 | 150-450 |

| VTHS-250 | 7 | 200-800 |

| VTHS-500 | 10 | 1000-1500 |

| VTHS-1000 | 20 | 1500-3000 |

| VTHS-2000 | 25 | 2000-5000 |

Overview

Modern poultry diets need micro-ingredients to be mixed just right. You need a high-quality poultry feed mixer machine that always gets a low Coefficient of Variation (CV).

This keeps your flock’s performance up. It also gets rid of the expensive practice of over-formulation. In this case, producers add extra, expensive ingredients to make up for a mix that isn’t always the same.

This guide focuses on mixing powdered chicken feed ingredients, such as base grains, protein meals, and vitamin premixes. We will cover why certain mixer types are effective, the correct sampling procedures to verify your CV, and key operational details.

Key Outcomes of a Quality Mixing Process:

- A validated Coefficient of Variation (CV) of 5–7% or less for even nutrient distribution.

- Fast and repeatable batch times, typically 3–8 minutes.

- Easy cleaning between different feed formulas, supported by stainless steel parts and tool-free access.

- Effective for poultry mash and premixes, including the addition of small amounts of oil (0.5–3%) via a spray system.

Explore our full feed mixer machine range for other poultry and animal feed.

Why This Chicken Mixer for Poultry Mash

Because of its unique design features, this type of chicken feed mixer machine works very well for poultry mash.

It makes sure that all of the micro-ingredients, such as vitamins, minerals, and medicines, are evenly spread out. Bi-directional ribbons or staged paddles are used in the chicken feed blender.

This design makes a convective mixing action that gives a low and predictable Coefficient of Variation (CV). A spray bar breaks up oil into very small droplets, which is good for adding small amounts of oil. This stops clumps from forming and makes sure the coating is even.

Our engineers also make sure that the chicken feed mixing machine works in a clean way. They have a smooth U-trough shape with few dead zones, which keeps material from getting stuck. Quick-open doors make it easy to clean thoroughly and quickly.

The parts that touch the feed are made of stainless steel (SUS304 or SUS316) for better hygiene. Dealing with rations that are more fibrous?

CV Targets & Sampling SOP

Standard Operating Procedure: Mix Uniformity Verification

To make sure that each batch of feed is the same, operators must follow a strict testing process. This makes sure that the final product is of high quality and consistent throughout.

Quality Target: Coefficient of Variation (CV)

A validated ingredient’s main quality goal is a Coefficient of Variation (CV) of 5% to 7% or less. A low Coefficient of Variation (CV) means that the mix is well-blended and even, according to professional standards.

Sampling Protocol

A systematic sampling plan is required for each batch test.

- Sample Collection: You need to take at least 10 samples from different places in the mixer. This should cover the top, middle, and bottom of the batch, as well as the area near the discharge point.

- Sample Handling: To keep the samples safe, the operator must seal them all right away. Your quality assurance plan will then tell you if you should test the samples one at a time or all together.

- Measurement Accuracy: To lower the chance of making a mistake when measuring, the operator must use calibrated scales for all weighing. The operator must also use all of the test methods in the same way every time.

Verification Schedule

In a few important situations, the quality control plan says that operators must do a CV verification test. They have to do this test when they use a new feed formulation, change the batch size, do major maintenance on the mixer, and as part of their regular weekly quality checks.

The Correct Loading Procedure for a Uniform Mix

To get a smooth mix, it’s very important to add the ingredients to the chicken feed mixer machine in the right order. Following the right order makes sure that all the parts, especially the micro-ingredients, are spread out evenly.

Standard Addition Order

A proven and effective loading sequence is as follows:

- First, add the base grains and flours, which make up the bulk of the volume. For optimal CV, pre-grind cereals with a chicken feed grinder (typical screens 0.8–2.0 mm depending on formula).

- Second, add the protein meals and by-products.

- Third, add the micro-premix, which contains the essential vitamins, minerals, or any applicable medications.

- Finally, any micro-oils should be added via a spray bar during the final phase of the mixing cycle.

Expert Tips for Better Distribution

For the best results, consider these two professional tips.

First, you should add your micro-ingredients in stages. This means that you should divide your premix into two or three smaller parts and add them at different times while you are mixing. This method makes a big difference in how well they distribute in the end.

Second, if adding oil, ensure the spray is fine and steady. You must avoid simply pouring the oil in, as this can create clumps and will not coat the particles evenly.

How to Select a Chicken Feed Mixer

Batch size & fill window

The chicken feed mixer machine should be sized to operate at 70–80% of its working volume under normal load conditions. Oversized units operate underfilled, increasing CV and wasting energy; too small results in additional cycles.

Ingredients & liquids

Dry powders → Ribbon first choice. If you routinely add 0.5–3% oil/molasses, a Paddle is steadier—fit a spray bar with fine atomization and a steady rate. For aquafeed formulas with higher lipid levels, consider our aquafeed mixing solutions.

Uniformity target (CV)

Make CV ≤ 5–7% your QA goal. Select a model that uses your batch size and formula and can complete it in 3–8 minutes.

Sanitation & changeover

If you change your parts often, you should choose SUS304/316 contact parts, quick-open access, and a design that cleans in less than 10 minutes.

Controls & dosing

Want to micro-dose or use an oil spray? Check that the spray-bar ports are there and that the load cells and recipe memory are working.

Footprint & power

Make sure the footprint, headroom, and power (like 380V/50Hz or 480V/60Hz) are right for your line.

Budget & TCO

Don’t just look at the sticker price; the total cost of ownership includes the cost of energy per batch, the life of wear parts, and the time it takes to clean out.

FAQ About Chicken Feed Mixer Machine

1. What is an acceptable Coefficient of Variation (CV) for poultry mash?

For a key ingredient, the majority of professional quality assurance programs aim for a Coefficient of Variation (CV) of 5% to 7% or less. Always make sure your specific goal is in line with your internal quality standards and any applicable local regulations.

2. Can I add liquids like molasses or oil in this type of mixer?

Indeed. During the last stage of the mixing cycle, you should add liquids using a spray bar for optimal results. It is crucial to check the machine’s technical specification sheet to confirm the maximum percentage of liquid that can be added in a single pass.

3. Do very small batches mix as effectively as larger ones?

Not all the time. When the poultry feed mixer machine is running with a low fill level, the Coefficient of Variation (CV) can go up. Always use the machine within the recommended fill volume for your model to get the most even and consistent mix.

4. How often should I perform a CV verification test?

You should do a CV test every time you change the standard batch size or add a new feed formulation. It is also very important to do this after any major work has been done on the poultry feed mixer machine. Regular weekly spot checks are also a common way to make sure quality control is good.

5. Can the same chicken mixer be used for both layer and broiler feed?

Yes, one chicken feed mixer machine can make feed for both layers and broilers. But you need to keep separate Standard Operating Procedures (SOPs) for each recipe.

This includes rules for the order in which ingredients should be added, the total fill volume, and the amount of time that must be spent mixing. You should also check the CV for each formula that is different.

Planning a turnkey setup? See our poultry feed production line with mixing, dosing, pelleting, cooling, and bagging.