| Price | 12000-60000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Full Containers |

| Guarantee | 1 Year |

| Shipping | By Sea |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Product Overview

| Production Output | 0.15-5 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley, soybean, oil seed meal, fish meal, bone powder, etc |

| Type | dry type and wet type |

| Final Pellet Size | 0.9-10 mm |

| Application | floating pellets |

| Used For | aqua feed production, fish feed production |

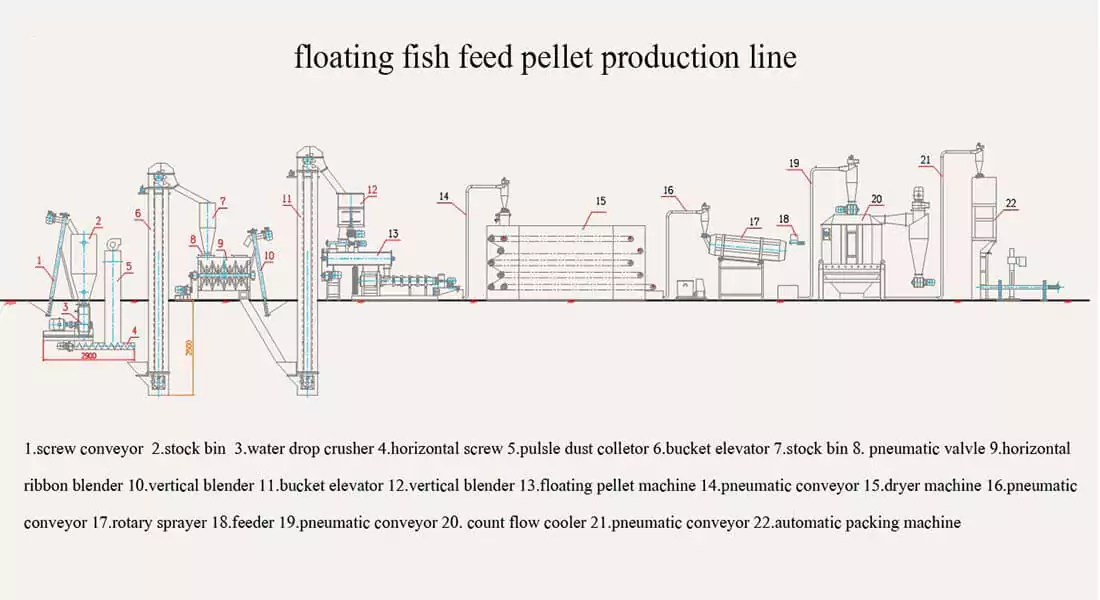

What is the Aqua Fish Feed Production Line

An aqua fish feed production line is an aquatic feed making system. It can give you the power to produce nutrition-rich food for your aquatic animals. It’s not like a single machine, it is a more compact, automated feed processing plant. It starts with raw materials crushing and ends with a finished, nutritious aqua feed pellets.

Production Process, Equipment and Key Parameters

Below is a condensed, practical view that combines process steps with the machines you need and typical target parameters.

| Step | Key equipment | Typical targets / purpose | Picture |

|---|---|---|---|

| Grinding | Hammer mill / water-drop grinder | Particle size ≤ 3 mm for even mixing and good pellet integrity |  |

| Mixing | Ribbon or paddle mixer | Uniform blend (target CV ≤ 5%) so every pellet contains the same nutrients |  |

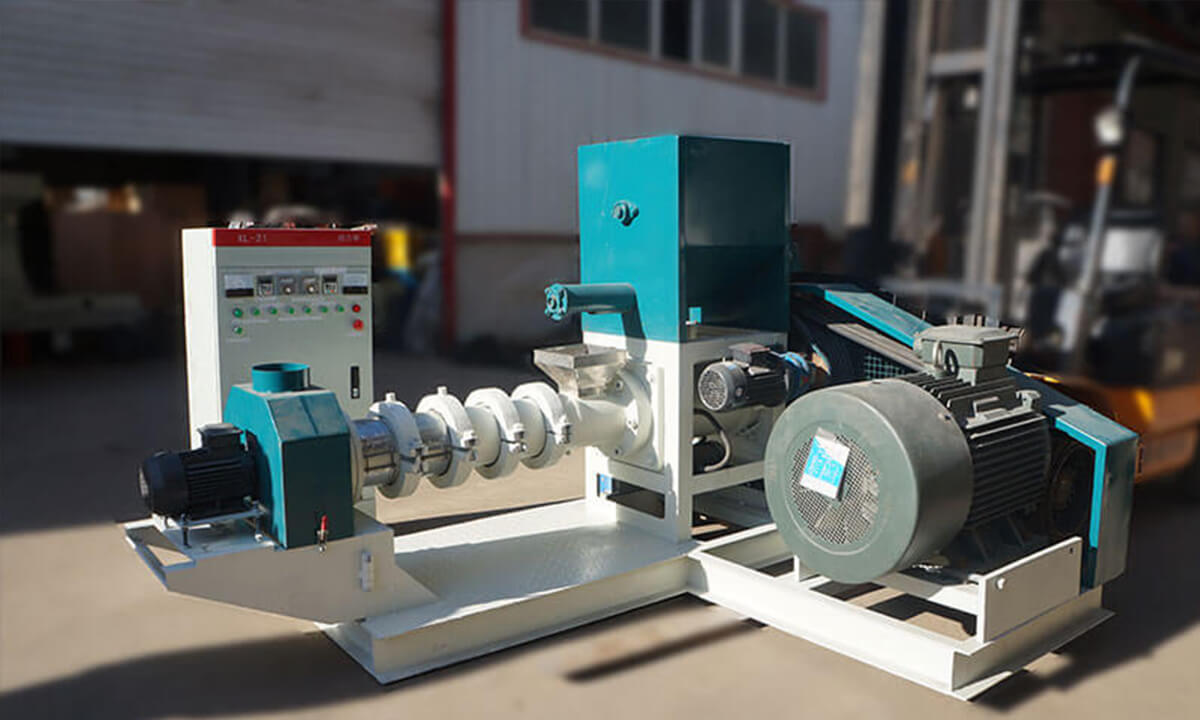

| Conditioning & Shaping | Extruder (floating feed) or pellet mill (sinking feed) | Extrusion temp ~130–150°C; forms pellets, cooks/starch-gelatinizes and reduces pathogens |  |

| Drying | Belt or mesh dryer | Reduce moisture from ~20–25% (fresh) to <10% (storage stable) |  |

| Cooling | Counterflow cooler | Lower pellet temperature to ambient to prevent condensation in bags |  |

| Coating (optional) | Oil coater | Add energy, attractants or protective coating to improve palatability & water stability |  |

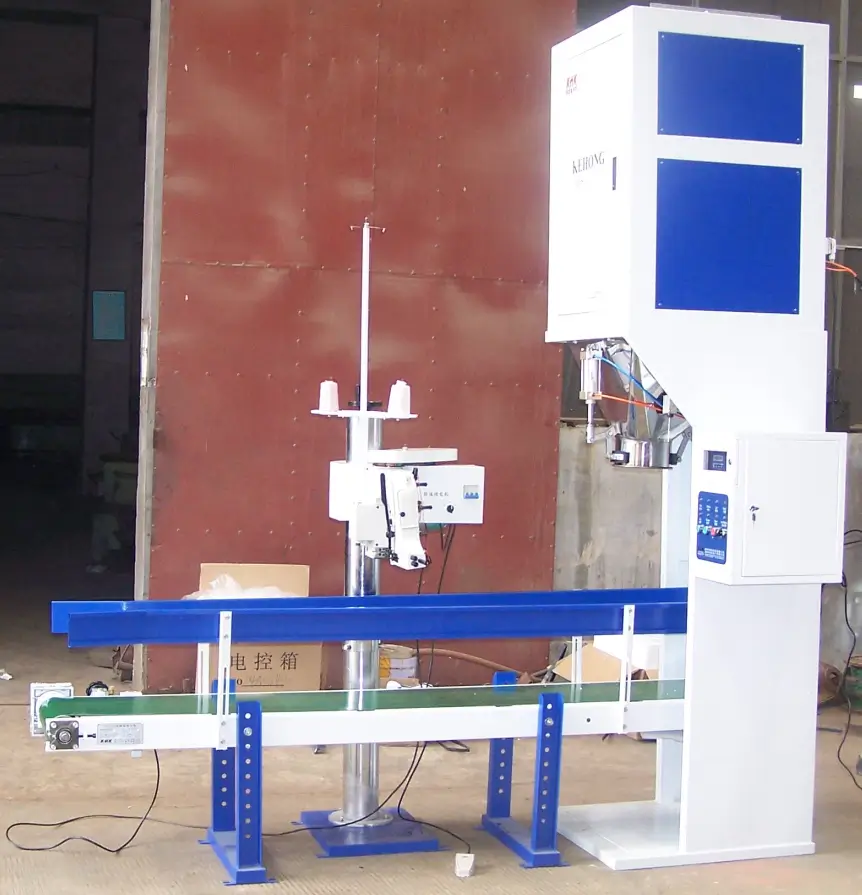

| Screening & Packing | Sifter + automatic bagger | Remove fines, weigh and pack finished product |  |

Design note: Match upstream and downstream capacities, for example extruder output vs. dryer evaporation rate—to avoid bottlenecks. Always request supplier performance data measured on a realistic, high-fat or mixed formulation rather than on “easy” materials like plain corn.

Working Video of Aqua Fish Feed Production Line

Why You Need Aqua Fish Feed Production Line

If you’re in the fish farming business, you’re familiar with the daily grind. You have to strive for faster growth and better health of aquatic, but you always have to keep an eye on the bottom line. For years, you have relied on commercial aquatic feed for catfish, shrimp, and tilapia felt like a risky trade-off. We gained convenience, but lost control over nutrition and costs.

That is why we manufacture the dedicated and specilized aquatic systems for on-farm feed manufacture for each species. They are like catfish feed production line, shrimp feed production line, and tilapia feed production line. You can not only get convenience, but also you can control the nutrition of the feed.

So our floating feed production plant is becoming more powerful equipment for modern aquatic farms. It is not just about making pellets, but also about full control of your farm future.

Actually Custom Nutrition

The real worth is to customize nutrition according to your specific fish. Different species has different needs. Your tilapia might thrive on a floating pellet high in plant protein. Industry standards show that a tilapia grower feed is most effective with a protein content of around 25-35%.

While your catfish need a dense, sinking pellet that can sink to the bottom of water. Sinking pellet with a protein level typically in the 28-36% range for optimal growth. You can use the aqua feed production plant to make both types of pellets.

Our advanced feed extruder machines are the heart of this production process. They puff the feed with high heating temperature and pressure to cook the feed during extrusion: it makes the starches easier to digest for fishes. This extrusion process increases the digestibility of starches in the feed from as low as 20-40%,in some studies, the rate can be or over 90%.

This means your fish can get more energy and protein from each bite, they can get faster growth, stronger immune systems, and better breeding rates. You are not only just feeding them, but also you are giving them exact nutrition that they need.

Far Less Waste of Feed

Incosistent feed quality is the biggest challeges for any aquaculture farmer. Bad quality feed can cost you weeks of work and lose a lot of money. If you build your own aquafeed processing plant, you no longer have to worry about this.

Each pellet of feed you produce will be a perfect replica of the previous one, with the same texture and nutritional value. This consistency has another huge benefit: it dramatically cuts down on waste.

Low-quality feed often disintegrates too quickly in the water before it can be consumed. This instability results in significant feed waste, which is effectively a direct financial loss.

In contrast, many farm operations report a significant improvement when they switch to a better feed. Using a high-quality, stable pellet can reduce feed waste by more than 20%. This improvement in efficiency translates directly into substantial and accumulating cost savings.

A Smarter Business and a Healthier Planet

While there is an upfront investment, it allows you to produce aquatic feed in large, efficient batches. This significantly lowers your cost per pound over time. Over time, the aquafeed processing plant will get you more profits through these savings.

Modern aqua fish feed production plant is built to be energy-efficient. More importantly, when fish eat and digest their food better, there will be less wasted feed and end up polluting your water. This means healthier ponds and a more sustainable operation all around.

Core Value Proposition

Key Benefits for Aquaculture Operations

| Advantage | Technical Specification | Typical reported impact (verify locally) |

|---|---|---|

| Precision nutrition | Protein retention ≥92% | Supplier/field reports: up to ~20% faster growth (varies by species & formula) |

| Cost efficiency | USD 280–350 / ton (typical) | Reported production cost reductions vs manual methods ~30–40% (estimate; validate locally) |

| Customization | Pellet size 0.5–15 mm | Supports many species and life stages |

Extrusion Control Standards

| Parameter | Range | Monitoring Method |

|---|---|---|

| Temperature | 130-150℃ ±2% | Infrared sensors |

| Pressure | 3-5MPa | Digital manometers |

| Retention Time | 25-40s | PLC timers |

How to Choose the Right Aqua Feed Line

What is the real capacity you need?

When evaluating equipment, it is important to look beyond the standard advertised capacity. It is recommended to request performance data from the supplier based on a specific and complex formulation, such as a high-fat salmon feed.

This is because the production yield for challenging recipes can be substantially lower than for simple, easy-to-process materials like corn.

How efficient is the dryer?

A frequent and costly error in production line design is to mismatch the capacity of sequential equipment, such as the extruder and the dryer.

If the dryer’s capacity cannot match the extruder’s output, it creates a critical bottleneck. The entire production line is then forced to operate at the slower pace of the dryer, which negates the investment in a high-capacity extruder and severely limits overall efficiency.

What about after-sales support and spare parts?

This is the most important question. I always ask suppliers directly: ‘If my extruder’s screw wears out, how quickly can you get a replacement to Anchorage?’ The answer tells me everything I need to know about them as a long-term partner.