| Price | 800-5000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Feed Crusher Machine Specifications: Power, Output & Raw Materials

| Production Output | 0.1-5 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley, soybean, straw, hay, alfalfa, grass, etc |

| Type | hammer mill |

| Final product size | 0.4mm-15mm |

| Application | crushing raw materials into fine powder |

| Used For | fish, animal, and poultry feed |

Feed Grinding Process video

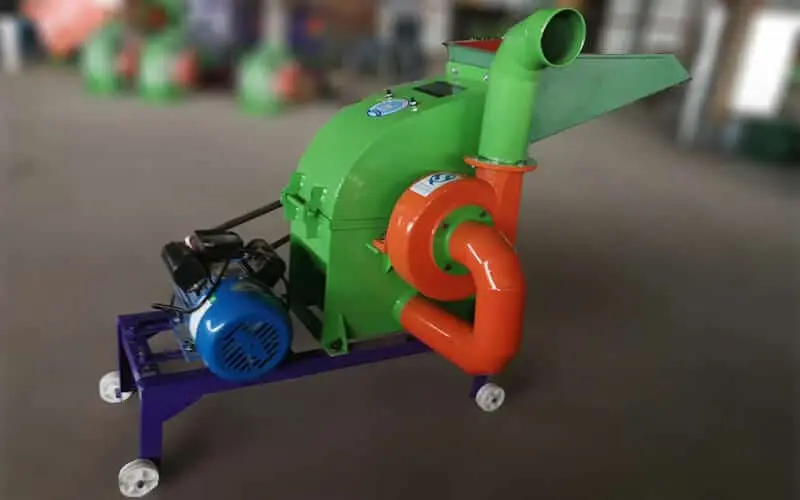

What is a Feed Crusher Machine? Core Functions Explained

what is feed crusher machine?

feed crusher machine is used to break big materials into fine powder for poultry and animal food like crushing fish feed, cattle feed and chicken feed etc. it is easier for poeple to use the machine to make animal food. the crushing machine works through hammering among hammer blades. This breaks materials like corn or wheat into fine powder.

Animal feed factories need machines that crush animal feed. They get things ready to make food pellets. You might know about querns (round grinding stones) and mortars (bowls with a tool for pounding). Compared to the old manual one, the new advanced feed crushing machine can save you time.

Adjustable Particle Size: 0.4mm to 15mm Feed Grinding

The feed crusher machine can be used on pigs, cows, chickens, and other farm animals. It can make power sizes from 0.4 mm to 15 mm.

The powder becomes as smooth as baking flour when the size is less than 1mm. This fine powder is used by farmers to make soybean flour or cornmeal. This powder is safe for people and animals.

Smaller holes make baby animals’ powder finer. Bigger holes make crunchy bits for adult animals. The steel used to make all the parts is safe for food, so the powder stays clean.

Electric vs. Diesel Feed Crusher: Specifications and Models

electric type

| Model | Electric Power(kw) | Output(kg/h) | Weight(kg) |

| VTFQ-320 | 3 | 100-300 | 50 |

| VTFQ-360 | 5.5 | 400-600 | 110 |

| VTFQ-400 | 7.5 | 700-900 | 160 |

| VTFQ-420 | 11 | 900-1200 | 180 |

| VTFQ-500 | 15 | 1200-1500 | 210 |

| VTFQ-600 | 22 | 1500-2000 | 500 |

| VTFQ-700 | 30 | 2000-3000 | 700 |

| VTFQ-800 | 37 | 3000-5000 | 1000 |

| VTFQ-900 | 45 | 5000-7000 | 1700 |

| VTFQ-1000 | 55 | 8000-100000 | 2400 |

diesel engine type

| Model | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTFQ-320 | 4 | 100-300 | 50 |

| VTFQ-360 | 7 | 400-600 | 110 |

| VTFQ-400 | 10 | 700-900 | 160 |

| VTFQ-420 | 15 | 900-1200 | 180 |

| VTFQ-500 | 20 | 1200-1500 | 210 |

| VTFQ-600 | 30 | 1500-2000 | 500 |

| VTFQ-800 | 40-50 | 3000-5000 | 750 |

electric type

diesel engine type

Multi-Purpose Feed Crusher Benefits: Cost-Effective & Versatile

The poultry feed crusher machine is great for small farms, big feed factories, and people who want to use it at home. It doesn’t cost much, but it works very well. The machine can turn corn, wheat, soybeans, and dry plants like straw or leaves into very fine powders.

You can pick between an electric motor and a diesel engine for power. The diesel engine feed crushing machine can help farms that don’t have three-phase power lines.

The feed crushing machine is easy to clean and has a simple design. Its steel blades are strong enough to crush hay and alfalfa. Both the electric and diesel versions cook food for chickens, ducks, and other birds safely.

Food-Safe Grinding Process for Animal Feed Materials

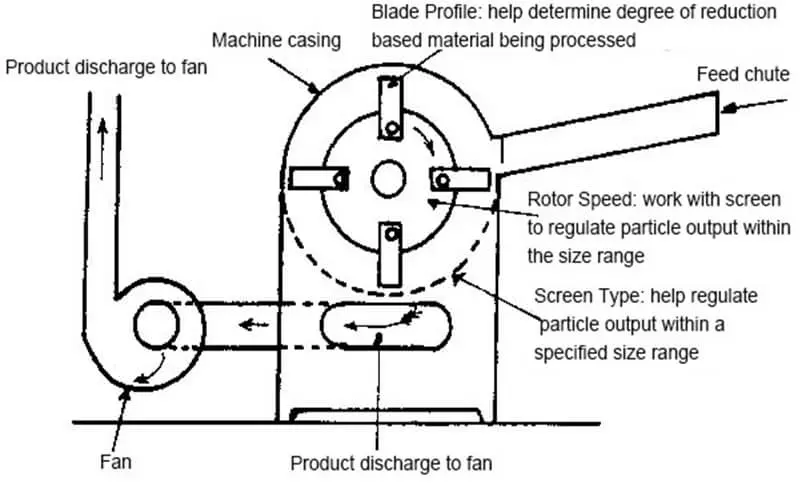

working principle

The feed crusher machine gets the raw materials from the top bin. Metal screens smash them against spinning hammer blades. The machine pushes the crushed bits through the screens using air flow and spinning force.

When the pieces are small enough, they shoot out of the holes in the screen. The powder is carried by air to a spinning separator. The cyclone is like a tornado; it sends the last powder into bags for storage.

The hammer blades keep hitting the raw materials until they turn into powder. The screen has holes of different sizes, which lets you control how big the small fine powder is. All of the parts are made of steel that is safe for food so that the animal food stays safe.

raw materials

This hammer mill can do a lot of things, including crushing poultry feed. It can grind up rice, corn, soybeans, sorghum, and barley. It can also break up hay, straw, grass, alfalfa, and other plants.

Custom Feed Sizing for Poultry, Cattle, and Sheep

Animal-Specific Feed Formulations: Chickens, Pigs, Cattle

Animal feed crushers break down raw materials into the right sizes for animal food. These machines help make special food for different kinds of farm animals:

The machine makes very fine powder for chickens. This makes it easier for birds to digest food and get the most nutrients. This fine powder is used by farmers to make chicken feed.

The machine can give cattle coarser crumbs. Both dairy and beef cattle need these bigger pieces. This size can help them digest better and make more healthy meat and milk.

Pigs need both small and big pieces. Baby pigs need smaller pieces of powder, but grown pigs need bigger pieces. This helps them grow at every stage.

Rabbits and sheep need crumbs with a lot of fiber. The machine can keep plant fibers whole to help with digestion. Storage bags keep all animal foods fresh.

3 Ways Feed Crushers Improve Nutrition & Reduce Waste

poultry feed crusher machine help farmers in three key ways.

First, they make it easier for animals to digest food. When the machine breaks things down into the right size powder, animals can better absorb nutrients. This can help cows, pigs, and chickens get stronger.

Second, the machine can cut down on food waste. It grinds everything up completely, so you can use all of the corn, wheat, or soybeans. You can save money on wasted feed by not throwing anything away.

Third, you can save money by making your own food for your pets and birds. You can make your own recipes, but you have to buy expensive powder feed. You can add corn as an extra food for cattle, but you should add more protein to poultry food.

operation and maintanence

How to Operate a Feed Crusher: Simple Design & Fast Processing

The poultry feed crusher machine is easy to use and works quickly. Its simple and easy design makes it easy for anyone to use. even if you don’t have any special training. Poultry farmers don’t have to clean and fix the machine as often.

The machine can quickly process a lot of materials. You can grind a bucket of corn in just a few minutes, which will save you hours of work. It has a powerful motor that lets it work all day without slowing down.

Different screens change how fine the powder is. Pick holes between 0.4mm and 15mm, just like you would pick the size of a pasta strainer. Small holes in the screen turn things like flour into powder, which is better for baby birds, but bigger holes are better for adult birds and animals. This helps you cook the right food for each stage of growth.

Feed Crusher Maintenance Guide: Cleaning & Part Replacement

When you use your poultry feed crusher machine, always follow the instructions. To keep the machine working well, clean it after each use. Here is how to take good care of your crusher:

Before you start, make sure to check the machine carefully. Check that the rubber belts are tight but not too tight. The crusher works more slowly when the belts are loose. Replace the belts right away if you see cracks in them.

You need to clean both the inside and outside of the machine. Do this job, especially if you don’t use it very often. This can stop it from rusting and keep the holes in the screen clear. You can clean the machine and the screen with a soft brush. You should quickly replace parts that are worn out or broken and check the hammer blades and screens often.

The bearings on the crusher will get hot when it is working. After 2 to 3 hours, it should be normal for it to be up to 25°C (77°F). Turn off the machine and replace the bearings if the temperature reaches 60°C (140°F).