| Price | 4500-50000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Electric Fish Feed Dryer Machine Overview

| Production Output | 0.1-5 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | pellets |

| Type | electric heating |

| Drying Layers | 3-7 layers |

| Application | drying feed pellets |

| Used For | drying animal, poultry, and fish feed |

VTHG Fish Feed Dryer Specifications: 0.1-5T/H Capacity & 3-7 Layer Design

| Model | Output(kg/h) | Heating Power(Kw) | Mesh Power(Kw) | Fan Power(Kw) | Number of Layers | Weight(Kg) |

| VTHG-150 | 100-200 | 18 | 2.2 | 0.24 | 3 | 650 |

| VTHG-250 | 200-300 | 24 | 2.2 | 0.24 | 5 | 850 |

| VTHG-350 | 300-500 | 27 | 2.2 | 0.24 | 5 | 980 |

| VTHG-500 | 500-700 | 30 | 2.2 | 0.67 | 5 | 1500 |

| VTHG-750 | 700-900 | 37 | 3.0 | 0.67 | 5 | 2200 |

| VTHG-1000 | 1000-1500 | 45 | 3.0 | 1.2 | 5 | 3100 |

| VTHG-2000 | 1500-2000 | 55 | 5.5 | 1.5 | 7 | 3800 |

Industrial Fish Feed Drying Process videow

what is fish feed dryer machine?

This floating fish feed dryer machine is used to dry final floating fish feed food, it is usually works with fish feed processing plant. We make two kinds of pellet dryer machines: stainless steel and common steel.

Energy-Saving Drying Solutions: Electric vs Steam Systems

They use heat power from electric or steam. Wet fish food moves on a steel net belt inside. there are many moving mesh layers to dry food fast. The feed pellet dryer machine is very good for drying pet food, chicken feed, and fish feed.

Multi-Layer Convection Drying Mechanism

fodder is usually hot and wet after extrusion. Hot air blows while food moves through the fish feed drying machine. Workers can set heat, damp, and air flow just right with easy bottons.

Keeping Your Dryer Clean

you need clean the mesh each day to prevent bits from sticking. Farmers can save money through this fish feed pellet dryer machine with less spoiled feed.

this pellet dryer machine works safe and smooth. Its closed box stops dust from getting out. A motor part moves the wet food on a net belt inside. Hot air blows up through the mesh to dry the fodder.

common steel fish feed dryer machine

stainless steel fish feed dryer machine

Keeping Your Feed Pellet Dryer Clean

Heat moves well all through the food. It dries the fodder superly fast and even. you can save money and time with the advanced fodder drying machine. Press buttons to set heat and air flow just right. Clean the belt each day to keep the feed pellet dryer machine working like new.

working principle of floating fish feed dryer machine

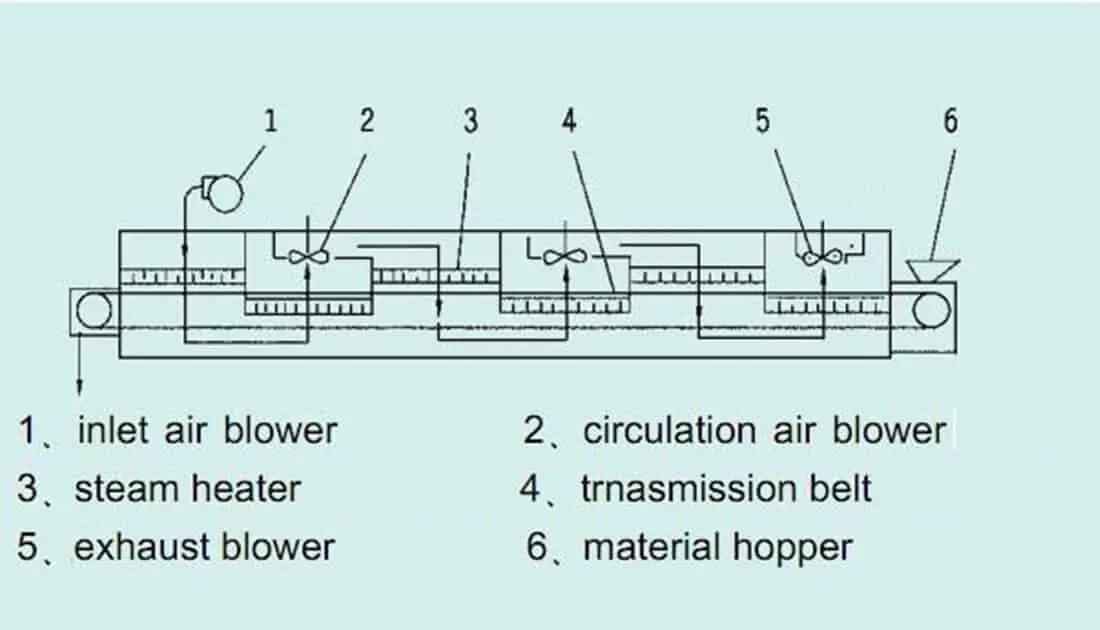

Key Components of Fish Feed Dryer

This feed pellet dryer machine has four main parts: wind maker, heat box, air in hole, and air out hole in a closed box. Wet fish food bits on a net belt get dry when hot air blows down or up. It reuses some air and lets out the old.

Hot Air Circulation System

Heat works well through all the food bits. Turn knobs to pick hot air direction. Clean the belt each day to stop bits from burning. Farmers get more feed with less waste. there is a lot of parts in the pellet dryer machine.

Mechanical Structure Breakdown

Each part has a wind blower, heating box, and air pipes. A strong metal belt moves fish food. It runs with a motor and gear team. You can set the heat smartly. Hot air moves just right.

Heat Path & Smart Controls

Hot air dry the fish food bits as they move on the mesh through special paths. This feed pellet dryer machine has different parts that work on their own. Each part has a wind maker, heat box, and air pipes for clean air in and old air out. You can easily set how hot the air gets and how much flows through. The smart controls keep everything working just right. Wipe the belt clean after use to keep it working like new.

Daily Cleaning & Safety Guide

you should clean the mesh each day for keeping fish food safe. with this pellet dryer machine, farmers can use less power and get dry food fast. Press buttons to change air flow. No dust comes out of the closed box.

This floating fish feed dryer machine has four main parts: wind blowers, heating boxes, air in pipes, and air out pipes. Workers can set the heat, damp, and air flow. This keeps the dryer working well and safe.

The net belt design is both safe and easy to use. Hot air moves through the net to dry food bits fast. Press buttons to change settings when making different animal foods.

12 Engineering Advantages of VTHG Fish Feed Pellet Dryer

1. The material will not vibrate or impact during the drying process, and the particles remain intact.

2. You can adjust the air volume, heating temperature, material residence time, and feeding speed to achieve the best drying effect.

3. The floating fish feed dryer has a simple structure and is easy to install and maintain.

4. This pellet dryer machine mostly meets requirements for slow drying speed and long drying time.

5. Ideal for drying pellets, grains, etc. The tumble drying process prevents its use for drying viscous and fragile materials.

6. The configuration of floating fish feed drying machine is very flexible. Simple structure, easy installation and maintenance.

7. The material is not subject to vibration or shock during drying, so the particles will remain intact.

8. You can adjust the air volume, heating temperature, material residence time, and feeding speed to achieve the best drying effect.

9. Hot air can be recycled, which greatly saves energy.

10. The unique air distribution device makes the hot air evenly distributed; this can ensure the quality of the product.

11. This pellet dryer machine is ideal for drying pellets, grains, etc.

12. Commonly used in occasions with low drying speed and long drying time.

Core Components: Mesh Belt & Heat Circulation Systems

the head of the fish feed dryer

The dryer’s front part has two spinning drums, a tightener, and holes for putting in and taking out food. How tight the net belt sits depends on the free-spinning parts.

Workers should oil both ends of these parts with special hot grease (over 200℃) to keep things working smooth. Use the tightener knob to adjust the net belt’s stretch. When setting up for the first time, tighten the net belt.

After heating, tighten it a bit more. Always wear thick gloves when touching hot parts. This keeps the pellet dryer machine running safe and stops the belt from slipping.

the end of the fish feed pellet dryer

The motor part goes at the back of the pellet dryer machine. Moving the gear box changes how tight the chain sits. Put oil on the gears behind the gear box to keep them working longer.

Use the red knob to adjust the chain’s stretch. Always wear work gloves when touching metal parts. Check the chain each week to stop wear. This keeps your dryer running smooth for years.

Hot grease works best for the gears near heat spots. Turn off power before any fixes.

the section of the fish feed dryer

This is where the real drying happens. Hot air pipes and exit pipes sit on top. Warm air blows in from both sides at the bottom. Big fans pull the air out through the middle.

Workers use knobs to control how fast air moves in and out. Always check the pipe connections before starting the fish feed drying machine. Keep the air holes clean for best drying. Turn the blue knob to adjust heat levels.

Wear heat gloves when touching metal parts. This setup dries fish food fast and saves energy.