| Price | 3500-5500 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

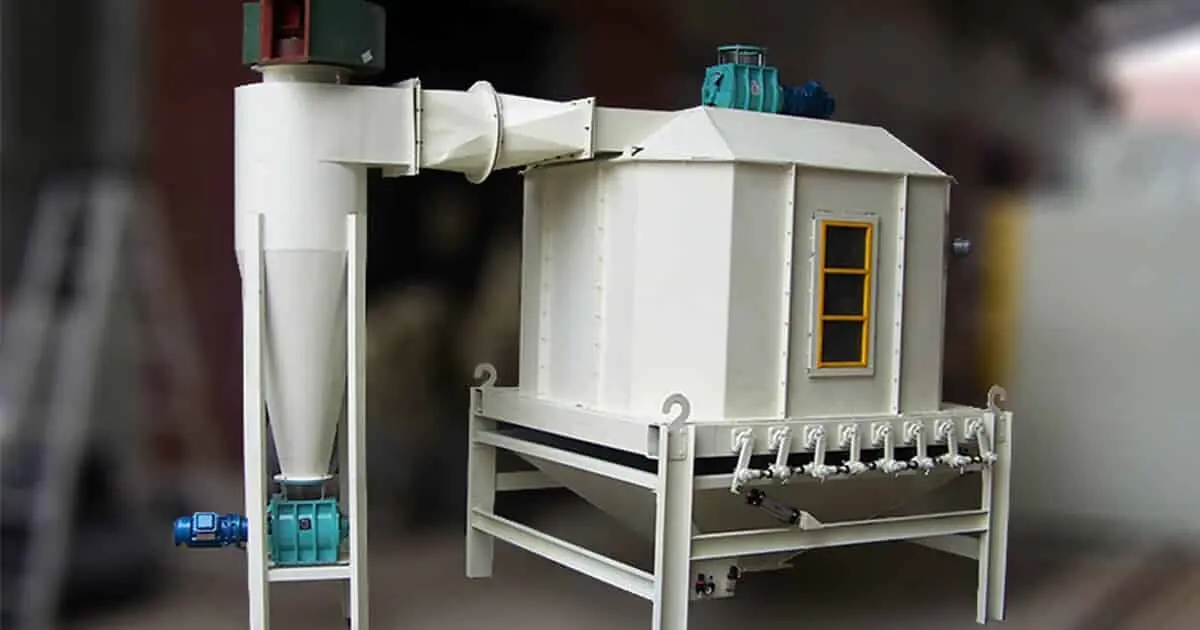

SKLN Series Counterflow Pellet Cooler: 0.1-5T/H Capacity & ±3℃ Precision

| Production Output | 0.1-5 t/h |

| Power | Electric motor |

| Precision | ±3℃ |

| Voltage | 110-415V |

| Raw Materials | pellets |

| Type | counterflow cooler |

| Dust Collection | cyclone |

| Application | cooling pellet feed |

| Used For | animal, poultry, fish feed |

Technical Parameters: Industrial Feed Cooling Systems

| Model | Capacity (t/h) | Feed motor power | Discharge motor power (kw) | Shaker motor power (kw) | Fan model | Cyclone model | Size L*W*H (mm) | Weight (kg) |

|---|---|---|---|---|---|---|---|---|

| SKLN11 | 1-2 | 0.75 | 0.75(slide)0.2*2(vibration) | 0.2 | 4-72-4A/5.5Kw | 800 | 2150*1325*3050(slide)2150*1325*3450(vibration) | 800 |

| SKLN14 | 2-5 | 0.75 | 1.5(slide) 0.2*2(vibration) | 0.4 | 4-72-4.5A/7.5Kw | 1200 | 2500*1650*3200(slide)2500*1650*3600(vibration) | 1200 |

| SKLN16 | 4-7 | 0.75 | 1.5(slide) 0.2*2(vibration) | 4-72-5A/11Kw | 1500 | 2100*2000*3130(slide)2100*2000*3600(vibration) | 1500 | |

| SKLN19 | 5-10 | 1.1 | 1.5(slide) 0.2*2(vibration) | 4-72-6C/18.5Kw | 2000 | 2450*2370*3480(slide)2450*2370*3000(vibration) | 2000 | |

| SKLN21 | 8-15 | 1.1 | 1.5(slide) | 4-72-8C/22Kw | 2500 | 2800*2300*4600(slide) | 2500 | |

| SKLN24 | 8-15 | 1.1 | 1.5(slide) | 4-72-8C/30Kw | 3000 | 3100*2600*4600(slide) | 3000 |

what is pellet cooler machine?

The feed pellet cooler, a counterflow cooling machine in feed plants, matures materials and boosts pellet quality and water resistance. The animal feed cooling machine has the characteristics of high degree of automation and advanced technology.

It is an ideal pellet cooling system for industrial production of special aquatic feed and high-grade livestock feed. The machine has two functions: lowering the granules temperature and lowering particle moisture.

Pellets exit the feed machine at 70℃~90℃ and cool to 3℃~5℃ below room temperature in the poultry feed cooling machine. Moisture drops to under 12.5%, aiding storage and transport. As manufacturers, we offer our cooling system at a low price.

Counterflow pellet cooling machine is a new type of system popular in the international market. It uses the principle of counterflow cooling to cool high-temperature, high-moisture granular particles.

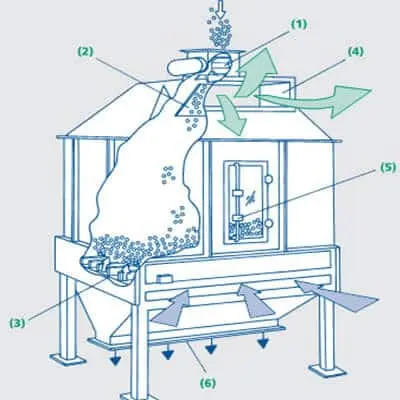

Cold air moves vertically through the material, first chilling, then heating as it contacts hotter material, opposite to the material flow. The particles gradually cooled and moved in a straight line. Avoid particle surface cracking by preventing direct cold air and hot particle contact, unlike other coolers.

Cold air fully enters from the bottom, using a large intake area and high cold air utilization. This results in superior cooling, low energy use, and easy operation, making the counterflow pellet cooler an upgrade over vertical and horizontal coolers.

Advanced Feed Cooling Technology: Counterflow Mechanism

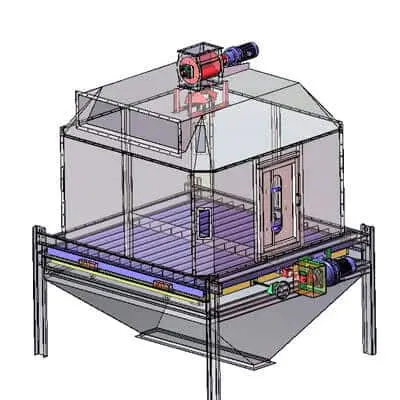

The hot granules from the feed pellet machine enter the unit bin through the inlet rotary valve. Below the inlet rotary valve, the distributor evenly distributes the particles in the cooler.

Air flow cools particles in the silo, entering through the discharge door and exiting via the air outlet. A liquid level sensor controls the particle layer height. Level sensors ensure that the product layer remains at a predetermined height.

When particles activate the level sensor, the pendulum discharger operates and discharges the particles through the hopper. Once the product falls below the level sensor, the unloading stops.

To prevent overflow, the cooler has an overflow sensor that halts product supply to the feed cooling system.

6 Engineering Advantages of SKLN Cooling Systems

- Utilizing counter-flow, the pellet cooler machine efficiently cools high-temp, high-humidity materials, thus preventing the formation of cracks by avoiding direct cold air contact with hot pellets. An octagonal design ensures the refrigeration water tank has no dead angles for more effective cooling.

- Featuring an air-tight feeder, this system benefits from a large air inlet area and excellent refrigeration effect.

- With its sliding valve reciprocating type, the discharge device operates stably and reliably with minimal residue.

- Pellets are cooled to ambient temperature +3~5℃, affirming the system’s appropriateness for feed refrigeration.

- The pellet cooling machine boasts a fast chilling speed and effective chilling, chilling more pellets while preserving optimal food quality.

- Highlighting low power consumption, this machine is also noted for its convenient operation and cleaning, coupled with high production efficiency.

Critical Quality Control: Crack Prevention & Moisture Management

1.Cooling can directly affect the quality of final feed pellets, so it should be a gradual process. Quick chilling of pellets can cause outer layer cracks, leading to higher abrasion. Moreover, with short chilling period, the inner part of pellets is still warm and pellets are still moist and sticky. And cooling very slowly will make pellets become too dry, which also results in cracks.

2.It should be noticed that small pellets emit heat and moisture more quickly than large pellets. Even distribution of pellets in the pellet cooler machine also enhances the cooling process.

3.Generally speaking, air speed in counter flow pellet cooling machine should stay between 0.8 and 1.5 m/s