| Price | 500-3000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Feed Pellet Machine Specifications: Power, Output & Materials

| Production Output | 0.1-2 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | rice, corn, wheat, barley, soybean, oil seed, leaf, fish meal, straw etc |

| Type | flat die |

| Final product size | 2-12 mm |

| Application | feed pellet |

| Used For | animal feed production |

Electric vs. Diesel Feed Pellet Machines: Model Comparison

electric feed pellet mill

| Model | Electric Power(kw) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 3 | 50-80 | 80 |

| VTKLP-150 | 4 | 100-150 | 110 |

| VTKLP-210 | 7.5 | 200-400 | 210 |

| VTKLP-230 | 11 | 300-500 | 280 |

| VTKLP-260 | 15 | 500-700 | 300 |

| VTKLP-300 | 18.5 | 700-900 | 500 |

| VTKLP-360 | 22 | 900-1200 | 700 |

| VTKLP-400 | 30-37 | 1200-1500 | 900 |

diesel engine feed pellet mill

| Model | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 4 | 50-80 | 100 |

| VTKLP-150 | 5 | 100-150 | 150 |

| VTKLP-210 | 10 | 200-400 | 260 |

| VTKLP-230 | 15 | 300-500 | 350 |

| VTKLP-260 | 20 | 500-700 | 420 |

| VTKLP-300 | 25 | 700-900 | 650 |

| VTKLP-360 | 30 | 900-1200 | 900 |

| VTKLP-400 | 40-50 | 1200-1500 | 1200 |

animal feed production video

What is a Feed Pellet Machine? Functions & Nutritional Benefits

The main goal is to give animal farmers and homesteaders the tools they need to make their own feed, which gives them complete control over the proteins and nutrition of their animals. You can make special pellets for a lot of different kinds of livestock with this flexible system.

For example, you can produce high-quality cattle feed, create balanced rations with a dedicated pig feed pellet machine, or make high-fiber pellets with a specialized rabbit feed pellet mill. The machine can process different materials like corn, soybean, wheat, fish meal, grass, rice bran and other essential vitamin and mineral premixes.

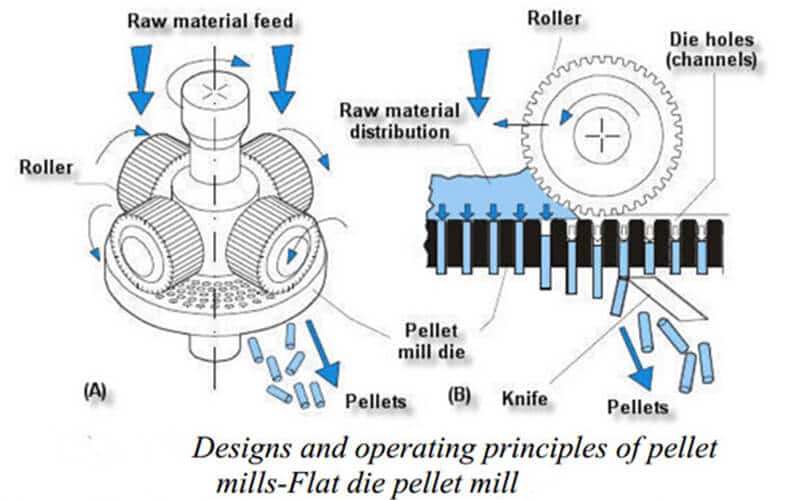

How Does It Work? The Core Function

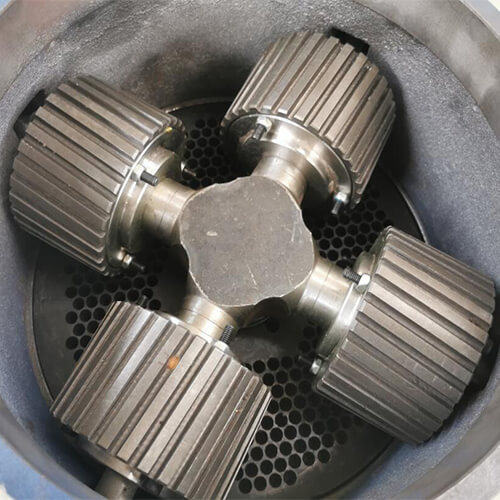

The animal feed pellet machine works by putting a lot of pressure and heat on the roller and die. The first step is to put the mixed raw materials into the machine’s chamber. The rollers assembly in this chamber presses the material against the die with a lot of force.

This very high pressure squeezes the loose powder ingredients into solid, dense pellets. During the process, the rollers and die rub against each other, which creates a lot of heat and pressure. This makes the pellets safe for animals and of high quality.

The Key Nutritional Benefits of Pelletized Feed

Making feed by this process offers several important nutritional benefits. First, the pelleting temperature during process can reach to 70-85°C, it can pasteurize the feed. This process helps to kill harmful bacteria like Salmonella that might be in the raw ingredients. This will make the food safer for your animals.

Second, this heat and pressure can make it easier for the body to break down starches in grains. It makes it easier for the animal’s digestive system to get to the energy in the food.

Finally, because each pellet has all the nutrients it needs, it stops a common problem called selective feeding. This makes sure that animals eat everything and get all the nutrients they need, not just their favorite food.

Feed Pellet Technology Advancements: Mold Customization & Force Control

Using cutting-edge technology, our engineers improved this animal feed pellet machine. The parts of the gear system are tough enough to handle trucks and move power without slipping. Workers can quickly switch out molds to make food bites for sheep, pigs, cows, and other farm animals that are 2mm to 10mm long.

This powerful animal feed machine works all day with a lot of force. Eight special molds make it easy for farmers to change the size of their pellets. Smart heat control makes sure that every pellet is the same hardness, which is great for baby chicks and grown cows.

electric feed pellet mill

diesel engine feed pellet mill

Scalable Feed Production: 50lb/h to 1200lb/h Capacity Options

There are different models of this animal feed maker machine for each farm. The small models can make 50 to 200 pounds of food an hour, which is great for chickens in the backyard or at home. Big models can make up to 1200 pounds of food per hour, which is enough for big farms.

You can pick between tough diesel engines that work anywhere and plug-in electric power. The animal feed pellet machine grows with your farm, like a mini food factory.

You can start with models that weigh between 50 and 80 pounds. When your flock grows, you can move up to models that weigh more than 1,000 pounds. All versions come with farm-tested gears that keep working year after year.

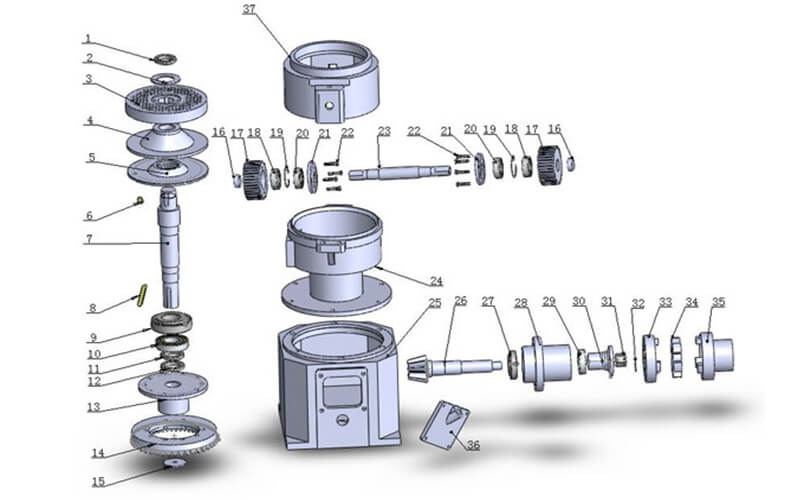

Key Components: Flat Die, Rollers & Cutting System

There are important parts of the animal feed pellet machine that work together. The parts that make up this machine are the power box, the feeding bin, the discharging bin, the rollers, and the die. The electric motor makes the machine work harder but slower. You can change the size of the hole in the die to fit different needs.

Flat Die

The flat die is what shapes the pellets. It is attached to the animal feed machine and has a lot of little holes. The pellets get bigger and stronger depending on the thickness of the die and the size of the holes.

It also decides how much can be made, like how 5mm size can only be 200kg/h. Hard metals make it work for a long time. The die can last for about 800 hours.

Pressing Rollers

These round rollers go with the flat die. Two to three rollers are used in most animal feed pellet machines. They spin around the center of the die and push prepared materials through its holes.

Cutting Tools

The blade cut the pellets into the right length. People can change the blades to make the pellets longer or shorter as needed.

Power System

This gives energy to the whole machine:

- Electric motor creates movement

- Gearbox makes power stronger

- Rubber belts send power to parts

Oil System

You need to add oil to lubricate parts like bearings to keep parts moving smoothly. This will help the animal feed pellet machine last longer.

Control Panel

It’s like the brain of the machine. Workers can change settings by using buttons or touchscreens. The machine’s operation is shown by clear screens.

65-70℃ Precision Heating for Safe Feed Pellets

A hopper lets materials into the animal feed pellet mill. Heavy rollers push them against the flat die with holes on the inside. This pressing takes place at very high temperatures, between 65 and 70 degrees.

The heat makes animal food pellets safer and better. The machine has an electricity control box, and you can use the simple buttons to run it. This makes the machine work at its best. You can easily control how the pellets are made with it.

Animal Feed Pellet Machine Price for Home and Commercial

The price of an animal feed pellet machine depends on its size and capacity. Most small machines for home use cost between $500 and $2,000. They are better for small farms or homes. These are great for making food pellets for chickens and other animals.

A larger feed pellet mill could cost more than $10,000. They are better for farming on a large scale or for business. Such heavy-duty machines are often needed by big farms and feed factories. The price of the feed making machine depends on how big it is and how much it can make.

The smallest feed pellet mill is cheap; it can cost as little as a few hundred dollars. Before making a choice, you should always check how much animal food you need to make.

4 Cost Factors: Size, Controls, Durability & Brand

There are four main reasons why the cost of an animal feed pellet machine varies. Machines that make more pellets and are bigger cost more. Small machines are good for family farms that feed chickens.

Big machines are better for big factories. At first, machines with smart computer controls cost more. But they save money later because they don’t use as much electricity. Some have simple screens that help make perfect pellets.

The animal feed pellet mill is made with strong steel, it can work for long time. They cost more and break less.

Brands that are well-known and have good repair support cost more. The supplier who has been making feed pellet mills for more than 10 years usually helps fix problems faster.

Considerations When Buying Animal Feed Pellet Machine

You should know how much food you need each day before you buy an animal feed pellet machine. Then pick the right tools and don’t pay more than you have to. Also, think about how much power it uses and how often it needs to be fixed.

Look for a supplier who sells high-quality machines and can help you fix them when they break. Different animals, like chickens, cows, and rabbits, need pellets of different sizes. You should check to see if the machine can make pellets of different sizes.

You should check to see if the spare parts are easy to find before you buy the animal feed machine. The supplier may need to help with big machines in a special way. When you need spare parts quickly, good suppliers can send them right away.

Intelligent Equipment Selection System

| Farming Scenario | Recommended Model | Daily Output (kg) | Daily Energy Cost | ROI Period | Upgrade Path |

|---|---|---|---|---|---|

| Household Farming | |||||

| 500 Laying Hens | VTKLP-125 | 80-120 | $ 2.4 | 8 Months | → VTKLP-210 |

| 20 Pigs | VTKLP-150 | 150-200 | $ 3.6 | 10 Months | → VTKLP-230 |

| Medium Farm | |||||

| 1,000 Broilers | VTKLP-210 | 300-400 | $ 7.2 | 14 Months | → Dual VTKLP-260 |

| 50 Dairy Cows | VTKLP-260 | 700-900 | $ 16.8 | 18 Months | → VTKLP-400 + Automation |

| Enterprise Level | |||||

| 100,000 Poultry | VTKLP-400 ×3 | 3,600 | $ 86.4 | 24 Months | Custom Production Line |

High-Protein Raw Materials for Nutrient-Rich Pellets

Corn, wheat, rice, and soybeans are all grains that are high in protein (10–14%). They are the best for growing animals. These grains also have a lot of B vitamins, such as B1, B2, and B6. These vitamins can help animals break down food more easily.

Rapeseed and cotton plants make protein-rich feed for animals. About 38% of them is protein. They are great for helping animals gain muscle. But these also have 12% rough fiber and unique plant compounds from the mustard family.

Some animals may need more help when they eat. Straw and rice bran are examples of grassy foods that can help animals stay healthier.