| Production Output | 0.1-2 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal, kinds of powder, etc |

| Type | flat die type |

| Final pellet size | 2-10 mm |

| Used For | poultry feed, chicken feed, duck feed, bird feed, goose feed, |

Introduction: Precision Nutrition for All Poultry

Optimizing flock performance starts with precision nutrition. Our poultry feed pellet mill series is engineered to convert loose mash into hygienic, high-density pellets, serving as the central solution for modern poultry farming.

Whether targeting rapid weight gain in broilers or eggshell quality in layers, utilizing specialized pelleting equipment eliminates selective eating and ensures uniform nutrient absorption. Industry data indicates that switching to pellets can improve the Feed Conversion Ratio (FCR) by approximately 10-12% while significantly reducing feed wastage.

We offer scalable solutions to match any operation size: from compact, single-phase units for start-ups to industrial ring-die systems integrated with steam conditioning for pathogen control.

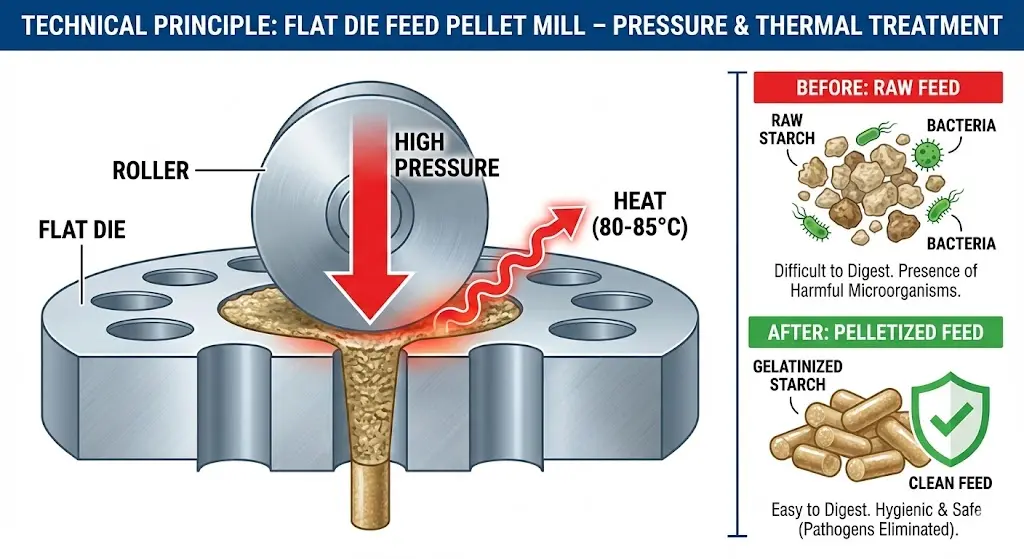

Sanitization & Gelatinization: The Technology Difference

Distinct from ruminants like cattle feed pellet mill and goat feed pellet mill, poultry are monogastric animals that require highly digestible, pathogen-free nutrition. Our technology addresses this biological need through two critical thermodynamic processes:

Starch Gelatinization (Digestibility): Raw grains like corn contain resistant starches. The high pressure within the pelleting chamber generates internal temperatures between 80°C and 85°C. This induces starch gelatinization, improving feed digestibility by over 15%.

Pathogen Neutralization (Biosecurity): Bio-security is paramount. The pelleting process functions as a critical “kill-step,” effectively neutralizing harmful pathogens including Salmonella and E. coli. This guarantees consistent feed hygiene and a healthier flock.

5-Step Poultry Feed Production Process: From Grains to Quality Pellets

To ensure nutrient uniformity, a professional poultry feed production line machine follows a precise workflow:

- Grinding:

Unlike ruminant feed, poultry requires fine grinding. A hammer mill pulverizes corn and meal to a mesh size of 2.0mm – 3.0mm for rapid digestion.

- Mixing:

A twin-shaft mixer blends vitamins and minerals, achieving a Mixing Uniformity (CV) of ≤ 5%.

- Pelleting:

The conditioned mash is compressed into dense pellets using either flat die or ring die technology.

- Cooling:

Fresh pellets are cooled to ambient temperature for safe storage.

- Crumbling (Specialized for Chicks):

Young chicks cannot swallow large pellets. A feed crumbler breaks cooled pellets into smaller granules, a defining step in the poultry feed production process.

Pelletizing video: 5mm poultry Feed

Flat Die vs. Ring Die: Which Poultry feed Pellet Mill Fits You?

Selecting the optimal technology is dictated by your operational scale.

Flat Die Series (Small & Home Farms):

- Best For: Backyard farms (< 2,000 birds) and budget-conscious starters.

- Advantage: Features a vertical feeding design suitable for limited spaces. It offers a cost-effective entry point with lower maintenance requirements. It is compatible with single-phase power, small pellet mill serves as an ideal solution for farmers prioritizing low initial investment.

Ring Die Series (Commercial Production):

- Best For: Farm-scale operations (1–10 tons/hour) and commercial feed factories.

- Advantage: Integrates an advanced steam conditioner to maximize gelatinization, ensuring the premium pellet quality required for commercial broilers.

Tailored Feed Solutions for Every Species

While the core principle remains consistent, different species demand specific feed characteristics. We have specialized feed solutions for each:

- Broilers & Layers: Broilers require high-energy density for rapid weight gain, while Layers need calcium-rich formulas for eggshell strength. Our equipment ensures precise mixing uniformity to support these distinct profiles. Explore Chicken Feed Solutions.

- Waterfowl (Ducks & Geese): Requires higher compression for superior water stability, preventing waste in ponds.

- Small Birds (Quail/Pigeon): Utilizes high-precision dies capable of producing micro-pellets (1.5mm – 2.5mm).

Poultry Feed Mill Specifications & Capacity Matrix

Proper equipment sizing is fundamental to operational efficiency. We recommend selecting a model based on the total daily feed consumption of your flock. The matrix below outlines our core poultry feed pelletizer machine series, correlating technical poultry feed pellet making machine capacity (kg/h) with practical application scenarios.

| Model Series | Technology | Capacity (Output) | Power & Voltage | Ideal Application |

| VTKLP-150 | Flat Die | 100 – 150 kg/h | 4 kW (1-Phase/3-Phase) | Backyard / Pilot Trial |

| VTKLP-260 | Flat Die | 500 – 700 kg/h | 15 kW (3-Phase) | Small to Medium Coop |

| HMK-300 | Ring Die | 1.0 – 2 Ton/h | 30 kW (Industrial) | Commercial Farm |

| P-Line 5T | Ring Die Line | 5.0 – 10.0 Ton/h | Custom Config | Feed Factory |

Power Type: Electric vs. Diesel

Choosing the right power source depends on your infrastructure. We offer two primary configurations:

| Feature | Electric Motor Type | Diesel Engine Type |

| Best For | Indoor workshops, stationary use | Remote farms, outdoor fields |

| Power Supply | 1-Phase (Home) or 3-Phase (Industrial) | No electricity required |

| Advantages | Low noise, zero emissions, lower running cost | High mobility, powerful torque |

| Model | VTKLP Series (E) | VTKLP Series (D) |

Electric vs Diesel Poultry Feed Pellet Machine Specifications

electric Feed Pellet Mill

| Model | Electric Power(kw) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 3 | 50-80 | 80 |

| VTKLP-150 | 4 | 100-150 | 110 |

| VTKLP-210 | 7.5 | 200-400 | 210 |

| VTKLP-230 | 11 | 300-500 | 280 |

| VTKLP-260 | 15 | 500-700 | 300 |

| VTKLP-300 | 18.5 | 700-900 | 500 |

| VTKLP-360 | 22 | 900-1500 | 700 |

| VTKLP-400 | 30-37 | 1500-2000 | 900 |

diesel engine Feed pellet Mill

| Model | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 4 | 50-80 | 100 |

| VTKLP-150 | 5 | 100-150 | 150 |

| VTKLP-210 | 10 | 200-400 | 260 |

| VTKLP-230 | 15 | 300-500 | 350 |

| VTKLP-260 | 20 | 500-700 | 420 |

| VTKLP-300 | 25 | 700-900 | 650 |

| VTKLP-360 | 30 | 900-1200 | 900 |

| VTKLP-400 | 40-50 | 1200-1500 | 1200 |

electric motor type

diesel engine type

Optimal Raw Materials for Poultry Pellets

Achieving superior pellet durability requires more than just machinery; it demands a scientifically balanced formulation. Unlike ruminant diets based on fibrous roughage, poultry feed pellets must be high in starch to facilitate binding during compression.

- Energy Sources: Grains like corn (maize) and wheat provide essential starch. Under the heat of the poultry feed pellet mill, this acts as a natural adhesive, ensuring pellets hold their shape without crumbling.

- Protein Sources: Soybean meal and fish meal are essential for muscle growth in broilers.

- Additives: Micro-ingredients like Limestone are critical for layer hens to ensure eggshell strength. Our equipment ensures these are uniformly distributed throughout the batch.

How to Choose the Right Poultry Feed Pellet Machine?

Selecting the optimal poultry feed pelletizer equipment requires balancing initial capital expenditure (CAPEX) against long-term operational goals. We recommend evaluating three critical 3 parameters before purchase:

- ROI Calculation: While an investment, producing your own feed typically saves $20-$40 per ton, offering a break-even point within 6-9 months.

- Infrastructure Check: Verify your voltage. High-capacity electric models (VTKLP-230 and above) require 3-phase power.

- Technology Fit: Choose Flat Die for budget/home use, or Ring Die for commercial FCR performance.

FAQ About Poultry Feed Pellet Mill

A: No. Poultry feed pellet machines make sinking pellets. For floating feed, you require a specialized extruder.

A: Chicks need fine granules (1.5mm–2.5mm). We recommend using a feed crumbler to break standard pellets into crumbs.

A: Prices depend on capacity. A small poultry feed pellet machine is the most budget-friendly option. Contact us for a price list.

A: On a standard flat-die poultry feed pellet mill, wear parts typically last 500 – 800 hours. Proper maintenance is key.