| Price | 500-6000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

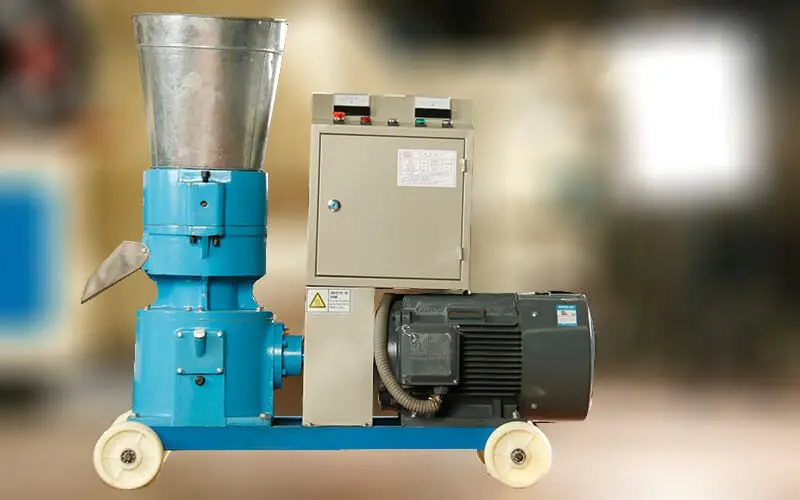

Chicken Feed Pellet Machine Overview

| Production Output | 0.1-2 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal/cake, edible leaf, fish meal, bone powder, etc |

| Type | flat die type |

| Final product size | 3-10 mm |

| Application | food pellet production, feed pellet industry |

| Used For | chicken food production |

Electric vs Diesel Chicken Feed Pellet machine Output & Energy

diesel engine chicken feed pellet machine

| Model | Diesel Engine Power(HP) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 4 | 50-80 | 100 |

| VTKLP-150 | 5 | 100-150 | 150 |

| VTKLP-210 | 10 | 200-400 | 260 |

| VTKLP-230 | 15 | 300-500 | 350 |

| VTKLP-260 | 20 | 500-700 | 420 |

| VTKLP-300 | 25 | 700-900 | 650 |

| VTKLP-360 | 30 | 900-1200 | 900 |

| VTKLP-400 | 40-50 | 1200-1500 | 1200 |

electric chicken feed pellet machine

| Model | Electric Power(kw) | Output(kg/h) | Weight(kg) |

| VTKLP-125 | 3 | 50-80 | 80 |

| VTKLP-150 | 4 | 100-150 | 110 |

| VTKLP-210 | 7.5 | 200-400 | 210 |

| VTKLP-230 | 11 | 300-500 | 280 |

| VTKLP-260 | 15 | 500-700 | 300 |

| VTKLP-300 | 18.5 | 700-900 | 500 |

| VTKLP-360 | 22 | 900-1200 | 700 |

| VTKLP-400 | 30-37 | 1200-1500 | 900 |

chicken Feed Production video: 3-4mm Pellet

chicken feed pellet machine introduction

Chickens naturally choose what they eat when they have loose mash. They will eat the bigger, more desirable grain pieces and leave the smaller, powdery parts of the feed behind.

When chickens spread the fine, dusty powder on the ground, it wastes feed and money. The best way to solve this common problem is to use a chicken feed pellet machine. It takes your whole, balanced feed mix and turns it into a solid, even pellet.

This one change stops the picky eating. This makes sure that every bird gets the full nutrition it needs in every bite. This means less feed waste and a healthier, more profitable flock.

Why Pellets are Better Than Mash: The Real Benefits for Your Flock

There are many strong reasons to switch from mash to pellets that can help your flock’s health and your farm’s bottom line.

Drastically Reduces Feed Waste and Stops Picky Eating

This is the best and most important benefit right away. Each pellet has all the nutrients your body needs. This means that your chickens can’t just pick and choose the things they like.

They eat the whole meal in every bite. This can cut down on the amount of feed that ends up on the floor of the coop by a lot.

Ensures Every Bird Gets a Balanced Diet

Pellets stop selective feeding. This makes sure that each bird in your flock gets the same healthy food. This is important because it makes the flock more even and healthy. The birds that aren’t as strong won’t be left with only the less nutritious parts of the feed.

Improves Feed Digestibility

The process of making chicken feed pellets involves intense pressure and heat. This process causes the starches in the grains to gelatinize. This means the starches are partially cooked.

This makes it much easier for your chickens to digest and absorb the carbohydrates in the feed. This process can make the food they eat more nutritious.

Better Feed Hygiene and Less Dust in the Coop

The heat involved in the pelleting process can also help to kill some harmful bacteria that might be in the raw chicken feed ingredients. This leads to a safer, more hygienic feed.

Also, pellets are much easier to work with and make a lot less dust in the chicken house than dry, powdery mash. This is better for the health of your birds’ lungs and yours as well.

How a Chicken Feed Pellet Machine Works

First, you need to use chicken feed grinder to grind materials into mash powder, then the chicken feed making machine meters the mash onto the die. The rollers then compress and extrude the material through the die holes. A cutting mechanism then trims the pellets to length before they are finally cooled and screened.

The process makes the heat it needs by either using steam pre-conditioning or mechanical friction. For a full explanation of how to pellet, see Pelleting 101, Keep this part short so you can focus on poultry-specific practice.

Machine Scale for Poultry: Flat-Die vs Ring-Die

When to choose a Flat-Die (on-farm/batch use)

- Best for on-farm or pilot runs, typical single-line throughput ≤ ~0.6 t/h.

- Fast die swaps suit frequent poultry size changes: 2.5–3.0 mm (starters) and 4–5 mm (growers/layers).

- Simple drivetrain, fewer service points; practical for single-operator, intermittent production.

- What to check: stable feeding (VFD/force-feed), die material & hardness (e.g., Cr-Mo-V, HRC 58–62), and whether cooler/screener capacity keeps up.

When to choose a Ring-Die (continuous/commercial use)

- Built for continuous duty and higher throughput (commonly ≥ ~0.8 t/h/line), with tighter control of die compression ratio.

- At like-for-like formulas, typically achieves higher durability and lower fines at scale.

- The system is designed for seamless integration with other key technologies. This includes steam conditioning, automated lubrication, and inline quality control sensors to support longer, more stable production runs.

- What to check: conditioner residence-time control (e.g., 20–40 s for poultry), drive & bearing cooling/lube, and spare die/roller changeover time.

What to prioritise for poultry lines

- Die changeover speed & inventory: keep 2.5–3.0 mm and 4–5 mm sets ready.

- Cooler & screener matching: design for PDI ≥95% and fines ≤2–3% after cooling/screening.

- Upstream prep: grind so max particle ≤ 1/3 of die hole; inlet moisture 15–17%; post-cool ≤12–13%.

- Hygiene & dust: enclose transfer points; add a small bag filter at the cooler discharge.

Minimum Technical Specifications for Quality Chicken Pellets

To produce a high-quality chicken feed pellet, your equipment and process must meet several key technical benchmarks.

Moisture and Quality Control Targets

The feed mash that goes into the chicken feed pellet mill should have a moisture content of 15% to 17%. The final pellet must have a moisture content of 13% or less after it has cooled down. The final product should also have a Pellet Durability Index (PDI) of 95% or higher, and the amount of fine particles should be 3% or less.

Equipment Specifications

You need to give the chicken feed pellet making machine die sets for the pellet sizes you need. For starter feed, these are usually between 2.5 and 3.0 mm, and for adult birds, they are between 4 and 5 mm.

Make sure the company that makes the chicken feed machine makes the die out of a strong chrome-vanadium alloy steel with a hardness rating of HRC 58–62 for the longest life. There should also be a feeder with speed control and a bag filter on the cooler’s air outlet to keep dust under control.

Tips for Making Great Chicken Feed Pellets

The Biggest Secret is Your Mash’s Moisture.

The feed mash that goes into the chicken feed pelletizer mill should have a moisture content of 15–17%. For safe storage, the pellets must have a moisture level of 13% or lower after the cooling stage.

Don’t Forget the Crumbler for Your Chicks!

To make starter feed, pellets are made first and then put through a crumbler until they are 2.5–3.0 mm in size. To keep the amount of fine particles at 3% or less, you should change the roll gap on the crumbler and the screening process.

You Must Always Cool Your Pellets.

Lastly, pellets should only be put in bags when they are cool enough. They shouldn’t be more than 5–10°C warmer than the room temperature. This is a very important step to keep condensation from building up inside the storage bags.

Conclusion

If you are a serious chicken farmer, a chicken feed pellet machine is worth the money. It helps you keep your costs down, make sure your feed is of good quality, and make your flock perform better overall.

The size of your farm will determine which chicken feed making machine is best for you. In the end, how well you make great pellets will depend on how well you prepare your feed mash with the right formulation and, most importantly, the right amount of moisture.

FAQ About Chicken Feed Pellet Machine

Q1. Do I need a crumbler for broiler starters?

Yes. Target 2.5 to 3.0 mm with no more than 3% fines after screening.

Q2. Why are my pellets brittle or dusty?

Most of the time, the inlet moisture is low or the system is too cold. Increase the moisture level by 1 to 2 percentage points, check the conditioning, and adjust the airflow in the cooler.

Q3. How do I reduce dust inside the house?

Put up transfer points, seal drop chutes, and put a small bag filter at the cooler discharge.