The Secret to Modern Fish Feed: Why Floating Pellets Win

Before you think about making your own feed, it’s worth asking a simple question: why floating pellets? For years, many farmers used simple sinking feeds. The amount of waste was often heartbreaking. You would throw the feed into the pond and just hope your fish found it before it disappeared into the mud. Floating pellets change this entire equation. The secret isn’t a new ingredient; it’s in how the feed is cooked.

The High-Heat, High-Pressure Advantage

Inside a machine called an extruder, something amazing happens. For about thirty seconds, the raw feed mixture is blasted with intense heat—we’re talking 120-175°C—and put under incredible pressure. Think of it as a high-speed “flash cooking” process.

This intense cooking causes the starches from ingredients like corn and wheat to expand and puff up, almost like making popcorn. These expanded starches trap tiny pockets of air inside the pellet. That is what gives it its buoyancy, allowing it to float.

More Than Just Floating: Better Nutrition

This process does more than just help the pellet float. It also essentially “pre-digests” the feed.

The heat and pressure break down complex starches and proteins, making it much easier for the fish’s digestive system to absorb the nutrients. The heat also neutralizes some of the natural compounds in grains that can make digestion more difficult for fish.

The Bottom Line: A Smarter Pellet

So, what does this mean for you and your fish? You get a much smarter feed pellet that:

- Floats on the surface where you can see it, dramatically reducing waste.

- Holds together in the water without dissolving quickly.

- Is easier to digest, meaning more nutrition goes into growing your fish, not into polluting the water.

The result is faster, healthier growth for your fish and cleaner, clearer water for your pond.

Benefits of Floating Pellets: Reduced Waste & Better Growth

High starch gelatinization

Treating raw materials at high temperatures increases starch gelatinization to 80-99%, aiding fish digestion.

Improve water stability and environment

Floating pellets decompose less in water, letting farmers check fish health and feed intake.

water absorption

Controlling the extrusion moisture content over a wide range during processing helps improve the water stability of the final feed. These particles absorb more water, hold their shape longer, and reduce nutrient loss. It benefits pellet technology quality and fish health.

better digestion and absorption

Fish feed pellets break down quickly in the stomach, losing fewer nutrients and enhancing nutrient absorption.

Feeding environment

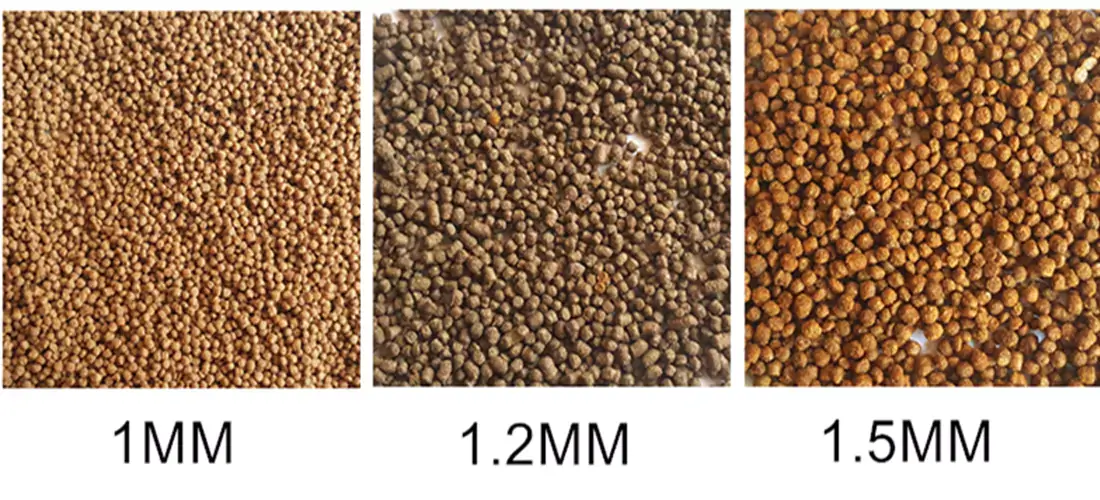

Fish are raised in water, so feed pellets must have a certain stability to maintain their shape and nutrition. Smaller fish feed particle size helps improve stability.

how to make fish feed video

Step-by-Step Floating Fish Feed Production Process

Selecting and prepare raw materials according to the fish feed ingredients:

soybean meal, cottonseed meal, corn kernels, wheat flour, fish derivatives, plant derivatives, algae, oils, minerals, proteins

Grinding raw materials:

You need to grind raw materials into powder form before producing feed pellets. The grinding process of raw materials is crucial for making feed pellets. the process determines the success of the pellet production. Therefore, a fish feed crusher is necessary. and you can check how to choose right fish feed grinder.

mixing raw materials:

Because there are many kinds of raw materials, it is necessary to mix the raw materials fully and evenly. You can mix vitamins and minerals in small amounts with the feed ingredients during mixing. If you don’t want to make your own fish feed pellets, after crushing the raw materials,you can use the fish feed mixing machine mixing your own fish feed.

Extrusion process:

The feed mixture is passed through a fish feed pellet extruder. Set the proper diameter for the die, and during the fish feed extrusion process, the pellets are chopped or broken into smaller lengths.

Drying of finished pellets:

It is difficult to store and pack granules with too high moisture content. Drying the granules with a fish feed dryer to a moisture content of less than 10% or less. The temperature should be stored below 60ºC.

Fish feed pellet packaging:

the produced feed can not be used up at one time, the feed pellets can be put into bags or containers, which can prevent insects, mice, moisture, and long-term storage. this is the last step and last one equipment in fish feed production line.

floating fish feed formulation and fish feed ingredients

Nutritional Level of Animal Proteins

| Animal Protein | Energy Level (mj/kg) | Crude Protein (%) | Fats (%) | Calcium/Phosphorus (%) | Methionine (%) | Lysine (%) |

| Meat meal | 11.2 | 50 – 51 | 10 | 8 | 0.7 | 2.6 |

| Blood meal | 15.2 | 88 – 90 | 1 | 0.4 | 0.6 | 7.1 |

| Feather meal | 13.7 | 80 – 85 | 7 | 0.4 | 0.6 | 2.3 |

| Poultry meal | 13.1 | 60 – 64 | 13 | 2.0 | 1 | 3.1 |

| Fish meal | 5 | 55 – 75 | 3 | 1.0 | 1.5 | 2 |

Nutritional Level of Plant Proteins

| Plant Protein | Protein (%) | Energy (cal/kg) | Calcium (%) | Lysine (%) | Methionine (%) |

| Soybeans meal | 44 – 48 | 2557 | 0.20 | 3.2 | 1.4 |

| Cottonseed meal | 40 – 41 | 2350 | 0.66 | 4.2 | 1.4 |

| Sunflower Meal | 46 – 47 | 2205 | 0.30 | 3.5 | 2.3 |

| GNC | 45.6 – 61.8 | 3860 | 1.7 | 3.2 | 1.0 |

Raw Material Sources for Floating Fish Feed Production

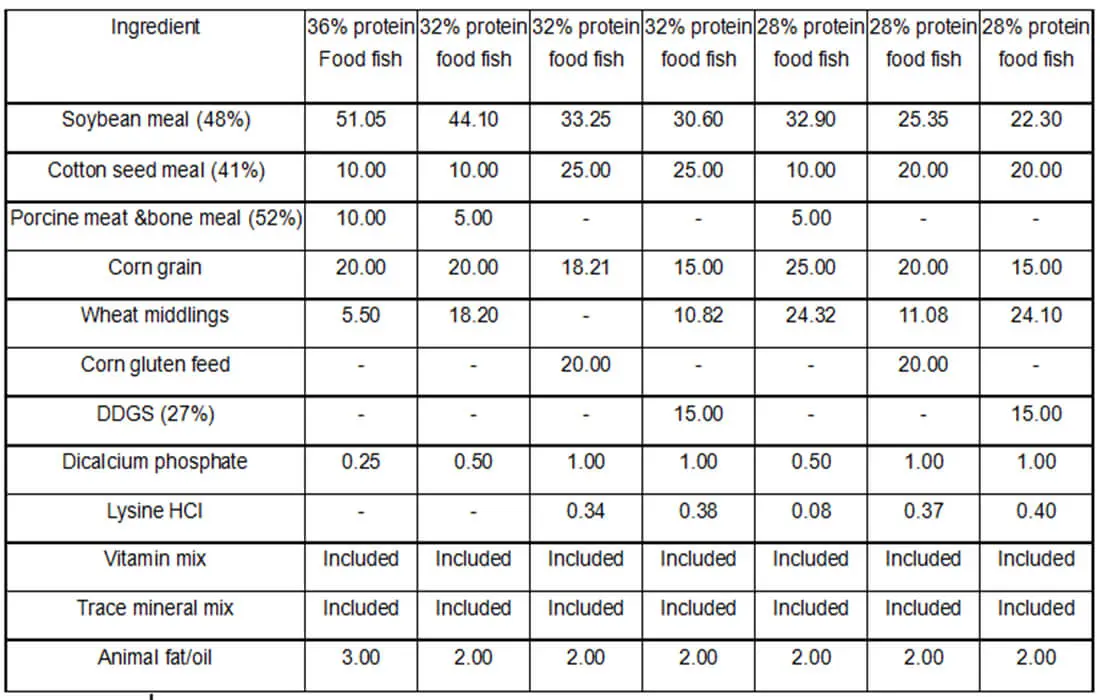

fish feed formulation ingredient compositions of catfish feed, tilapia fish feed and other fish feeds. The farmers can adjust different kinds of raw materials according to the their fish.

Fish food should provide fats for energy and amino acids for proteins. Quick digestion prevents gas, kidney failure, and infections, reducing aquarium ammonia. Carnivore feeds need plants like spirulina. According to Wikipedia, the source of raw materials fish feed ingredients for floating fish feed can be obtained from the following ways.

Fish Meal

Two fishmeal types are: (a) from fishery waste (e.g., salmon, tuna) and (b) from specific fish (herring, cod) for fishmeal only.

Shrimp mix is made from culled or unfit prawns, processed before freezing. Dry and grind fish feed ingredients for shrimp meal.Shrimp meal is a source of pigment that enhances the desired color in fish tissue. It is also a secondary source of supplemental protein for fish.

Squid Meal

Squid meal is made from the visceral parts of squid in canneries, including eggs and testicles and it offers digestible protein, amino acids, vitamins, minerals, and 1.0-1.5% cholesterol for fry and juveniles. Brine shrimp, as eggs or freeze-dried, enhance color and aid digestion with protein, carotene, and algae-derived plant matter.

Soybean Meal

Soybean meal is a high protein source for fish feed formulations. It has become an alternative to traditional marine animal diets.

Spirulina, rich in protein, vitamins, beta-carotene, minerals, and essential fatty acids, offers complete nutrition with eight amino acids. Whole grains provide roughage for fish like goldfish and koi, though not the best energy source.