Introduction of Floating Fish Feed Production

So, your small fish feed machine has been a great success. Your fish are thriving, and maybe other local farmers are even asking to buy your high-quality feed. But now you’re facing a new problem: you can’t keep up with the demand. It’s time to think about scaling up your floating fish feed production.

Scaling up is more than just buying a bigger fish feed pellet machine; it’s a strategic transition from a small operation to a serious production business. This guide will walk you through the key signs that you’re ready, the main areas you need to upgrade, and the common mistakes to avoid along the way.

Are You Ready to Scale? Key Signs to Look For

Before you invest in bigger equipment, it’s important to be sure that your floating fish feed production business is ready for the next step. Here are some key signs to look for:

- You Have Consistent, High Demand. You are consistently selling all the feed you can make. Or, your own farm’s needs are now greater than your current machine’s capacity. You are running your small machine for many hours every day just to keep up.

- You Have a Proven, Successful Feed Formula. You have a specific recipe that you know works well. It delivers good growth and a low Feed Conversion Ratio (FCR) for your fish. Other farmers may even be asking for your feed by name.

- You Have a Reliable Raw Material Supply Chain. You have established good relationships with suppliers. You are confident that you can get larger quantities of quality ingredients like maize and soy without problems.

- Your Current Operation is Profitable. You have a good understanding of your current costs. You know how much it costs you to produce one bag of feed, and you are running a profitable small-scale operation.

The 3 Main Areas of Your Floating Fish Feed Production Upgrade

Scaling up floating fish feed production involves upgrading your entire process, not just one part of it.

Upgrading Your Machinery (Beyond a Single Extruder).

Moving to a Higher-Capacity Extruder: This is the most obvious step. It might mean moving from a small extruder that makes 150 kg per hour to a larger one that can produce 500 kg or 1 ton per hour.

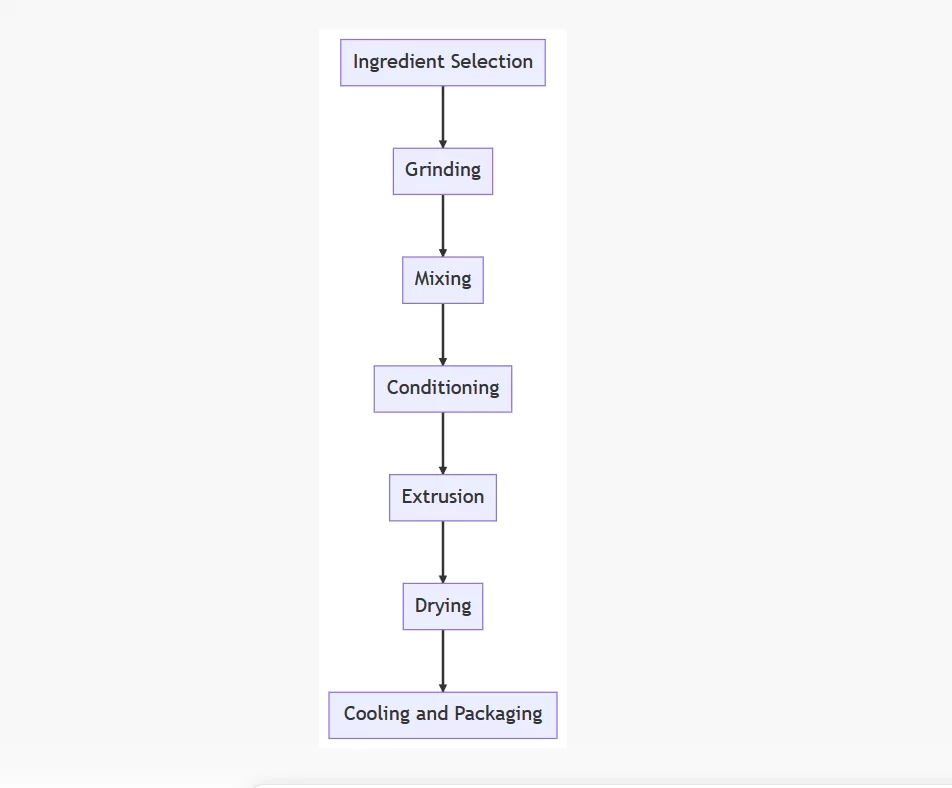

Investing in a Complete Production Line: “At this stage, you’re not just upgrading the extruder. You need a larger grinder to supply it with enough powder. You need a more efficient mixer to handle bigger batches. And critically, you need a much bigger dryer and cooler to handle the increased volume of wet pellets coming out of the new extruder.”

Considering Automation: As you scale up, you should also think about adding automation. This can include automated batching systems to weigh your ingredients and automated packing systems to bag the finished feed.

Scaling Your Raw Material Logistics.

Storage: You will be moving from buying ingredients in bags and small bins to buying them in tons. This means you will need dedicated silos for storing your grains to protect them from weather and pests.

Handling: You can no longer move materials by hand with a shovel. You will need equipment like bucket elevators and screw conveyors to move your raw materials automatically from storage to the production line.

Sourcing: You may need to move from buying from local suppliers to buying directly from larger distributors or farmer cooperatives to get better prices on your larger orders.

Planning Your Facility and Power.

Space: A larger production line requires a much bigger, dedicated building. It needs a logical layout to ensure an efficient workflow from raw material intake to finished product storage.

Power: “Your standard electrical connection is no longer enough. A large-scale production line requires a powerful three-phase electrical supply. You may also need to budget for a larger dedicated generator as a backup power source.”

Steam: “Most larger, high-capacity extruders are ‘wet type’ extruders. They work best with a steam conditioner. This means you will also need to invest in a steam boiler to supply the necessary steam.”

Planning the Investment: What Scaling Up Really Costs

Scaling up floating fish feed production is a significant financial commitment. The costs go beyond just the machines.

- The Machinery Investment: This is the cost of the entire new production line, not just the extruder.

- The Infrastructure Investment: This includes the cost of the building, the concrete foundations for the heavy machinery, the necessary electrical upgrades, and the installation of silos.

- The Operational Cash Flow: You will need more working capital. This is because you will need to buy much larger quantities of raw materials at one time to feed your larger production line.

Insider Tips & Common Mistakes to Avoid

Mistake to Avoid: “Only Buying a Bigger Extruder.”

“The most common mistake farmers make when scaling up is buying a big new extruder but keeping their old small dryer. Your production line is only as fast as its slowest machine. You must upgrade the entire line, especially the dryer, to match your new capacity. Otherwise, you will have a serious bottleneck.”

Tip: “Automate Your Bagging and Weighing Early.”

“Manually bagging hundreds of kilograms of feed per hour is slow and tiring work. An automated or semi-automated bagging system is often one of the best investments you can make for improving your efficiency as you grow. It also ensures every bag has the correct weight.”

Mistake to Avoid: “Assuming Your Old Formula Works the Same.”

“Larger, more powerful machines can sometimes process and cook ingredients slightly differently than smaller ones. Always run tests with your new, larger equipment. Be prepared to make small adjustments to your formula to get the same high-quality pellet you are known for.”

Tip: “Focus on Quality Control from Day One.”

“When you are small, you can see every pellet you make. When you are making tons of feed, you need a system. You should implement regular quality control checks for your incoming raw materials and for your finished pellets as you scale up. This is key to building a professional brand.”

Conclusion

Scaling up your floating fish feed production is a significant step that requires careful planning. It goes far beyond just buying a bigger machine. It involves upgrading your entire process, from your raw material logistics to your facility and your financial planning. However, a successful transition can turn a small on-farm operation into a major, profitable business that can reliably feed your own farm and serve your wider community.

FAQ About Floating Fish Feed Production

Q: At what production level should I switch from a single machine to a full production line?

A: There is no exact number, but a common point is when you are consistently running a small machine for many hours every day and still cannot meet demand. If you are thinking about producing more than 300-500 kg per hour, you should be planning for a complete, integrated fish feed production line, not just a bigger extruder.

Q: How much does it cost to scale up to a small commercial production line (e.g., 500 kg/hr)?

A: This is a major investment. A complete line with a high-quality extruder, dryer, mixer, grinder, and other necessary equipment at this scale can cost anywhere from tens of thousands to over a hundred thousand US dollars. The final price depends on the quality and level of automation. This does not include the cost of the building.

Q: Does scaling up production require more automation?

A: Yes, it is highly recommended. While you can run a larger line with manual labor, automation (like conveyors, automated mixers, and baggers) greatly increases efficiency. It also reduces labor costs and leads to a more consistent product, which is essential for a commercial business.

Q: Will I need a steam boiler when I scale up?

A: Most larger, high-capacity floating fish feed extruders are wet type extruders. They require a steam boiler to supply steam to a conditioner. This results in a better quality and more consistent pellet, and often a higher production capacity.

Q: How do I maintain feed quality when I am producing much larger volumes?

\A: This requires creating a quality control system. You need to have clear standards for your incoming raw materials. You should also take regular samples of your finished pellets to check their floating time, durability, size, and nutritional content. This is a key part of moving from a small operation to a professional business.