| Price | 2000-30000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Floating Fish Feed Pellet Machine Overview

| Production Output | 0.1-5 t/h |

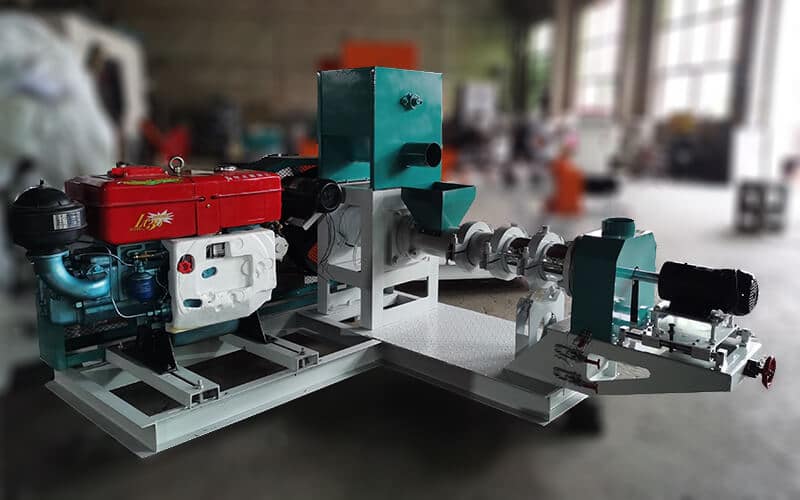

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal/cake, edible leaf, fish meal, bone powder, etc |

| Type | dry type fish feed pelletizer |

| Final product size | 0.9-15 mm |

| Application | feed pellet producing |

| Used For | floating fish feed production |

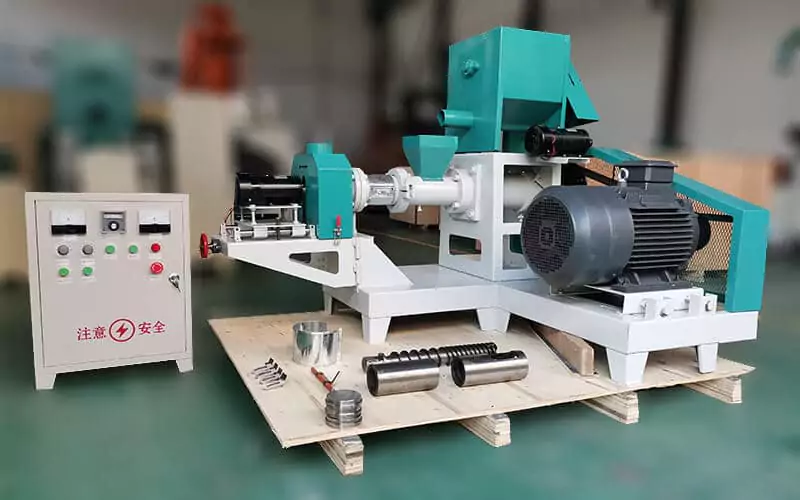

Electric and Diesel Floating Feed Machine specifications

electric fish feed machine

| Model | Capacity(kg) | Main Power(kw) | Feeding Power(kw) | Cutting Power(kw) | Screw Diameter(mm) |

| VTGP-40 | 30-50 | 4 | 0.4 | 0.4 | 40 |

| VTGP-50 | 60-80 | 11 | 0.4 | 0.4 | 50 |

| VTGP-60 | 100-150 | 15 | 0.4 | 0.4 | 60 |

| VTGP-70 | 180-250 | 18.5 | 0.4 | 0.4 | 70 |

| VTGP-80 | 300-400 | 22 | 0.4 | 0.6 | 80 |

| VTGP-90 | 400-500 | 37 | 0.4 | 1.5 | 90 |

| VTGP-120 | 500-700 | 55 | 0.4 | 2.2 | 120 |

| VTGP-135 | 800-1000 | 75 | 0.4 | 2.2 | 135 |

| VTGP-160 | 1000-2000 | 90 | 1.5 | 2.2 | 160 |

| VTGP-200 | 2000-3000 | 132 | 1.5 | 3 | 200 |

diesel engine fish feed machine

| Model | Capacity(kg) | Main Power(HP) | Feeding Power(kw) | Cutting Power(kw) | Screw Diameter(mm) |

| VTGP-40 | 30-50 | 12 | 0.4 | 0.4 | 40 |

| VTGP-50 | 60-80 | 17 | 0.4 | 0.4 | 50 |

| VTGP-60 | 100-150 | 22 | 0.4 | 0.4 | 60 |

| VTGP-70 | 180-250 | 28 | 0.4 | 0.4 | 70 |

| VTGP-80 | 300-400 | 32-35 | 0.4 | 0.4 | 80 |

| VTGP-90 | 400-500 | 50 | 0.4 | 1.5 | 90 |

| VTGP-120 | 500-700 | 75 | 0.4 | 2.2 | 120 |

floating fish Feed Production video

What Is a Floating Fish Feed Pellet Machine? Key Functions and Uses

Floating fish feed pellet machine turns grains, proteins and other ingredients into floating food pellets that fish love. Aquatic farmers always use this special fish feed processing machine to make floating aquatic food. Fish farmers rely on electric-powered puffing technology to create water-stable feed that can float on water about 12-24 hours, so fish can digest easily.

We have two types of floating feed machines: 1. dry fish feed making machine. 2. wet fish feed making machine. Our floating fish feed pellet mill is dry type which can make perfect feed for tilapia, shrimp, and even pet goldfish. If you do not want dry type, you can check our wet fish feed extruder.

The final pellet sizes range from 0.9mm to 15mm. You can feed baby fish to big fish. The same heat that floats aquatic food kills germs in aquatic meals. You should always check the temperature, proper heating can keep aquatic food safe and crunchy.

Core Working Principle

The fish feed pelletizer mill uses electric heating about 110-130°C to expand raw materials like soybean meal and wheat flour into floating pellets. the final pellet density is about 0.35-0.45g/cm³ which is best for fish digestion. This process creates air pockets that give pellets buoyancy. Proper temperature control makes sure final pellets at 92-95% floating rate.

Benefits of Floating Fish Feed Pellet Machines for Aquaculture

• Maintains 95% protein retention vs sinking feed.

• Adjustable die molds create precise pellet size.

• Handles 500-2000kg/hour depending on motor power.

electric fish feed pellet mill

diesel engine fish feed pellet mill

Main Components of Floating Fish Feed Pellet Machine

Feeder (bucket)

The feeder (bucket) is mechanical and consists of a hopper, a rotary dial, a discharge pipe, a shell, etc.

Extrusion Puffing System

The extrusion device is the core part of the floating fish feed pellet making machine. Extruding different materials uses different discharging method. selecting the correct combinantion.

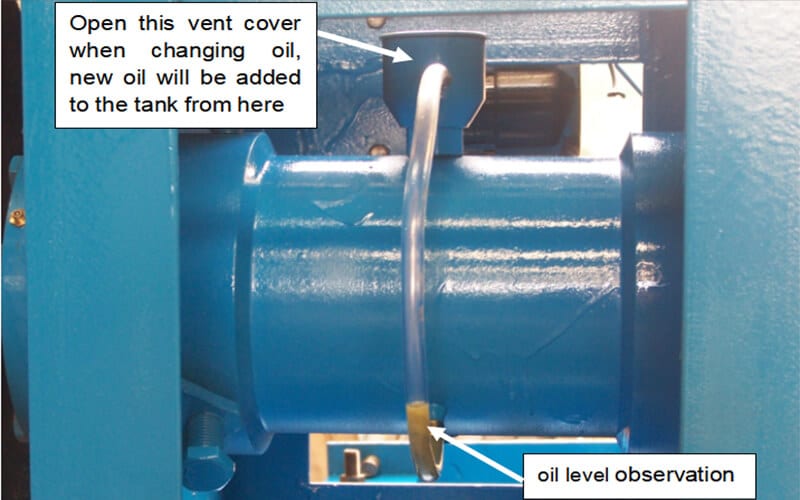

Bearing Housing Functions

Bearing box components include the body, end caps, oil filler, standard, bearing, and seal. Its function is to support the main shaft, install accessories such as bearings, lubricate and cool the bearings

Electronic Control Systems

The DGP series floating fish feed pellet machine control system varies by the main machine power and feeding form. This machine has a separate control box that attaches to the pelletizer.

Floating Fish Feed Pellet Machine Price

Floating fish feed pellet machine has prices that jump around like fish in a pond. Small machine may cost about USD 2000 which is perfect for home use or small aquatic farming with 100 fish. Large machines can cost as much as USD 30,000 or even more!

Most families and farms find their sweet spot between $2,000 to $30,000. You pay more for extra gears and stronger frames (stainless steel). You should always check the motor power and warranty years, high quality floating fish feed pellet mill comes with “no-leak” promises!

Key Points Affect the Price

Machine Capacity

Floating fish feed pellet machine is just like a bakery ovens. Small model is affordable and perfect for small farming. But large machines may cost more. The golden rule: bigger food makers eat more power but save time.

Floating Pellet Premium Explained

Making floating feed pellets is scientific that costs more. Regular floating fish feed pellet machine is like blenders, while the buoyant pellet system is more like bread makers. They need three special parts working together:

- Steam Chamber is used to puff up pellets.

- Pressure Gauge is used to control air inside.

- Cooling Belt is used to cool temperature down slowly.

We learned this the hard way – a cheap USD 8000 machine made pellets that sank after 2 hours. Now we only recommend models with all three systems properly installed.

Durable Materials for Long-Term Savings on Fish Feed Pellet Machine

The screw shaft is the heart of the floating fish feed pellet machine. Cheap carbon steel wears out fast. maybe 6 months with salty aquatic meal. But spend $800 more for nitride-coated steel, it can last 5+ years. harden gears can handle 3 tons daily pressure without breaking.

surely better parts cost more upfront, but think for long-term, you will save USD 2000 yearly on repairs and avoid 20% downtime during fixes.

Brand vs Budget: Choosing the Right Floating Fish Feed Pellet Machine

Big names like Victor Machinery charge 25% more, and here’s what you actually get:

Instant Help – Video calls vs slow emails.

Longer Promises – 5-year vs 1-year warranty.

Free Recipes – 200+ aquatic food formulas.

Best Raw Materials for Floating Fish Feed Pellet Production

Corn and soybeans are the main energy for aquatic, they are rich with 10-14% protein plus B vitamin boosters. Imagine them as breakfast cereal that makes fish scales shiny!

Mustard cake is the protein powerhouse about 30%, but needs mixing rules that never use more than 20% dry stuff. Sunflower seeds are protein kings with 54% that can build muscle strong and is perfect for growing guppies to giants.

Aquatic feed pellets gets digested faster than goldfish snacks, because its 60% protein turns into aquatic energy quickly. Bone powder is the calcium source, you can mix calcium and magnesium in 2:1 for strong skeletons.

Leftover meat bits (52% protein!) make perfect pellet glue, sticking all the good stuff together like edible tape!

In principle: the maximum size of powder should be less than 1/3 of the die hole size.

Requirement of raw material

| die hole size (mm) | grinding fineness required |

| 1.0 | 95% reach to 90-100 mesh |

| 1.5 | 95% reach to 80 mesh |

| 2.0 | 95% reach to 80 mesh |

| 3.0 | 95% reach to 60 mesh |

| 4.0 | 95% reach to 60 mesh |

| 5.0 | 95% reach to 60 mesh |

spare Parts: Screw and Die for fish feed pellet machine

The floating fish feed pellet machine main parts include the screw, die mold, sleeve, heating plate, and cutting knife, which wear out easily. When buying the fish feed pelletizer machine, get extra spare parts to avoid production halts.

For various pellet sizes and shapes, purchase additional die molds. You can produce pellet size from 0.9mm to 15mm. pellet shapes can be round, bone, heart, footprint, and triangle.

How to Adjust the Cutting Blade on Fish Feed Pellet Machine

Note: Blades should be close to the mold, slightly bent. turn clockwise by hand without pressing hard. Add a little oil between the blade and mold when using.

Note: The bearing box of small models is filled with resistant oil, it is high temperature. which can be injected through the grease nozzle on the side of the casing.