Introduction of fish feed pellet machine in Australia

the importance of fish feed production in Australia

In Australia’s fish farming industry, everything starts with the feed. The nutrition in the feed controls how healthy the fish are and how fast they grow. It’s the key to a successful farm and allows them to sell great seafood at home and overseas.

Why fish feed pellet machines are essential in modern aquaculture

Floating fish feed machine is an essential tool for modern aquaculture in Australia. They permit farmers to create their own fresh, custom feed on-site. This gives them full control over the feed’s ingredients and nutritional value. On-site production also ensures maximum freshness, which delivers the best results for the fish.

Brief overview of Aquaculture Industry in Australia

A fish feed pellet machine is a tool that helps you create a complete nutritional source for your fish. You can take your own mix of raw ingredients and make uniform, floating feed pellets. This way, you are in control and can produce feed that perfectly matches the diet your aquatic life needs to thrive.

What is a Fish Feed Pellet Machine?

Definition and Purpose: the fish feed pellet machine and its function

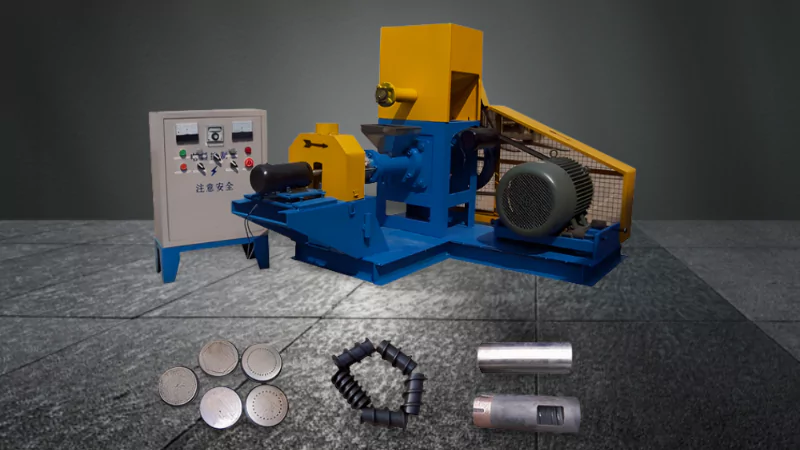

A fish feed pellet machine is a piece of equipment that makes floating pellet feed for aquatic life. Its main purpose is to convert a mixture of raw ingredients into uniform pellets. These pellets are formulated to be a complete nutritional source. The machine helps farmers produce feed that meets the specific diet of their fish.

How it Works: the process of turning raw ingredients into fish feed pellets

The process starts by mixing raw materials like fish meal, grains, and vitamins. This mixture is then fed into the machine. It uses high pressure and temperature to cook and form the mix into dense pellets. The pellets are cut to a uniform size and then dried, which locks in nutrients.

Types of Pellet Machines: Extruder vs. Pellet Mill – Key differences

There are two main types of machines for making fish feed. A standard pellet mill uses pressure to form dense pellets that sink in water. An extruder is more common for modern floating fish feed because it cooks the ingredients. This cooking process causes the pellets to expand, which allows them to either float or sink slowly. Floating feed pellets help farmers see their fish eat.

Types of Fish Feed Pellet Machines Available in Australia

Small-Scale Pellet Machines: Ideal for startups and small businesses

Small-scale fish feed pellet machine is an ideal choice for startups and smaller farms in Australia. They offer a lower initial investment and have a smaller physical footprint. These machines are also well-suited for research or for farmers testing new feed formulas. They allow smaller operations to control feed quality effectively.

Commercial-Scale Pellet Machines: For large-scale fish farms and commercial operations

Commercial-scale pellet machines are built for high-volume output. They are essential for large Australian aquaculture operations, such as those farming salmon or tuna. These machines are engineered for continuous use and can produce many tons of feed each hour. They provide the needed efficiency for a large commercial business.

Choosing the Right Fish Feed Pellet Machine for Your Needs

Production capacity and scale of operation

Your choice of fish feed pellet machine in Australia should match your farm’s production scale. You must consider your daily feed requirements. A small farm’s needs are very different from a large commercial operation. Selecting a machine with the right capacity will ensure you meet demand without overspending on equipment.

Power requirements and energy efficiency

You’ll need to know what kind of power you have on the farm. While small machines can use single-phase, the commercial models often require a three-phase hookup. Choosing a machine that uses less energy helps keep your costs down over time.

Raw materials compatibility

A good machine must be able to process these kinds of tougher, alternative ingredients, not just standard grains. This capability gives you incredible power over your operation. It means you can reformulate your feed based on seasonal ingredient prices, directly controlling your production costs. Just as importantly, it allows you to build a more sustainable farm that meets your own goals for a healthier planet.

Size and shape of pellets required

Fish require different pellet sizes at various life stages. Young fish, or fry, need a very small crumble, while adult fish eat larger pellets. A good machine lets you change parts like dies to produce a range of pellet sizes. This versatility means one machine can support your stock’s entire growth cycle.

Benefits of Using Fish Feed Pellet Machines in Aquaculture

Improved Fish Growth and Health: Better nutrient retention and digestibility

Producing your own floating fish feed pellets results in healthier fish. The extrusion process cooks the starch in the feed, which improves its digestibility. Better digestion means the fish absorb more nutrients from their food. This improves the feed conversion ratio and leads to faster, more consistent growth.

Cost-Efficiency: Reducing feed wastage and optimizing production

On-site pellet production is highly cost-efficient. You eliminate the freight costs of shipped-in feed and can produce feed on demand. It also reduces waste because the pellets are water-stable and highly palatable. More of the feed is consumed, which saves you a great deal of money.

Consistency and Quality Control: Ensuring uniformity in pellet size and texture

A pellet machine provides complete control over feed quality. You can ensure every batch has a uniform size, shape, and nutritional profile. This consistency is important for achieving predictable growth across your fish population. It also helps you maintain a high-quality final product.

Sustainability: Contribution to more sustainable aquaculture practices

These fish feed pellet machine in Australia directly support more sustainable farming practices. By using local and plant-based ingredients, you can reduce the industry’s reliance on wild-caught fish. Better feed digestibility also leads to less nutrient discharge into the water. This helps protect the local aquatic environment.

Common Challenges in Fish Feed Pellet Production

Machine Maintenance: How to ensure longevity and efficiency

Proper machine maintenance is vital for a long service life. Key components in an extruder, such as the screw and dies, experience heavy wear. A good practice is to inspect these parts regularly and keep spares on hand. A consistent schedule for cleaning and lubrication prevents unexpected downtime.

Quality Control: Ensuring optimal pellet quality consistently

Maintaining consistent pellet quality requires attention to detail. The moisture content and particle size of your raw materials can greatly affect the final pellet. You must monitor your inputs and adjust the machine’s settings to produce a good result every time.

Raw Material Availability: Sourcing the right ingredients for pellet production

Sourcing consistent, high-quality fish feed raw materials can be a challenge. The cost and supply of fish meal can fluctuate. Many Australian farmers must therefore find and test reliable, sustainable alternatives. Building good relationships with local grain suppliers is a smart strategy.

The Future of Fish Feed Pellet Machines in Australia

Technological Innovations: Latest trends and advancements in pelletizing technology

The technology in this field is constantly advancing. New innovations include vacuum coating systems, which add oils after extrusion. This method protects sensitive nutrients from heat damage. These new technologies help create more effective and nutritionally complete fish feeds.

Sustainability in Aquaculture: How Australian farmers adopt efficient feed production

Australian farmers are making great strides in sustainable feed production. They are exploring novel ingredients like insect meal and algae to replace fish meal. Modern feed machines are being designed to process these new materials. This shift is making Australian aquaculture more environmentally sound.

The role of automation in shaping the future of fish feed manufacturing

Automation is shaping the future of floating fish feed manufacturing. These advanced systems use sensors and computers to control the entire production line. This ensures optimal quality and efficiency. This approach also provides excellent traceability, which is important for food safety and export markets.

Case Studies: Successful Feed Pellet Mill Installations in Australia

Case Study 1: Tasmanian Salmon Operation

A mid-sized salmon farm in Tasmania was facing high costs from imported feed. They also struggled to optimize their Feed Conversion Ratio, or FCR. They invested in a commercial-scale fish feed production line. This allowed them to use local Tasmanian ingredients and control their own nutritional formulas. The results were dramatic. By making their own feed, the farm cut its yearly feed costs by 25%. Their FCR improved from 1.4-to-1 down to an excellent 1.2-to-1. The farm calculated that the entire investment paid for itself in just two and a half years.

Case Study 2: Queensland Barramundi Farm

A barramundi farm in North Queensland wanted to enter the premium export market. To do this, they needed to guarantee a higher fish quality with better nutritional content. They installed a smaller, specialized production line that included a vacuum coater.

This let them add specific, delicate fish oils after the pellet was formed. This new feed formula increased the healthy Omega-3 content in their fish by 15%. This allowed them to meet the strict standards of a new premium market, and they increased their sales price by 20%.

Conclusion

Choosing the right fish feed pellet machine in Australia is an important investment for your business. It is a key decision for improving the efficiency and sustainability of your Australian aquaculture operation. The right equipment gives you control over nutrition, helps reduce costs, and ensures you can deliver a high-quality product to the market.

FAQ

What are the main differences between fish feed pellet machines and other types of pelletizers?

The key difference is the process and the final product. Fish feed making machines are often extruders that cook the feed, allowing it to float that is to make floating fish feed. Pelletizers for land animals, like cattle, typically use a cold press method. This creates dense, sinking pellets that are not suited for the feeding habits of most farmed fish.

How much does a fish feed pellet machine cost in Australia?

The cost of a fish feed pellet machine in Australia varies widely. A small-scale machine suitable for a startup could range from $8,000 to $20,000. A large, automated commercial extrusion line can cost several hundred thousand dollars. The final price depends heavily on production capacity, automation, and overall build quality.

What are the best materials for making fish feed pellets?

The best materials provide a complete and balanced diet. This traditionally includes quality fish meal for protein and fish oil for essential fats. For sustainability, formulas now often include plant-based proteins from sources like soy or Australian lupins. A balanced mix also contains grains, vitamins, and minerals.

How often do fish feed pellet machines need maintenance?

We recommend a quick check and a good cleaning after every single use. Then, depending on how much you use it, plan for a more detailed inspection of the high-wear parts, like the extruder screw and dies, either weekly or monthly. Your best bet is always to follow the schedule in the manufacturer’s guide—that’s how you’ll ensure the equipment has a long life.