Introduction of Feed Manufacturing Process

Have you ever wondered how a pile of raw grains like corn and soybeans becomes a uniform, nutritious pellet for your animals? It’s a precise industrial process. This process is designed to maximize nutrition and minimize waste. While the basic steps are similar for many types of animal feed, there are key differences, especially when making feed for poultry.

This guide will walk you through the complete feed manufacturing process. We’ll cover each important step from receiving the raw materials all the way to bagging the final product.

The Goal of the Process: Why Not Just Feed Raw Grains?

Here are the main steps that happen inside a modern feed plant.

Step 1: Receiving and Inspecting Raw Materials

The process begins when raw ingredients arrive at the feed plant. This includes grains, protein meals, and minerals. Each ingredient is inspected for quality. It is checked for things like moisture content and for any contaminants. After it passes inspection, it is sent to large storage silos or bins.

Step 2: Grinding (or Particle Size Reduction)

Next, a machine called a hammer mill is used to grind the core ingredients. It turns them into a fine, uniform powder. “Think of it like making flour before baking a cake – you need a consistent base for a good final product.”

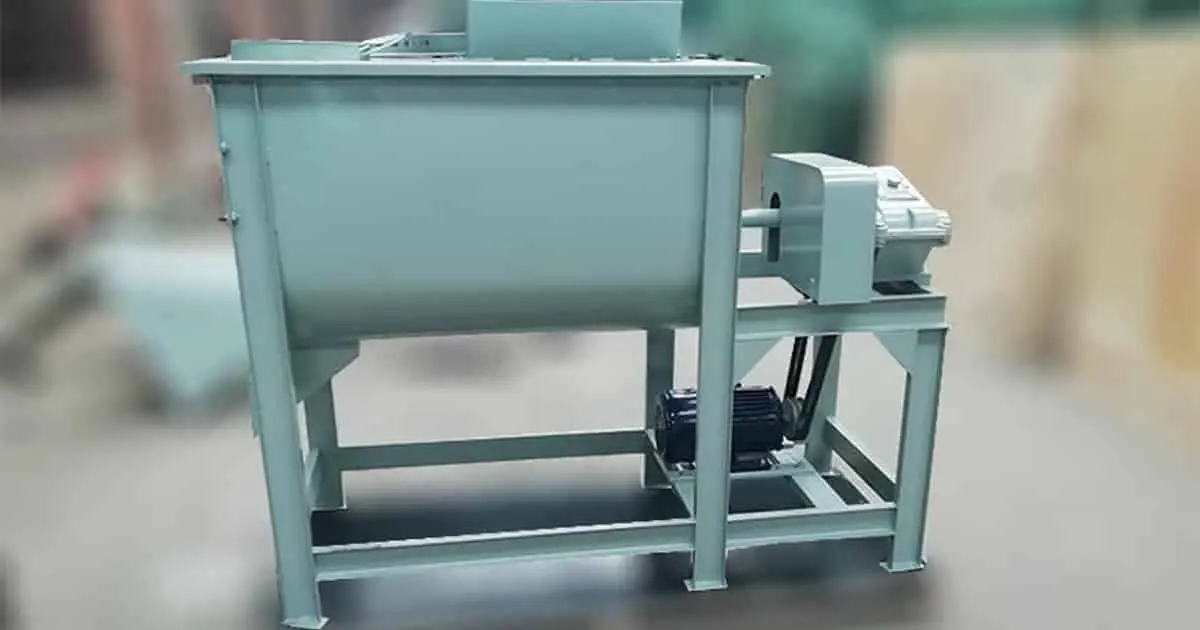

Step 3: Batching and Mixing

The ground ingredients are then weighed very precisely according to a specific feed formula. They are moved to a large mixer. Here, all the ingredients, including the important vitamins, minerals, and other micro-ingredients, are thoroughly blended together. This creates a uniform “mash.”

Step 4: Conditioning

The mixed mash is then passed through a machine called a conditioner. In this machine, steam is added to the feed. The steam adds heat and moisture. This starts the cooking process. It also prepares the mash for being pressed into pellets.

Step 5: Pelleting

The warm, moist mash from the conditioner is then fed into a pellet mill. This machine uses heavy rollers and a metal plate with holes (called a die). It presses the mash through the holes with high pressure to form dense, solid pellets.

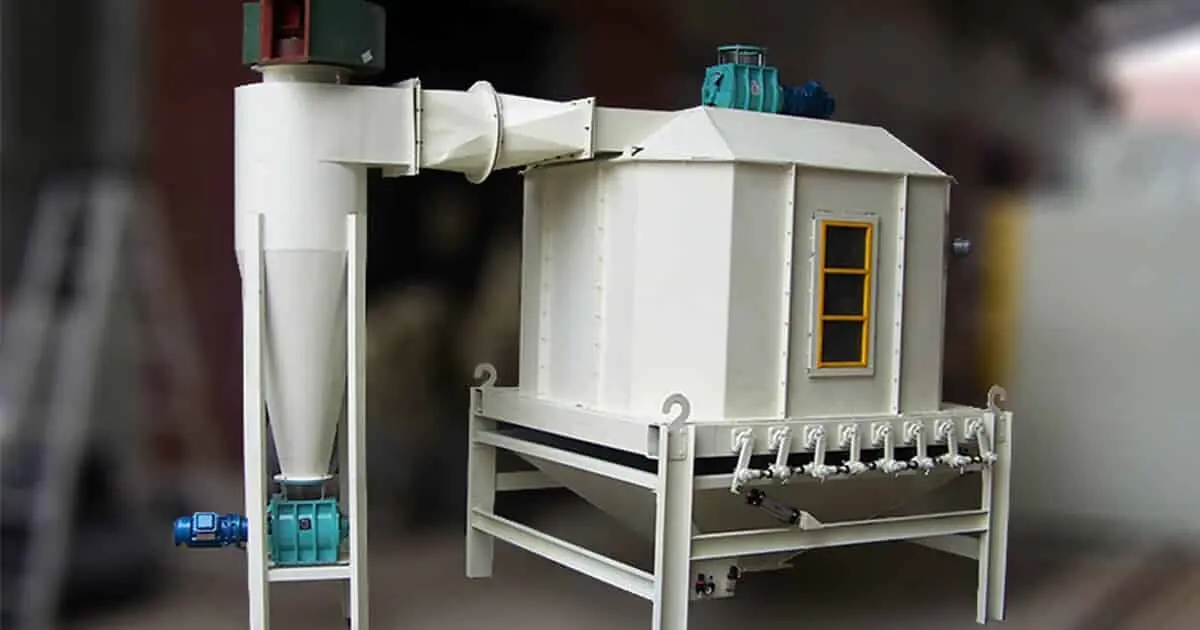

Step 6: Cooling and Drying

The pellets come out of the pellet mill hot and moist. They are then moved to a cooler. Air is passed over them here. This reduces their temperature. It also removes excess moisture. This makes the pellets hard and stable so they can be stored.

Step 7: Bagging and Storage

Finally, the finished, cooled pellets are weighed and packed into bags. They are then ready to be stored or shipped to the farm.

Key Differences in the Poultry Feed Manufacturing Process

While the general process above applies to most feeds, making poultry feed has some special steps.

Finer Grinding Requirements

Poultry, and especially young chicks, have smaller digestive systems. They benefit from feed that is made from more finely ground particles. This is compared to feed for larger animals like cattle.

The Crumbling Process (A Special Step for Starter Feeds)

“This is a special step that is very common in poultry feed production.” After the pellets are made and cooled, they are often sent to a machine called a crumbler. This machine uses special rollers. These rollers crack or break the finished pellets into smaller, irregular pieces. These pieces are called “crumbles.”

Why it’s done:

“These crumbles are the perfect bite-size for baby chicks. Young chicks cannot eat a full-sized pellet.”

Precise Screening/Sifting

It is important to sift the finished poultry feed carefully. This is to get uniform crumble sizes for chicks of different ages. It also removes fine dust. Poultry can be sensitive to too much dust in their feed.

Different Formulations in the Mixing Stage

It is also important to remember that the recipes used in the mixing stage are very different. For example, feed for laying hens requires much higher levels of calcium than feed for broiler chickens.

Quality Control: The Unseen but Vital Step

Good feed mills have a quality control lab. Throughout the manufacturing process, they take samples at each stage. They take samples of raw ingredients when they arrive. They also take samples of the finished pellets before they are bagged.

These samples are tested to make sure the feed is safe. They are checked to be sure they are free from contaminants. They are also tested to make sure they meet the exact nutritional promises of the formula.

FAQ

What is the main difference between making poultry feed and cattle feed?

A: There are two main differences in the process. Poultry feed usually requires the ingredients to be ground more finely. It also often includes a special “crumbling” step. This step breaks down pellets into smaller pieces for starter feed for chicks. Cattle feed, on the other hand, uses larger pellets and can include more high-fiber ingredients (roughage).

Why is conditioning feed with steam so important?

A: Steam conditioning does two very important things. First, it starts to cook the starches in the feed. This makes the nutrients easier for the animals to digest. Second, the heat and moisture help the particles stick together better. This results in a stronger, more durable pellet that does not fall apart easily.

What is a “crumbler” machine used for?

A: A crumbler is a machine used after the pellet cooler, mainly in a poultry feed plant. It uses special rollers to gently crack or break finished pellets into smaller, irregular pieces called “crumbles.” These crumbles are the perfect size for young chicks to eat before they are big enough to eat whole pellets.

Is the process the same for making simple mash feed?

A: No. To make mash feed, the process is much shorter. You simply stop after the mixing step. The grinding and mixing steps are the same, but for mash, you skip the steps of conditioning, pelleting, cooling, and crumbling. You can learn how to make poultry feed.

How is feed quality checked during the manufacturing process?

A: Good feed mills have a quality control lab. They take samples at different stages of the process. This includes from the raw ingredients when they arrive to the finished pellets before they are bagged. These samples are tested for things like moisture content and protein levels. They are also checked to make sure they are free from any harmful contaminants.

Conclusion

The manufacturing process for animal and poultry feed is a carefully controlled, multi-step industrial process. It is designed to turn raw ingredients into safe, nutritious, and consistent feed pellets that help animals grow well.

While the general process of grinding, mixing, and pelleting is similar for many animals, the manufacturing of high-quality poultry feed often includes special, important steps like crumbling to meet the unique needs of the birds at different stages of their lives.