| Price | 1000-50000 USD |

| Delivery Time | 10-15 days |

| Available | In Stock |

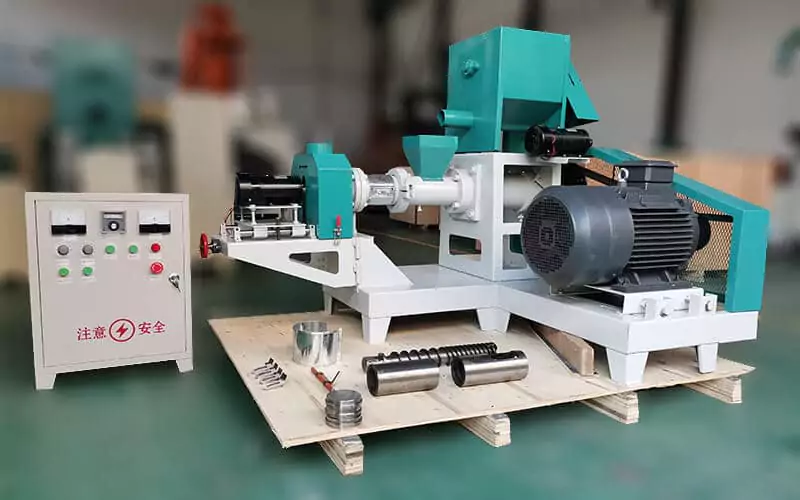

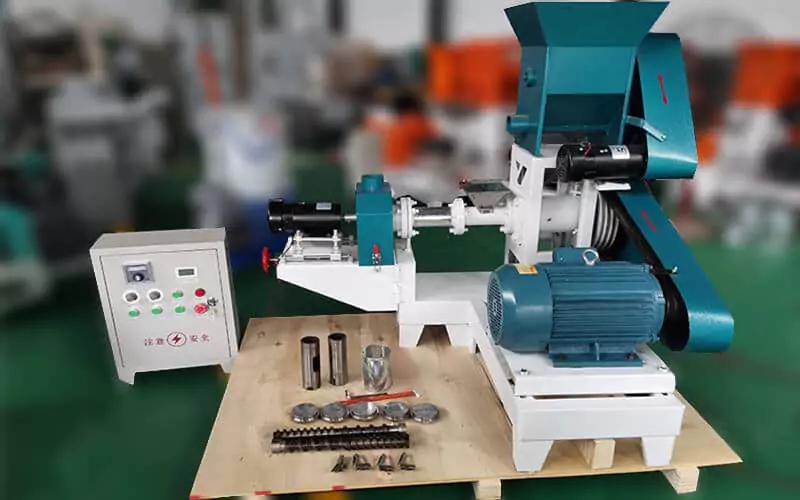

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Shrimp Feed Pellet Machine Overview

| Production Output | 0.1-5 t/h |

| Power | Electric motor or diesel engine |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal, fish meal, bone powder, etc |

| Type | sinking type feed |

| Final product size | 0.9-15 mm |

| Application | feed production |

| Used For | aquatic prawn feed |

specification of shrimp feed pellet mill

| Model | Power(Kw) | Output(kg/h) | Feeding Power(kw) | Conditioner Power(kw) | Ring Die Diameter(mm) | Pellet Size(mm) |

| HMK-250 | 22 | 500-1000 | 0.55 | 2.2 | 250 | 1.5-8 |

| HMK-300 | 30 | 1000-2000 | 0.75 | 2.2 | 300 | 1.5-8 |

| HMK-320 | 37 | 2000-3000 | 0.75 | 2.2 | 320 | 1.5-8 |

| HMK-350 | 55 | 3000-4000 | 1.5 | 3 | 350 | 1.5-8 |

| HMK-400 | 75 | 4000-5000 | 1.5 | 5.5 | 400 | 1.5-8 |

| HMK-420 | 110 | 5000-8000 | 1.52.2 | 5.5 | 420 | 1.5-8 |

A High-Growth Aquaculture with Specialized Needs

Fish farming is booming in the world and fish farmers need smart shrimp feed pellet machine to make fish food. The special shrimp feed pellet mill can produce perfect food for prawn tummies. This water crop field grows faster than any other food business.

Experts say this field will grow twice as big in following 10 years. Big growth needs special mill that can work faster and smarter. The prawn food pellet machine is the key for tomorrow’s fish farmings. We also sell floating pellet machine for other aquticfeed.

these shrimp feed pellet mill machines are custom-designed for prawn meals. Prawn are different from other aquaculture and they need special food to grow strong.

Understanding the Shrimp Feed Pellet Machine

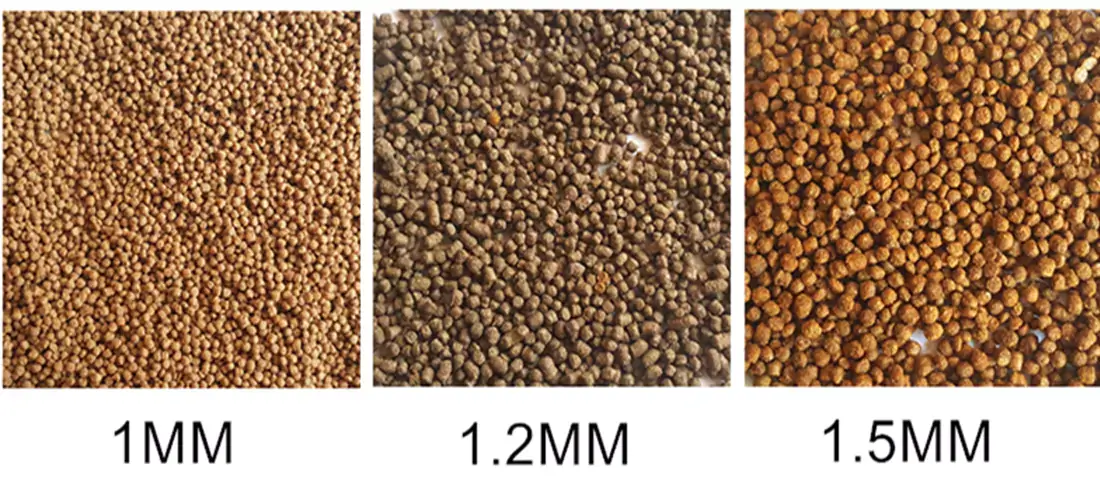

The main job of shrimp feed extruder machine is to turn raw materials into small feed pellets. the shrimp pelletizing system support 1.5-8mm pellet size. 0.9-2.5mm pellet size is best for juvenile shrimp stage, 4.0-6.0mm pellet size is best for adult shrimp stage.

Precision feed size control tolerance ≤0.1mm, and it is 35% lower energy consumption, it reduces maintenance time by 60%. These food are easy for prawn to eat and break down.

The magic is each bite has the same mix of good stuff, keeping prawn healthy. at now prawn farming is growing fast, the shrimp feed making machine is the key point for big operations. Large Prawn farmings can use fish food line to produce Prawn meals.

Feed Pellet Size Matters a Lot

When talking about prawn food, the food size is the key point. It decides if the food is good for prawn. Baby or adult shrimp all need right size food. shrimp feed pellet mill can make bigger or smaller food as prawn grow.

Prawn Growth Stages & Optimal Pellet Size

Science shows prawn grow best with right food size. A 2023 AquaTech study found perfect-sized feed make food work 35% better in big shrimp farmings.

Data Comparison Table

| Stage | Body Length | Recommended Pellet Size | Feed Efficiency Improvement* |

|---|---|---|---|

| Post-Larvae | 1-2 cm | 0.9-1.2 mm | +40% (vs. random sizing) |

| Juvenile | 3-5 cm | 1.5-2.5 mm | +32% |

| Sub-Adult | 6-8 cm | 2.8-3.5 mm | +28% |

| Adult | 9-12 cm | 4.0-6.0 mm | +25% |

Customizing Pellets for prawn Species: A Scientific Approach

prawn types need different foods and eat in special ways.

FAO’s 2024 fish farming report shows special food bits can help 18-22% more baby prawn grow up healthier than regular food.

Check our new matching chart to make perfect prawn food:

Prawn Species-Specific Pellet Matrix

| Species | Protein Requirement | Fat Content | Pellet Hardness (kg/cm²) | Sinking/Floating | Victor Model |

|---|---|---|---|---|---|

| Litopenaeus vannamei | 35-40% | 5-7% | 4.5-5.2 | Sinking | HMK-350+ |

| Penaeus monodon | 38-45% | 6-8% | 5.8-6.5 | Sinking | HMK-400+ |

| Marsupenaeus japonicus | 40-42% | 4-5% | 3.8-4.3 | Slow-sink | HMK-320 |

| Macrobrachium rosenbergii | 28-32% | 3-4% | 2.5-3.0 | Floating | HMK-250 |

Shrimp Feed Pellet Machine Cost and Suppliers: What to Expect

many things can affect shrimp feed machine prices.The machine size, parts, supplier, and where it’s made, all will affect the cost.

so you should always ask different sellers and check their deals side by side. a lot of factories sell these machines straightly from their workshops, cutting out middlemen to save you money.

Shrimp Feed Pellet Machine Investment

Shrimp farmers should get a shrimp feed extruder machine. It can make feeding easier and give same good food every time. mixing and making with good recipes, your prawn will grow faster and stronger.

Technological Advancements of Shrimp Feed Pellet Machine

In fish farming, top quality food is very important. It can affect how healthy the shrimp are, how fast they can grow, and how many prawn you can get.

at now fish farmings are growing, shrimp feed pellet making machine got huge upgrades to work better, cost less, and keep food bits the same.

Let’s check out these cool new advantages:

1. Precision Pellet Sizing

Old shrimp feed pellet mill couldn’t change food sizes too much. but new advanced machines can do the right food size exactly.

farmers can make right food size for baby and adult prawn through changind different mold.

2. Automated Control Systems

New advacned shrimp feed pellet machine now have smart robot brains. They let workers watch and tweak heat, squeeze, and wetness as it happens.

Tap screens, feeler gadgets, and smart computer brains make food bits faster and smoother.

3. Enhanced Durability of The Machine

When the shrimp feed extruder machine works day and night, their parts get rubbed thin.

shrimp feed pellet mill manufacturers found a smart fix:

- 1.Cover food molds and press wheels with armor-like super materials

- 2. Machines now last 3x longer

- 3. Food bits stay perfect year after year

4. Energy Efficiency

Big prawn farmings worry about how much power they will use.

The newest shrimp feed pellet machine now focus on saving energy with:

- making gears spin like butter.

- use super motors that sip power.

- Brainy coolers that only work when needed.

5. Integrated Safety Features

Keeping workers safe is the number one job in factories. New advanced shrimp feed pellet mill have built-in safety parts: big red stop buttons, power surge stoppers, and danger shields.

These can protect people and machines while making work areas much safer.