| Price | 26000-96000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Poultry Feed Pellet Plant Overview

| Production Output | 2-3 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal, fish meal, bone powder, grass meal, hay meal, etc |

| Type | flat die type and ring die type |

| Final Pellet Size | 2-10 mm |

| Application | animal and poultry feed pellets |

| Used For | chicken feed, bird feed |

Working video of poultry feed pellet plant

Introduction

For anyone running a serious poultry farm, the feed bill is a constant headache. It’s your biggest cost, and the quality of commercial feed isn’t always something you can control. This is the core challenge that a dedicated poultry feed pellet plant is designed to solve. It is a strategic investment for poultry operations that want to gain control over feed quality, create custom nutrition, and achieve significant long-term cost savings.

This guide is a no-nonsense look at what it really takes to set one up. We’ll cover the real benefits for your flock. We will also look at the essential machinery, the step-by-step production process, and the critical questions you need to ask before investing.

What is a Poultry Feed Pellet Plant? (More Than Just a Machine)

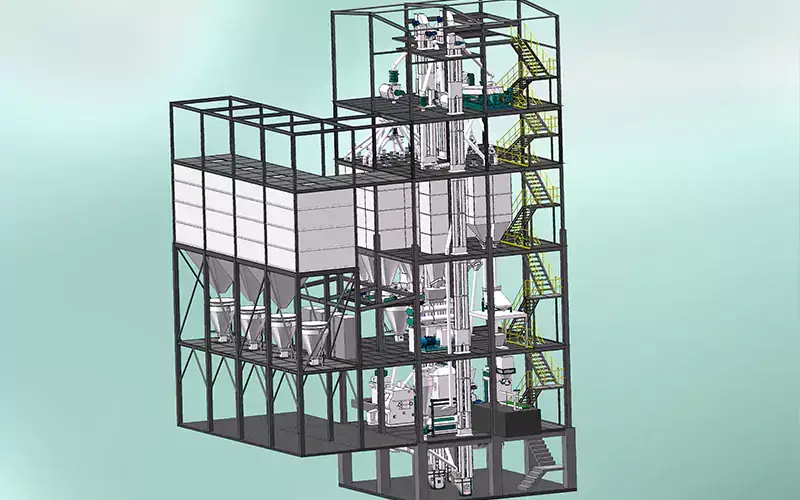

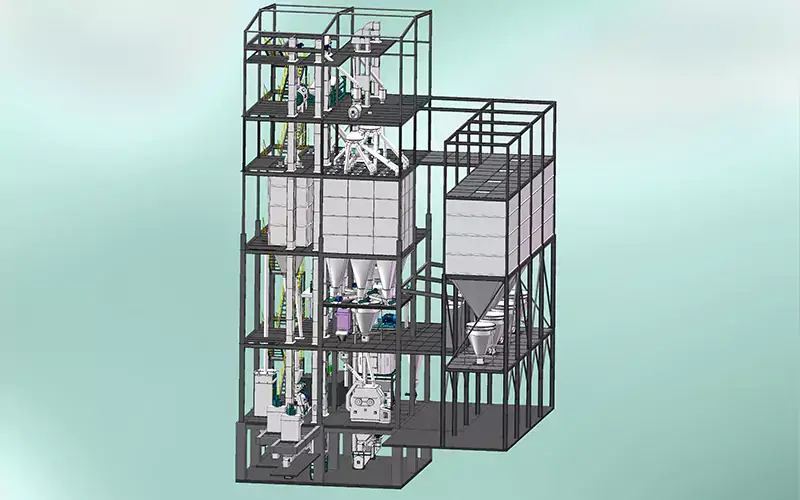

It’s important to understand that a poultry feed pellet plant is more than just a single machine. It is a complete, integrated facility. It has a series of interconnected machines and systems. These are all designed for the efficient and consistent production of poultry feed pellets, from processing the raw ingredients to bagging the finished product.

A “plant” is different from small-scale, on-farm pelleting. A plant usually means you have a higher production capacity. It often has more automation. It also has the ability to handle a wider range of processes and quality control measures for your feed.

The Real Advantages of Owning Your Poultry Feed Plant

Having your own feed plant offers powerful advantages for your poultry business.

Take Control of Your Biggest Cost

This is a huge benefit. You can purchase raw ingredients like corn and soybean meal in bulk at wholesale prices. This avoids the markups and price changes often seen with commercial bagged feed. Over time, this can greatly reduce your number one operational cost.

Formulate for Performance: Broiler vs. Layer Feeds

With your own plant, you have the power to create precise and fresh feed recipes. You can tailor these recipes for the very different nutritional needs of meat birds (broilers) and egg-laying hens (layers). You can also adjust the feed for their different growth stages. This ensures your flock gets optimal nutrition for the best performance.

Ensure Feed Quality and Safety

You know exactly what’s in your feed. This allows you to avoid unwanted fillers, contaminants, or low-quality ingredients that might be found in some commercial feeds. This control leads to healthier birds.

A Consistent, Reliable Feed Supply

Owning your own plant means you no longer have to worry about your supplier running out of stock. You also don’t have to worry about delivery delays. This is especially important during critical growth periods for your chickens.

Less Food Waste

strong hard pellets don’t crash easily. the pellets are fresh in storage and trays. so farmers can save money because every bite can get eaten.

| Metric | Traditional Feed | Pellet Feed |

|---|---|---|

| Transport Breakage | 28% | 4% |

| Trough Residuals | 19% | 3% |

| Mold Contamination | 33% | 0% |

| Data source: Kampala Poultry Research Institute |

Inside the Plant: Key Machinery for Making Poultry Feed

A modern poultry feed plant has several key sections with specialized machines.

Raw Material Handling & Storage Systems:

This is where grains and other ingredients are received and stored. It includes intake pits, silos for grains, and conveying systems like screw augers and bucket elevators.

The Grinding Section (Hammer Mill):

A hammer mill is used to grind raw ingredients like corn and wheat into a uniform, fine particle size. This is crucial for poultry because they need finely ground feed for good digestion, especially when they are young.

The Mixing Section (High-Efficiency Mixer):

After grinding, all the ingredients are blended together in a large mixer. This is a critical step to ensure that important micro-ingredients, like vitamins, minerals, and amino acids, are perfectly distributed throughout the feed.

The Conditioning Section (Steam Conditioner):

This is a key step for making high-quality poultry feed. The conditioner uses steam to add heat and moisture to the mixed feed mash. This process helps to cook the starches, which makes the feed easier for chickens to digest. It also helps to kill harmful bacteria.

The Pellet Mill:

This is the heart of the plant. It takes the conditioned mash and uses high pressure from rollers to press it through a die (a metal plate with holes), forming dense pellets.

The Pellet Cooler (Counterflow Cooler):

Pellets come out of the pellet mill very hot and somewhat soft. A cooler uses air to reduce their temperature and remove excess moisture. This step is what makes the pellets hard and stable for storage.

The Crumbler (A Must-Have for Starter Feeds):

“This machine is essential for anyone raising chicks. Whole pellets are often too large for young birds to eat. A crumbler takes the finished pellets and gently breaks them into smaller, more manageable ‘crumbles,’ which are perfect for starter feeds for both broiler and layer chicks.”

The Sifting/Screening Section (Rotary Sifter):

After cooling and crumbling, the feed is passed through a sifter. This removes any fine dust and ensures that all the pellets or crumbles are a uniform size. This results in a high-quality final product.

The Packing Section:

The final step is usually an automated or semi-automated bagging system. It weighs the finished feed accurately and packs it into bags for storage or sale.

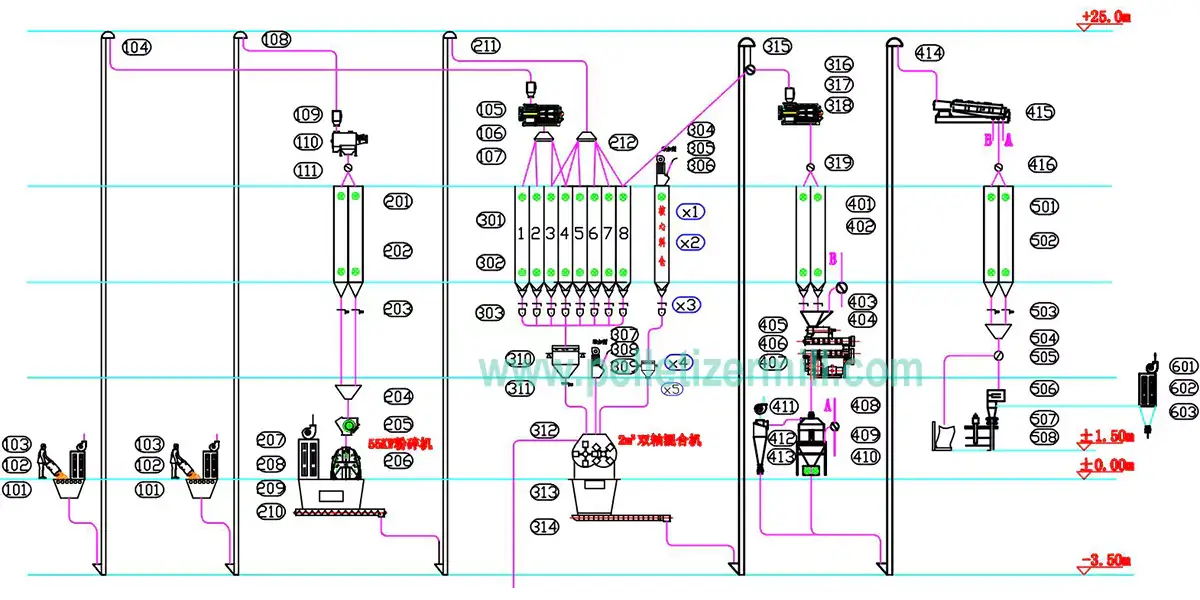

The Poultry Feed Production Process: A Step-by-Step Flow

Here is a general look at how the production process works in a plant:

- Receiving and Quality-Checking Raw Materials: Ingredients are delivered, checked for quality, and stored.

- Grinding: Grains and other core ingredients are ground to the target particle size.

- Batching & Mixing: The correct amount of each ingredient for a batch is weighed out, following your specific broiler or layer formulation. Everything is then blended into a homogenous mash.

- Conditioning with Steam: The mash is conditioned with steam to prepare it for pelleting.

- Pelleting: The conditioned mash is pressed through the pellet mill to form pellets.

- Cooling: The hot pellets are cooled to make them hard and stable.

- Crumbling: This step is used only if you are making chick starter feed. The cooled pellets are broken into crumbles.

- Sifting: The finished feed is screened to ensure it is uniform and free of dust.

- Bagging and Storing the Finished Feed: The final product is packaged and stored.

poultry feed manufacturing process flowchart

Planning Your Poultry Feed Plant: Critical Questions to Answer

Setting up a feed plant is a major project that requires careful planning.

What is Your Real Production Need? (Capacity in tons/hr)

How many birds are you feeding now, and how many do you plan to have in the future? This will determine the size and capacity of the plant you need.

What Kind of Feed Will You Make Most? (Broiler, Layer, Starter Crumbles?)

Your main product will influence your machinery choices. For example, if you raise a lot of chicks from day one, an efficient crumbler is an essential part of your plant.

Can You Source Quality Raw Materials Consistently & Affordably?

“This is the make-or-break question for any feed plant. Do you have reliable access to a steady supply of good quality corn, soybean meal, and other ingredients at a price that makes financial sense? Your entire business depends on this.”

Have You Planned for a Proper Facility?

Think about the space you need for all the machinery. You will also need space for raw material storage and for storing your finished product. You will also need a reliable power supply (often three-phase) and a steam boiler for the conditioner.

Who Will You Buy Your Machinery From?

Look for a reputable supplier. They should have experience specifically with building poultry feed plants. Good after-sales service and spare parts availability are non-negotiable.

Have You Done a Real Cost vs. Benefit Analysis?

Carefully calculate the total investment cost for the plant. Compare this to your potential long-term savings on feed costs to understand if it’s a good financial decision for your operation.

FAQ

1. What’s the main difference between a single poultry feed machine and a full plant?

The main differences are scale, integration, and automation. A “machine” usually refers to a single, standalone pellet mill. A “plant” is a complete, integrated system of multiple machines, including grinders, mixers, coolers, and more. A plant is designed for higher, more consistent output with less manual labor, from raw material intake all the way to the finished, bagged feed.

2. Can I make both broiler and layer feed in the same plant?

Yes, absolutely. The same plant machinery is used for both. The key difference is the feed formulation – the specific recipe of ingredients and their proportions. You would simply change the recipe that the plant is processing to switch between making broiler feed and layer feed. You might also change the pellet die size or the crumbler settings.

3. Why is a “crumbler” so important for a poultry feed plant?

A crumbler is essential because young chicks, for both broilers and layers, cannot eat full-sized pellets. A crumbler takes these finished pellets and gently breaks them into the ideal “crumble” size. This allows them to eat easily and get the nutrition they need for a strong start. It is much more efficient than trying to make tiny pellets directly in a large pellet mill.

4. How much does it cost to set up a small poultry feed pellet plant?

This can vary hugely. A small but complete plant (for example, one that makes 1-2 tons of feed per hour) is a very significant investment. The cost can range from tens of thousands to hundreds of thousands of US dollars. The final price depends on the level of automation, the quality of the machinery, and where it is made. It is essential to get detailed quotes from several different suppliers.

5. Do I need a nutritionist to run a feed plant?

While you don’t necessarily need a nutritionist on staff 24/7, you absolutely need to work with a qualified poultry nutritionist to create your feed formulations. They will help you create recipes that are safe, effective, and nutritionally balanced for your birds. This is not a step you should ever skip when making your own feed.