| Price | 26000-96000 USD |

| Delivery Time | 20-25 days |

| Available | In Stock |

| Package | In Free Fumigation Wood Box |

| Guarantee | 1 Year |

| Shipping | By Sea or By Air |

| Payment Method | Wire Transfer or Western Union |

| Brand | Victor |

Poultry Feed Pellet Plant Overview

| Production Output | 2-3 t/h |

| Power | Electric motor |

| Voltage | 110-415V |

| Raw Materials | Cereal, corn, wheat, barley flour, soybean, oil seed meal, fish meal, bone powder, grass meal, hay meal, etc |

| Type | flat die type and ring die type |

| Final Pellet Size | 2-10 mm |

| Application | animal and poultry feed pellets |

| Used For | chicken feed, bird feed |

Working video of poultry feed pellet plant

What is a Poultry Feed Pellet Plant?

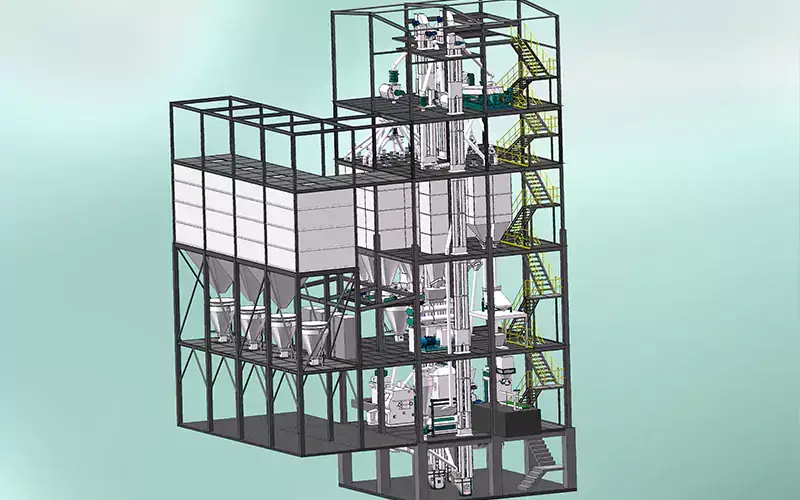

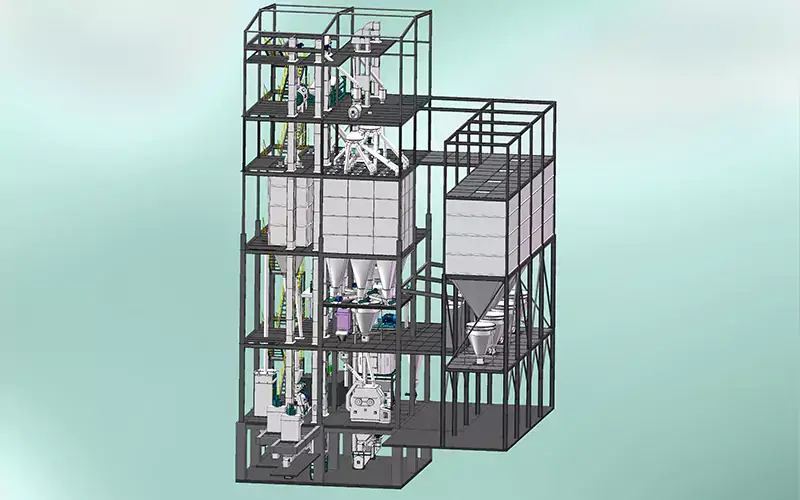

It’s important to understand that a poultry feed pellet plant is more than just a single machine. It is a complete, integrated facility. It has a series of interconnected machines and systems. These are all designed for the efficient and consistent production of poultry feed pellets, from processing the raw ingredients to bagging the finished product.

A “plant” is different from small-scale, on-farm pelleting. A plant usually means you have a higher production capacity. It often has more automation. It also has the ability to handle a wider range of processes and quality control measures for your feed.

Typical Price Ranges for a Complete Poultry Feed Pellet Plant

You know that setting up a poultry feed pellet plant is a smart move to control costs, but the biggest question is always the first one: “How much is this actually going to cost?” The price isn’t a single number; it’s a result of the choices you make.

t is important to remember that these are general estimates. The final price can change based on the supplier, the quality of the machines, and other factors.

- Small-Scale Plant (e.g., 1-2 tons/hr) A small but complete plant in this range might cost between $10,000 and $30,000 USD. This price typically covers the core machinery for a semi-automated production line.

- Medium-Scale Plant (e.g., 3-5 tons/hr) For a medium-sized operation, you can expect the cost to be in the range of $30,000 to $50,000 USD. This price range often includes better automation and more robust, durable machinery.

- Large-Scale Commercial Plant (e.g., 10+ tons/hr) For a large, industrial-scale plant, the cost will be starting from $50,000 and can go up significantly from there. This involves industrial-grade equipment and full automation.

The Scale and Capacity of Your Poultry Feed Plant (Tons/Hour)

The biggest driver of the cost of a plant is its size. A plant designed to produce 5 tons of feed per hour will require much larger, more powerful, and more expensive machinery than a plant that produces 1 ton per hour.

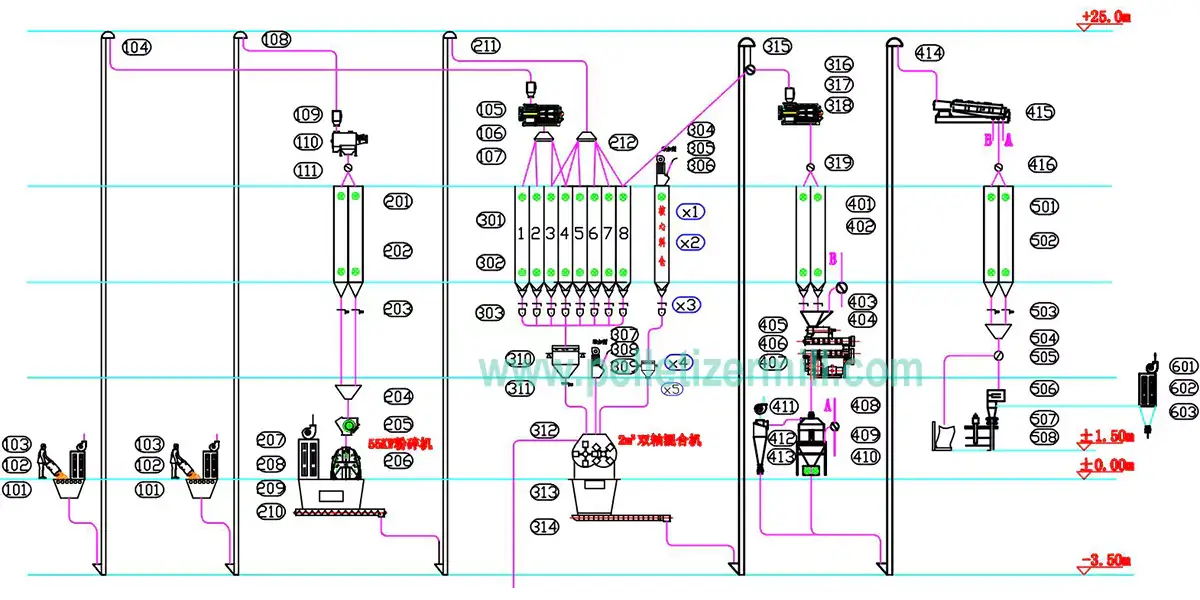

This affects every single machine in the line. A higher capacity means you need a larger intake pit, a bigger grinder with a more powerful motor, a larger mixer, a higher-capacity pellet mill, a bigger cooler, and a faster bagging system. Each of these larger machines adds to the total cost.

Your Level of Automation

How much of the work you want the machines to do by themselves also affects the price.

- Semi-Automatic Poultry Feed Plants (Lower Initial Cost) This type of plant involves more manual labor. For example, workers might be needed to move materials between machines or to handle the bagging process by hand. This lowers the initial machinery cost.

- Fully Automatic Poultry Feed Plants (Higher Initial Cost, Lower Labor Cost) These plants use a central PLC (Programmable Logic Controller) control system to manage the entire process. This reduces the number of workers needed to run the plant. However, the advanced control systems and extra conveying equipment significantly increase the initial investment.

The Specific Machinery You Choose

Your specific choices of machinery will also change the final price.

- The Pellet Mill Itself (Ring Die vs. Flat Die) For a plant, a ring die pellet mill is the standard choice. It is more expensive than a flat die mill, but it is also much more efficient for producing high volumes of feed.

- The “Optional” but Essential Machines. “A crumbler is essential for making starter feed for chicks. If you plan to serve that market, it’s a necessary cost. A good steam conditioner is also critical for making high-quality, digestible pellets, and it adds to the price of the pellet mill.”

- The Boiler and Other Support Systems. It is important to remember that the cost of a steam boiler, which is needed for the conditioner, is often a separate cost. Good dust collection systems are also an important part of the total plant price.

poultry feed manufacturing process flowchart

“Hidden” Costs to Include in Your Budget

Forgetting About Shipping, Customs, and Installation.

“The price you see on a supplier’s website is not the final price. You must add the costs of shipping the heavy machinery to your location. You also need to pay any import taxes or customs duties. And you need to budget for professional installation and commissioning.”

Budget for Spare Parts from Day One.

“Your pellet mill’s die and rollers are consumable parts; they will wear out with use. A smart business plan includes the cost of at least one or two replacement sets in the initial budget. This way, you are not surprised by this necessary expense later on.”

The Cost of a Proper Foundation and Electrical Setup.

“These are industrial machines. They need a solid concrete foundation to sit on. They also need a powerful three-phase electrical supply. The cost of preparing your site correctly is a real and significant part of the total plant cost.”

Conclusion

The price of a poultry feed pellet plant is not a single number. It is a range that depends on your choices. The final cost is determined by the plant’s capacity, the quality of the machinery you choose, and the level of automation you need. By understanding these key factors, you can create a realistic budget and make a smart investment that is perfectly tailored to your business goals.

FAQ

1. What’s the main difference between a single poultry feed machine and a full plant?

The main differences are scale, integration, and automation. A “machine” usually refers to a single, standalone pellet mill. A “plant” is a complete, integrated system of multiple machines, including grinders, mixers, coolers, and more. A plant is designed for higher, more consistent output with less manual labor, from raw material intake all the way to the finished, bagged feed.

2. Can I make both broiler and layer feed in the same plant?

Yes, absolutely. The same plant machinery is used for both. The key difference is between the poultry feed formulation and broiler feed formulation – the specific recipe of ingredients and their proportions. You would simply change the recipe that the plant is processing to switch between making broiler feed and layer feed. You might also change the pellet die size or the crumbler settings.

3. Why is a “crumbler” so important for a poultry feed plant?

A crumbler is essential because young chicks, for both broilers and layers, cannot eat full-sized pellets. A crumbler takes these finished pellets and gently breaks them into the ideal “crumble” size. This allows them to eat easily and get the nutrition they need for a strong start. It is much more efficient than trying to make tiny pellets directly in a large pellet mill.

4. How much does it cost to set up a small poultry feed pellet plant?

This can vary hugely. A small but complete plant (for example, one that makes 1-2 tons of feed per hour) is a very significant investment. The cost can range from tens of thousands to hundreds of thousands of US dollars. The final price depends on the level of automation, the quality of the machinery, and where it is made. It is essential to get detailed quotes from several different suppliers.

5. Do I need a nutritionist to run a feed plant?

While you don’t necessarily need a nutritionist on staff 24/7, you absolutely need to work with a qualified poultry nutritionist to create your feed formulations. They will help you create recipes that are safe, effective, and nutritionally balanced for your birds. This is not a step you should ever skip when making your own feed.