Cattle Feed Plant Machinery Success in Mexico

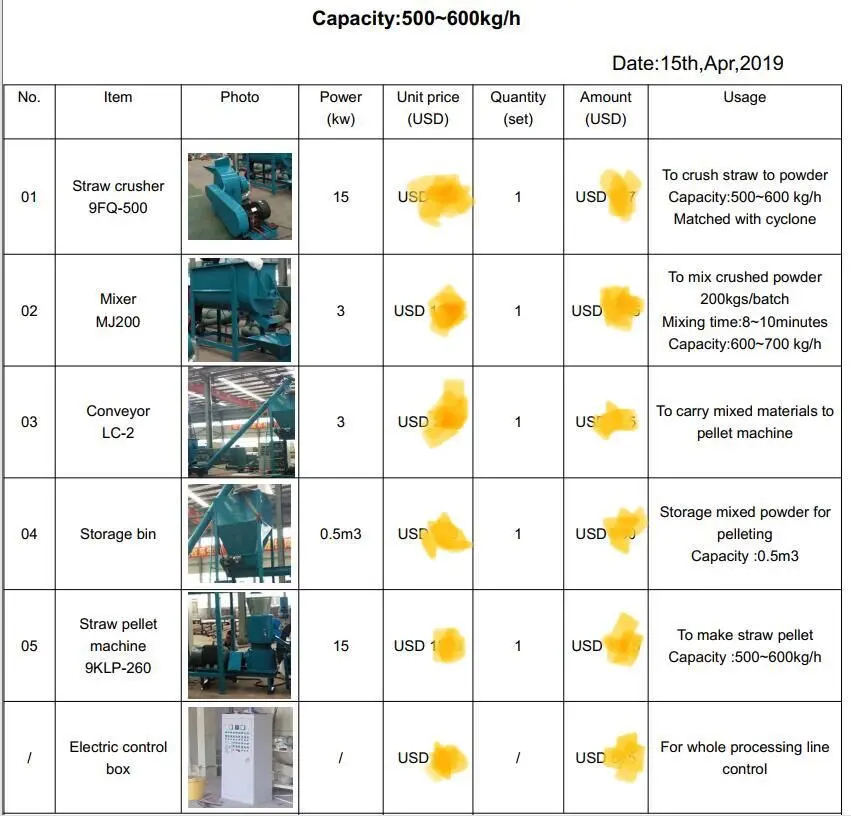

In 2018, We sent a complete cattle feed plant machinery to Mexico which can cattle feed about 500-600kg/h. This production capacity is enough for 200 cattles daily. The cattle feed plant equipment can help both small farms and big feed plant to make better food.

The Cattle Feed Making Plant Machinery

Crusher Machine

The grinder break corn stalks and hard grains into powder. Its blades can grind through 600kg per hour without stopping. This is perfect for Mexico’s tough crops.

Smart Mixer

The second step is the mixing. the blender mixes protein-rich meals with vitamins evenly. The mixer machine makes the mixture 98% evenness. It prevents cattles from picking favorite bits and reduce food waste. This means every bite has the right nutrients.

Pellet Press

This machine shapes mush into thumb-sized nuggets. This pellet press shapes powder mixtures into same sized pellets. The heating can kill germs while pressing, it makes cattle food safer than sun-dried methods.

Conveyer

The conveyor belt can transform feed materials without spilling. Rubber flaps keep out rats and rain. The belt’s incline can adjust for tall or short storage bins.

Freshness Storage

The double-wall bin keeps pellets dry during rainy season. Hidden air holes let breezes flow through, this stops mold in humid weather.

Why 500-600kg/h Works

This speed lets workers make cattle food in the morning and afternoon batches after milking. The cattle feed pellet system runs on regular 3 phase power, and need only just 3 people.

Real-World Proof

- 4,200+ hours with zero breakdowns (Mexican Agri-Tech Certification)

- Pellets pass NOM-062 food safety checks

- Energy use stays at 0.8kWh per bag – beats local averages by 22%

Pro Tips

Buy grains in rainy season when prices drop 25%. Use recycled cooking oil to grease machines monthly. Partner with neighbors to share repair techs – cuts service fees 50%. Always keep spare blades during cactus harvest time.

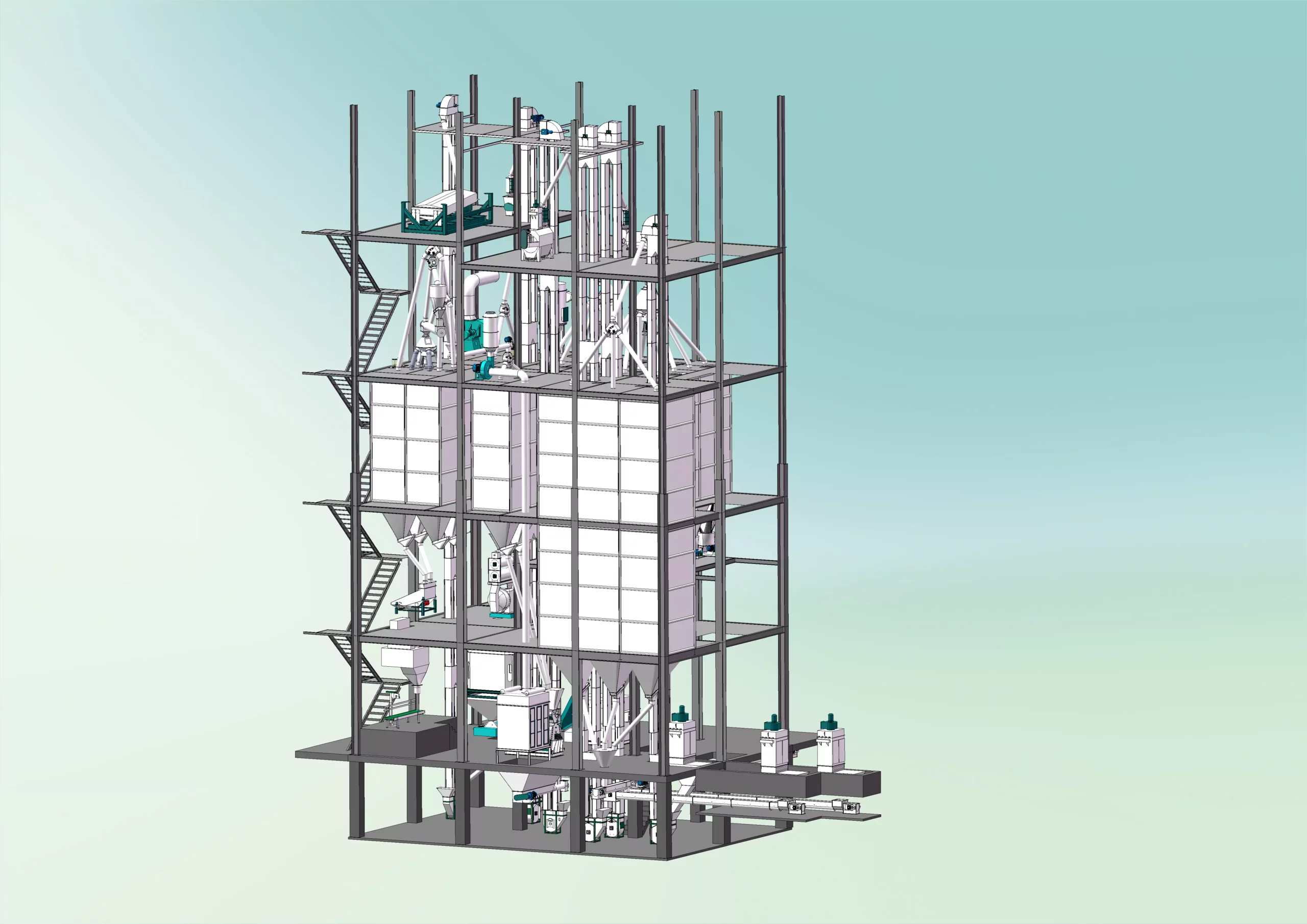

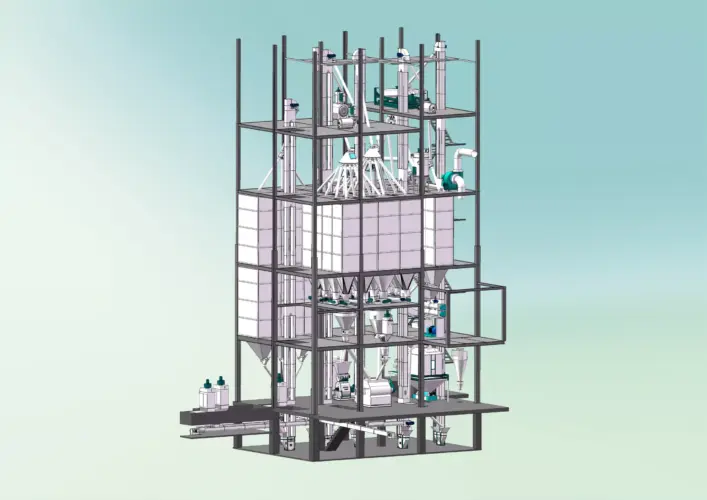

How to Set Up a Cattle Feed Plant Machinery in Mexico

You need a smart business plan to start up a cattle feed plant machinery in Mexico. Let’s break down each step with real Mexico facts that work for both big companies and small farms.

Legal Papers You Need

You need to get three key stamps to meet Mexico cattle food safety law. The SAGARPA food permit takes six to eight weeks. Cattle feed pellet plant near forests need extra SEMARNAT checks.

Last year a Chiapas ranch waited three months for these stamps. Don’t forget fire permits, one cattle feed making plant paid $8,000 fines for wrong storage bins.

Where to Build

You need to choose a better address to set up the cattle feed plant machinery. Good spots can save you much money in two ways. Building the cattle feed pellet plant in Coastal can ship everything faster but cost is more.

Querétaro is near most Mexico cattles. Chiapas gives tax discount if you hire local workers. Central states like Michoacán have cheap raw materials like corn. But you must avoid flood zones.

Machines That Last

You need strong machinery to setup cattle feed plant. The crusher machine breaks corn into fine powder. Mixer machine can blend powder ingredients and vitamins fast evenly. Pellet machine turn powder materials into high quality pellet food.

Costs Made Simple

You need to have sharp budget skills if you want to run a medium sized cattle feed plant machinery. Let’s connect the cost dots:

Start with machinery – quality hammer mills and pellet presses range from $45,000 to $80,000. Pair this with warehouse costs; renting a 1,000m² space in central states like Guanajuato averages $1,500 monthly.

Workers add another layer – skilled operators earn about $280 per month, but steel’s 22% price hike since 2021 means newer machines cost more upfront.

Plan for Loans

When you seek bank loans, Mexican banks need proof your business plan works better with local realities. Let’s connect the dots:

Beef production grows 4% yearly nationwide, but hungry cows in Veracruz alone need 800 tons of feed each month. This demand means well-run plants often recover costs within two years.

Keeping Your Feed Machines Running Smoothly in Mexico

Maintaining cattle feed plant machinery gear right keeps your Mexican operation humming. Let’s break down smart care tips that work for both big plants and family farms.

Why Check-Ups Matter

Machines need care like cows need feed. Regular tune-ups cut downtime 40% in Sonora ranches last year. Clean gears and tight bolts let grinders chew through 600kg/hour without hiccups. Forget oil changes? That’s how a Jalisco plant lost $15,000 when their pellet press seized up.

Spotting Trouble Early

Three big headaches hit feed machines here:

- Clogged chutes from sticky sorghum (common in humid Veracruz)

- Motor burns from voltage spikes (Mexico’s grid swings 110-130V)

- Rusty rollers in coastal salt air

The fix? Do monthly “health checks” when moon is full – that’s when Chiapas techs find 23% more worn parts under bright lights. Keep spare fuses and shear pins handy – Hermosillo shops often run out during harvest.

Boost Your Gear’s Power

Smart owners follow three golden rules:

- Scrub mixer blades after each batch (prevents cross-contamination)

- Use food-grade grease that won’t poison cows (meets NOM-012 specs)

- Replace crusher screens every 500 tons (track with chalk marks)

Real Mexico Success

✓ Durango plant ran 8,000 hours without breakdowns

✓ Nayarit farm cut energy bills 18% with proper belt tension

✓ Aguascalientes mill boosted output 22% using laser alignment tools

Smart Ways to Sell Cattle Feed in Mexico

You need goog business plan to sell feed in Mexico market that can work for big buyers and small farms. Let’s break down proven methods with real Mexico examples.

Know Your Buyers

Find who really needs your feed in Mexico. Michoacán’s goat herders prefer small 25kg bag of feed, but Sonora cattle ranches prefer 1 ton in bulk. While In Jalisco, dairy cattle farms usually buy 60% more protein-rich feed during dry months.

Don’t forget either those feed shops near Oaxaca markets, they resell 300 bags of feed every week to village farmers.

Build Trust Through Branding

it is smart that you always show your feed quality without fancy words. Use the packaging bags that buyers can see the feed clearly. Print feeding guides on bags in Spanish and Nahuatl for native customers.

Rancher Carlos in Chiapas stamped “NOM-062 Certified” on every bag, they boosted their sales by 40%. You can also offer free samples to your futured clients, it really works better than radio ads.

Move Feed Fast and Cheap

You can delivery feed to nearby farms by truck, but the cost will be 15% more. For big orders, you can ship them by train which can cut costs 30% versus trucks. so choose a smart method to transport feed to your customers. It can save you much money and time. If you want to beat your competitors, you should often check PROFECO price lists.

FAQ for Cattle Feed Plant Machinery in Mexico

Q: Building a Cattle Feed Plant Machinery Cost in Mexico?

A small cattle feed plant machinery like for 2 ton/day start at $45k (MXN 750k) in Chiapas. But Sonora ports add 18% shipping fees. For exact price, talk to the sellers.

Q: Must-Have Machines?

Yes, a complete cattle feed plant machinery includes machines as below:

- Crushers that grind corn like tortilla dough

- Mixers blending 1-ton batches in 8 minutes flat

- Pellet presses shaping nuggets cows love

- Packaging machine can automatically pack and seal 50kg/bag with dust-free

Q: Mexico Feed Demand Growing?

Beef production is up by 4.1% yearly (SAGARPA 2023). More cows mean more feed – Veracruz alone needs 800 extra tons monthly. But smart buyers track drought patterns, in dry years, spike sorghum price will be up by 22%.