Introduction

Not all fish feed at the surface of the water. For important bottom-dwelling species like shrimp and many types of catfish, the food needs to get down to them on the floor of the pond or tank. This is why understanding the sinking fish feed production process is so important for many aquaculture farmers.

This guide provides a clear, step-by-step look at how dense, water-stable sinking pellets are made. We will cover the journey from raw ingredients to the finished product. We will explain the key steps and the specific machinery involved in this important manufacturing process.

Why Sinking Feed? Which Fish Need It?

The Goal: Delivering Nutrition to the Bottom

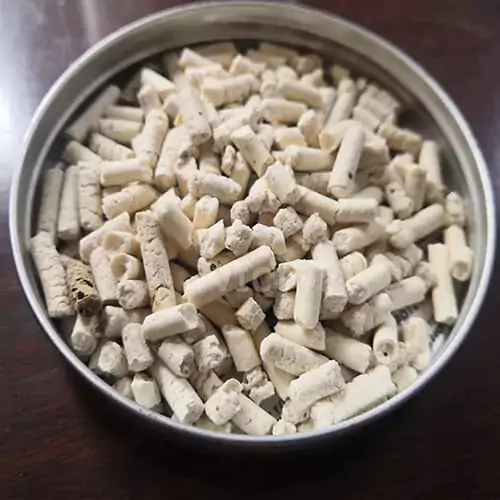

The main goal of sinking fish feed production process is to create a dense pellet. This pellet must sink quickly. It must also stay intact on the bottom for some time. This gives the bottom-feeding animals enough time to find and eat their food before it dissolves.

Common Species that Thrive on Sinking Feed:

Sinking feed is the best choice for any aquatic animal that naturally feeds at the bottom. This includes many commercially important species such as:

- Shrimp and Prawns

- Many species of Catfish

- Carp

- Sturgeon

The Sinking Fish Feed Production Process: A Step-by-Step Guide

Making high-quality sinking feed is a process with several important stages. Each step builds on the last one.

Step 1: Preparing Your Raw Ingredients

The process begins before any machine is turned on. First, you must have a good sinking fish feed formulation, or recipe. This recipe must have the right ingredients to meet the nutritional needs of your specific fish or shrimp. It is also important to check your raw materials for quality at this stage.

Step 2: Grinding the Ingredients

The first action is to grind all your dry ingredients. This is done using a hammer mill or a similar grinder. “The goal is to create a fine, consistent powder. A fine grind is crucial for creating a smooth mix. It also helps make a strong, dense pellet in the later stages.”

Step 3: Precise Mixing

All the ground powders and any micro-additives, like vitamins and binders, are then blended together. This is done in a feed mixer. This step is very important. It ensures that every single pellet you make will have the same balanced nutrition.

Step 4: Conditioning (The Key to Strong Pellets)

This is a critical step in sinking fish feed production process for making durable feed. The mixed mash is passed through a conditioner. Here, steam adds heat and moisture to the mix. This process starts to cook the starches in the feed. It also activates any binders in the recipe. This is essential for making a tough pellet that won’t fall apart easily in the water.

Step 5: Pelleting (Using a Pellet Mill)

This is the step that makes the feed sink. The warm, moist mash is fed into a fish feed pellet mill. This machine uses heavy rollers to force the mash through a metal plate with holes, called a die. This action compresses the mash into dense pellets. Unlike a feed extruder, a pellet mill does not trap air inside the pellet. This is why the finished pellets are heavy and sink.

Step 6: Drying and Cooling

The fresh pellets come out of the pellet mill hot. They also still contain extra moisture from the conditioning step. They are first moved to a dryer to reduce this moisture. This makes them safe for storage. Afterwards, they go to a cooler to harden and become stable.

Step 7: Sifting and Packing

Finally, the finished pellets are sifted to remove any dust or broken pieces. A packing machine then weighs the final, high-quality product and puts it into bags.

Sinking Fish Feed Formulation: A Nutritional Approach

The formulation of sinking fish feed plays a vital role in the health and growth of the fish. Organic ingredients and the right Fish Feed Pellet Size contribute to the feed’s efficiency. The process of sinking fish feed formulation is a sophisticated and critical phase that ensures the nutritional needs of different fish species are met.

Quality control is also pivotal in fish feed manufacturing. Sinking Fish Feed Quality Assurance Methods include laboratory testing for nutritional content, density checks, and sensory evaluation. These methods ensure that the feed adheres to industry standards and provides optimal nutrition.

This includes providing the right balance of proteins, fats, vitamins, minerals, and carbohydrates, in alignment with their specific life stage, weight, and environmental conditions. What process allows the fish food to sink? It’s a combination of density, moisture, and ingredients that provide the perfect sinking mechanism.

Selection of High-Quality Ingredients

The right balance of nutrients is achieved by selecting quality ingredients. Commonly used components include, In sinking fish feed formulation, selecting high-quality ingredients is vital to meet the nutritional needs of the target species. The following table provides detailed information about various components and their roles:

| Ingredient | Source | Role in Nutrition |

| Proteins | Fishmeal, soybean meal | Essential for growth, muscle development |

| Fats | Fish oil, soybean oil | Provides energy, supports cell function |

| Vitamins | Various supplements | Enhances immune system, metabolism |

| Minerals | Calcium, phosphorus | Supports bone health, physiological processes |

| Carbohydrates | Grains, cereals | Energy source, dietary fiber |

Nutritional Requirements by Fish Species

Different fish species have unique nutritional needs, and the formulation must align with these requirements. Below is a table sheet outlining specific nutritional requirements for different species:

| Fish Species | Proteins (%) | Fats (%) | Vitamins & Minerals | Carbohydrates (%) | Special Considerations |

| Salmon | 40-45 | 10-15 | Balanced | 15-20 | High omega-3 fatty acids |

| Tilapia | 32-38 | 6-10 | Balanced | 20-25 | Adequate protein-carbohydrate balance |

| Shrimp | 35-40 | 5-10 | Specific minerals | 15-20 | Requires specific amino acids |

Analyzing Nutritional Feed Solutions

Careful analysis ensures that the formulated feed meets the specific requirements:

Laboratory Analysis: Tests the nutritional value and quality of the feed.

Field Testing: Observes how fish respond to the feed in real conditions.

Sustainability Considerations: Ensures that the ingredients are sourced responsibly.

Key Factors for Making High-Quality Sinking Pellets

To make the best sinking pellets, you need to pay attention to a few key details in the process.

The Right Formulation with Good Binders

“Your recipe needs good binding ingredients. These can be things like starch or wheat gluten. They help the pellet stay together and not dissolve quickly when it’s in the water.”

A Very Fine Grind of Raw Materials

“A finer powder creates a denser, more tightly packed pellet. This results in a pellet that is more stable and durable in the water.”

Proper Conditioning with Steam

“Getting the right amount of steam, moisture, and temperature in the conditioner is often the real secret to making a tough, durable pellet that doesn’t just crumble into dust.”

Using the Right Pellet Mill Die

“Using a die with the correct hole size and compression ratio is important. It helps create the density and hardness needed for a good sinking pellet that lasts in the water.”

FAQ

What machine makes fish feed sink?

A: The main machine is the fish feed pellet mill. It uses pressure to compress feed into dense pellets that sink. This is different from a fish feed extruder, which is the machine used to make feed float.

How do I make my sinking pellets more stable in the water?

A: Three things are key to good water stability. First, use a very fine grind for your ingredients. Second, use a good binder (like wheat gluten or starch) in your feed formula. Third, ensure you have proper steam conditioning before the pelleting step to help cook and bind the ingredients together.

What’s the main difference between the process for sinking feed and floating feed?

A: The main difference is in the pellet-shaping step (Step 5). Sinking feed uses a pellet mill for compression. Floating feed uses a feed extruder for high-pressure cooking and expansion, which traps air in the pellet and makes it float.

Do I still need to dry sinking pellets after they are made?

A: Yes, absolutely. The conditioning step before pelleting adds a significant amount of moisture and heat to the feed. You must use a dryer to reduce this moisture to a safe level (usually below 12%). This makes the pellets hard and prevents mold during long-term storage.

What animals need sinking feed?

A: Any aquatic animal that naturally feeds at the bottom of a pond, tank, or raceway needs sinking feed. This includes most types of commercially farmed shrimp and prawns. It also includes many popular fish species like carp and some types of catfish.